Spring set with stamped bent support ring

A technology of supporting rings and spring groups, applied in springs, low internal friction springs, springs/shock absorbers, etc., can solve the problem of high material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0115] The drawings are of a schematic nature only and are only used for the understanding of the invention. The same elements have the same reference numerals.

[0116] The features of individual embodiments can be implemented in other embodiments as well. Therefore, they are interchangeable.

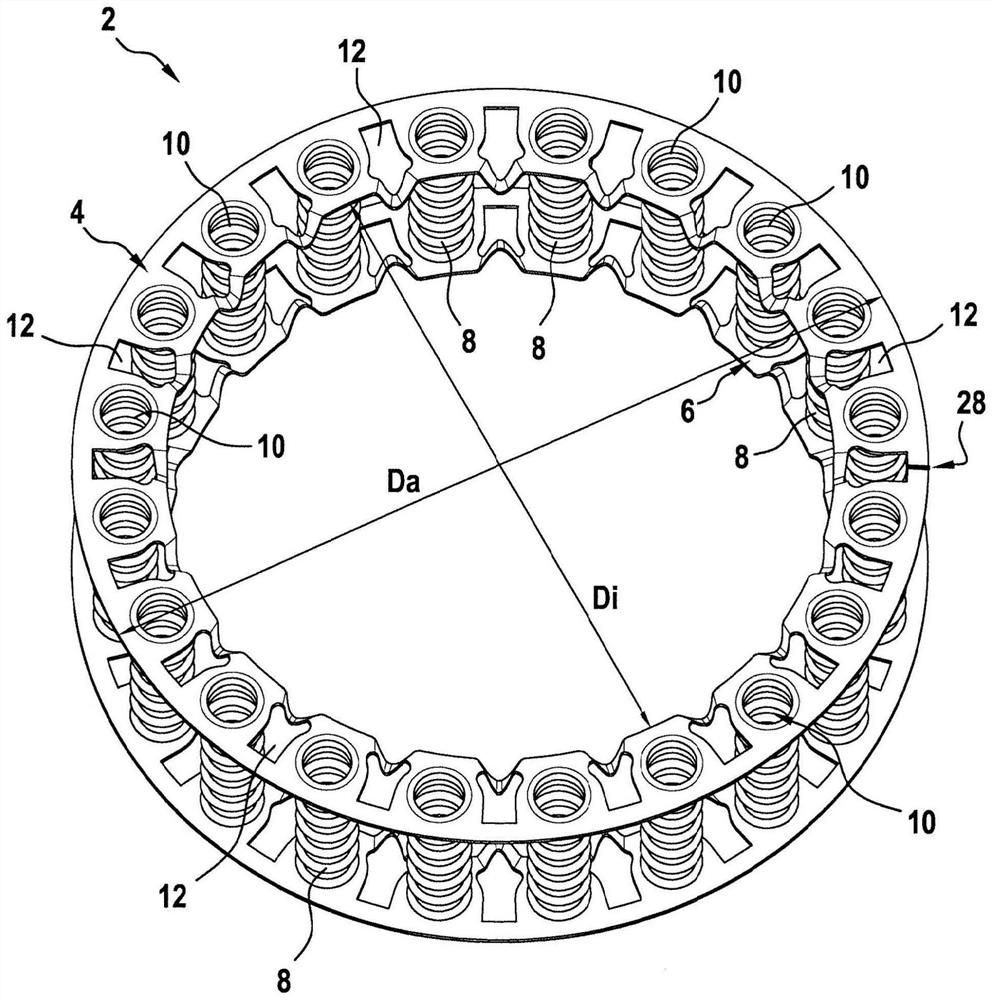

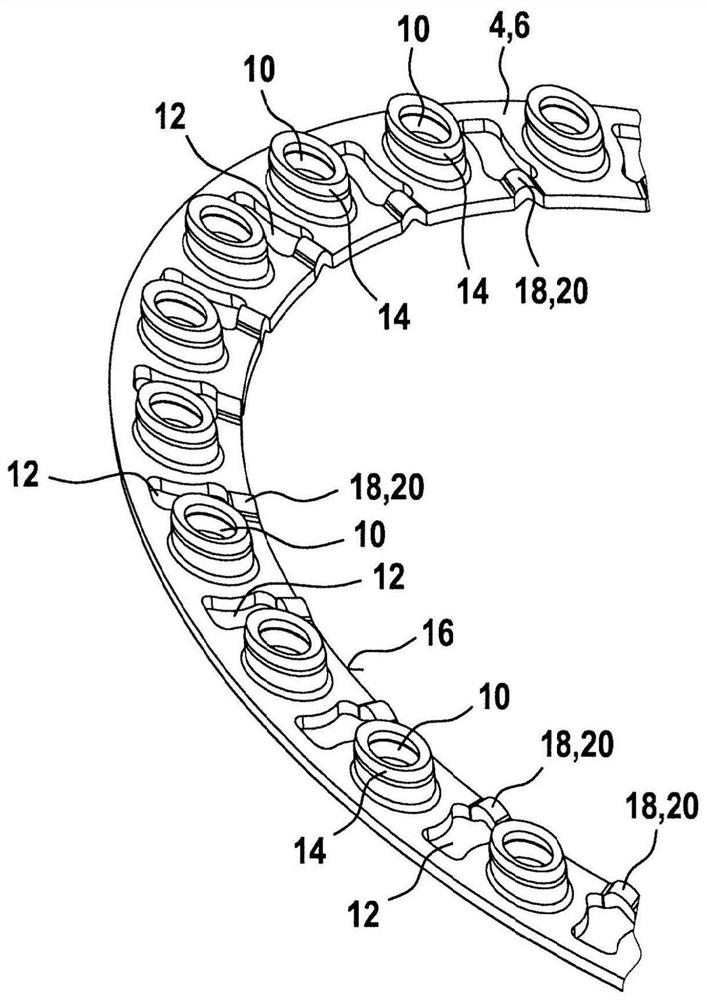

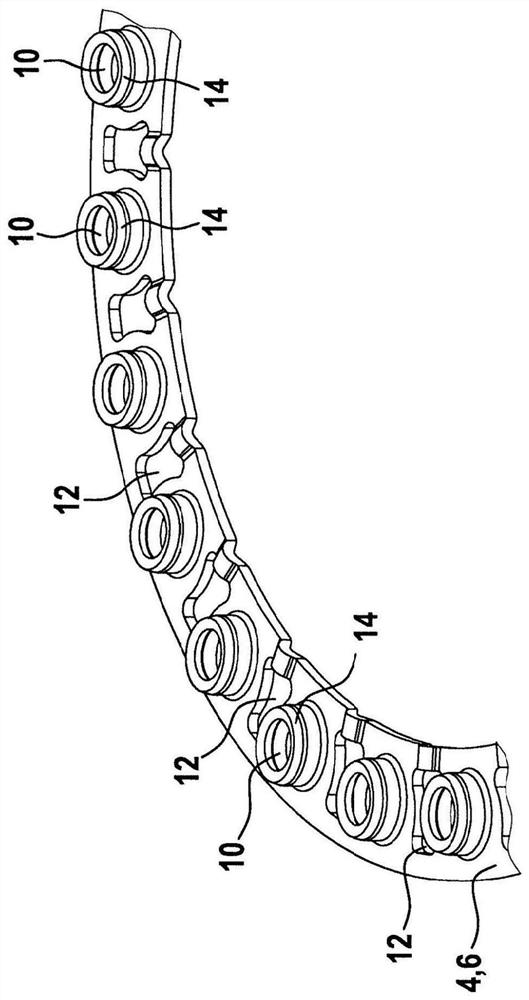

[0117] figure 1 The spring set 2 of the invention is shown in a first exemplary embodiment. The spring set 2 comprises a first support ring 4 , a second support ring 6 and a plurality of coil springs 8 arranged between the first and second support rings 4 , 6 .

[0118] The coil springs 8 can be formed as tension springs or compression springs and, in the embodiment shown here, are evenly distributed along the circumference of the two support rings 4 , 6 and are arranged spaced apart from each other. Furthermore, it can be seen that the support rings 4 , 6 have a circular opening 10 aligned with the central axis of each coil spring 8 . Between two such adjacent circular openings 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com