Ingredient distributing element

A technology for dispensing components, bulk materials, applied in measuring devices, instruments, closures, etc., to solve problems such as unsuitable dispensing, small doses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

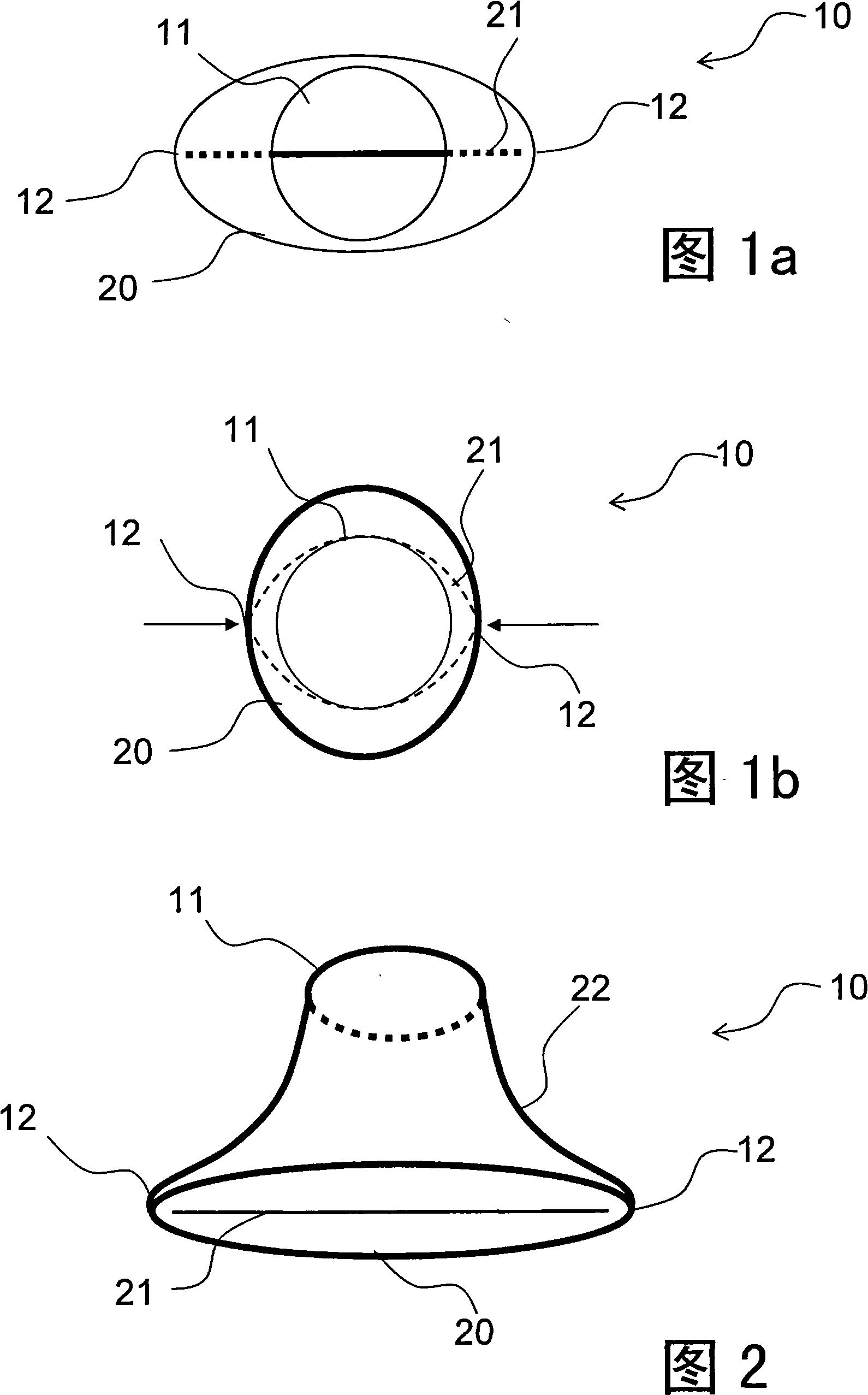

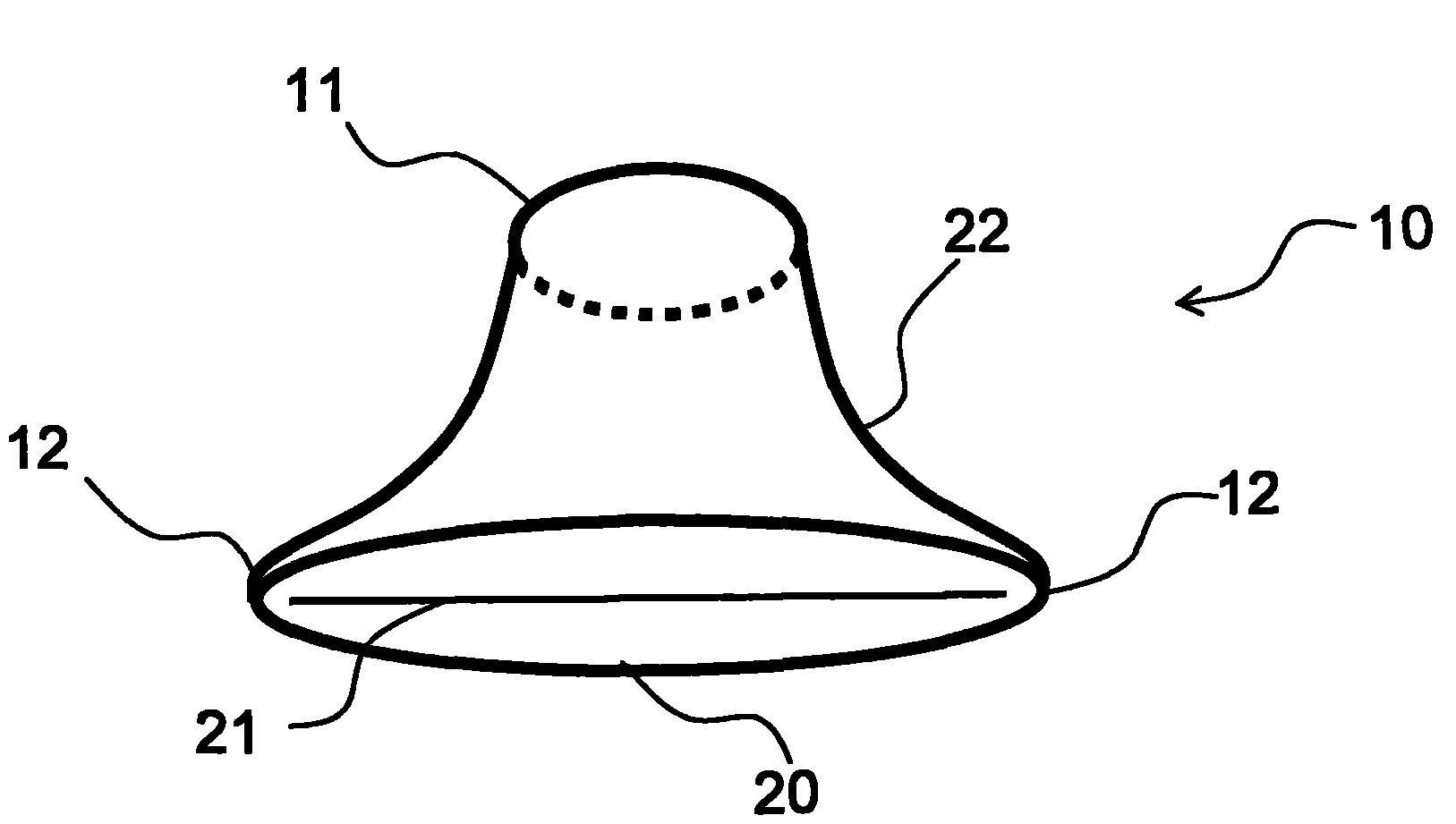

[0023] Figure 1a The ingredient-dispensing element 10 according to the invention is shown in plan view. Through the circular inlet opening 11 at the top here, the middle part of the outlet opening 21 can be seen, which is partly defined by the conical bell-shaped peripheral wall 22 of the ingredient dispensing element 10 (cf. figure 2 ) to cover. The discharge openings 21 are aligned along the major axis of the oval or oval region 20 . exist Figure 1a The slit-shaped outlet opening 21 in the illustrated embodiment is designed as a cutout in the oval surface area 20 such that it divides almost the entire oval area 20 . The oval region 20 remains uncut only around the circumference.

[0024] When the ingredient dispensing element 10 in this first figure is not compressed at the circumferential point 12 of the oval surface area 20, the oval shape of the surface area 20 of the ingredient dispensing element 10 on the opposite side of the inlet opening 11 becomes very obvious....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com