A kind of preparation method of high-strength mgb2 wire rod

A wire rod and high-strength technology, which is applied in the direction of cable/conductor manufacturing, electrical components, circuits, etc., can solve the problems of high stress in the center of the wire rod, synchronous extension, and poor performance, and achieve uniform deformation, delayed release, and fast plastic recovery. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Step 1. Mix amorphous boron powder, magnesium powder and amorphous carbon according to the atomic ratio of 1:1.95:0.05, and grind and mix them evenly under the protection of an argon atmosphere with a mass purity of 99.999% to obtain a precursor powder. The powder is put into the Nb / Cu composite tube, the two ends of the composite tube are blocked with cotton and one end of the composite tube is screwed tightly, and the composite tube is drawn at a processing rate of 10% to obtain a regular hexagon with an inscribed circle diameter of 3.56mm in cross section. Primary composite wire; the mass percentage of oxygen in the precursor powder is not more than 0.1%; in the Nb / Cu composite tube, Nb is used as an inner barrier layer, and Cu is used as an outer layer stabilizer;

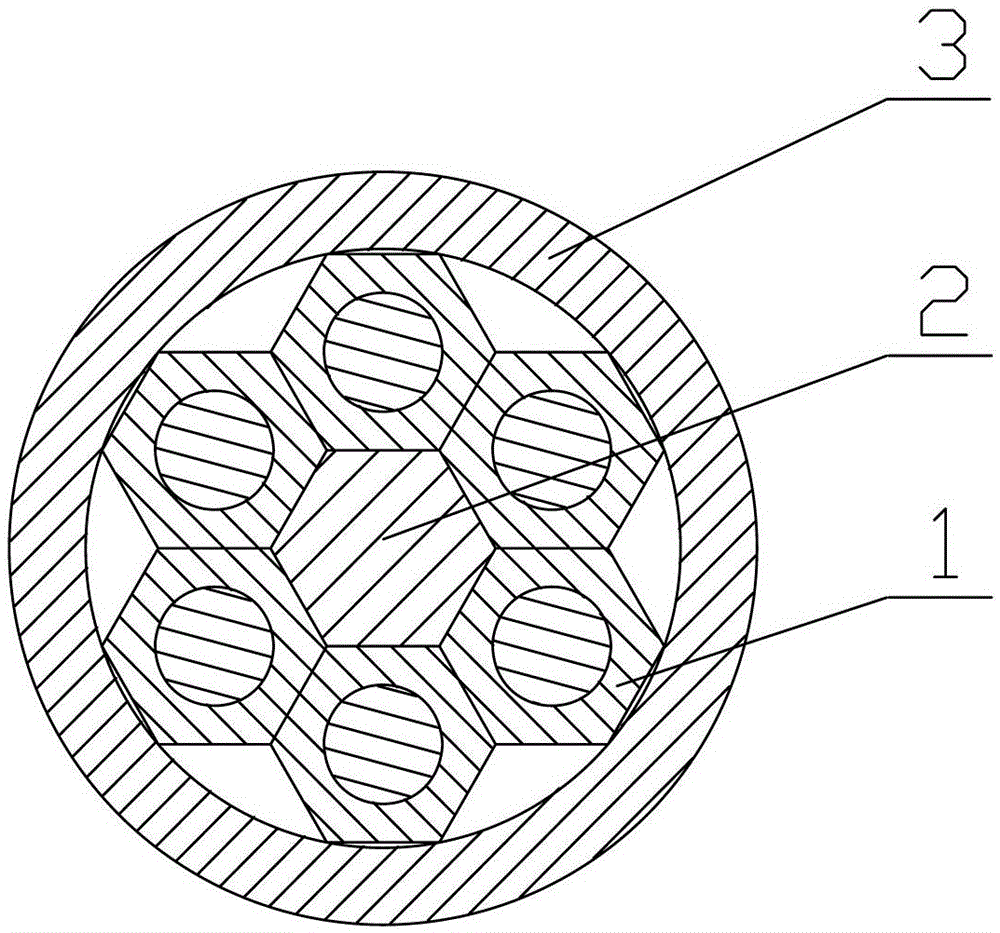

[0035] Step two, such as figure 1 As shown, a first CuAg alloy rod 2 having the same size as the primary composite wire 1 described in step 1 and 6 primary composite wires 1 were placed in an oxygen-free...

Embodiment 2

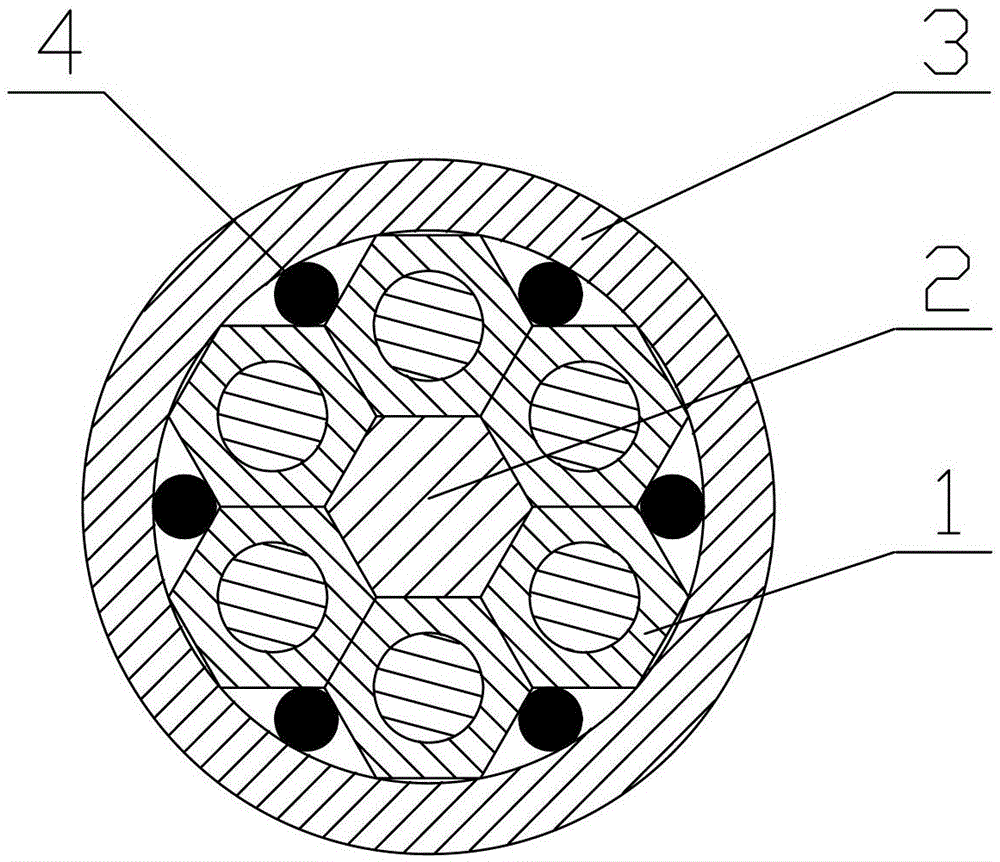

[0039] This embodiment is the same as Embodiment 1, and the difference is that the assembly method of the secondary composite pipe is as follows: figure 2 As shown, 1 first CuAg alloy rod 2 having the same size as the primary composite wire 1, 6 primary composite wires 1 and 6 second CuAg alloy rods 4 (circular cross section with a diameter of 0.89mm) were placed Assemble in the oxygen-free copper tube 3 to obtain a secondary composite tube; the second CuAg alloy rod 4 is located in the gap between two adjacent primary composite wires 1 and the oxygen-free copper tube 3; the second CuAg The volume percentage of Ag in alloy rod 4 is 18%, and the balance is Cu; the prepared high-strength MgB 2 The strength of the wire is 280MPa.

Embodiment 3

[0041] Step 1. Mix amorphous boron powder, magnesium powder and amorphous carbon according to the atomic ratio of 1:1.95:0.05, and grind and mix them evenly under the protection of an argon atmosphere with a mass purity of 99.999% to obtain a precursor powder. The powder is put into the Nb / Cu composite tube, the two ends of the composite tube are blocked with cotton and one end of the composite tube is screwed tightly, and the one end of the composite tube is pulled with a processing rate of 15% to obtain a circular primary composite wire with a cross-section of 3.56 mm in diameter; The mass percentage of oxygen in the precursor powder is not more than 0.1%; in the Nb / Cu composite tube, Nb is used as an inner barrier layer, and Cu is used as an outer layer stabilizer;

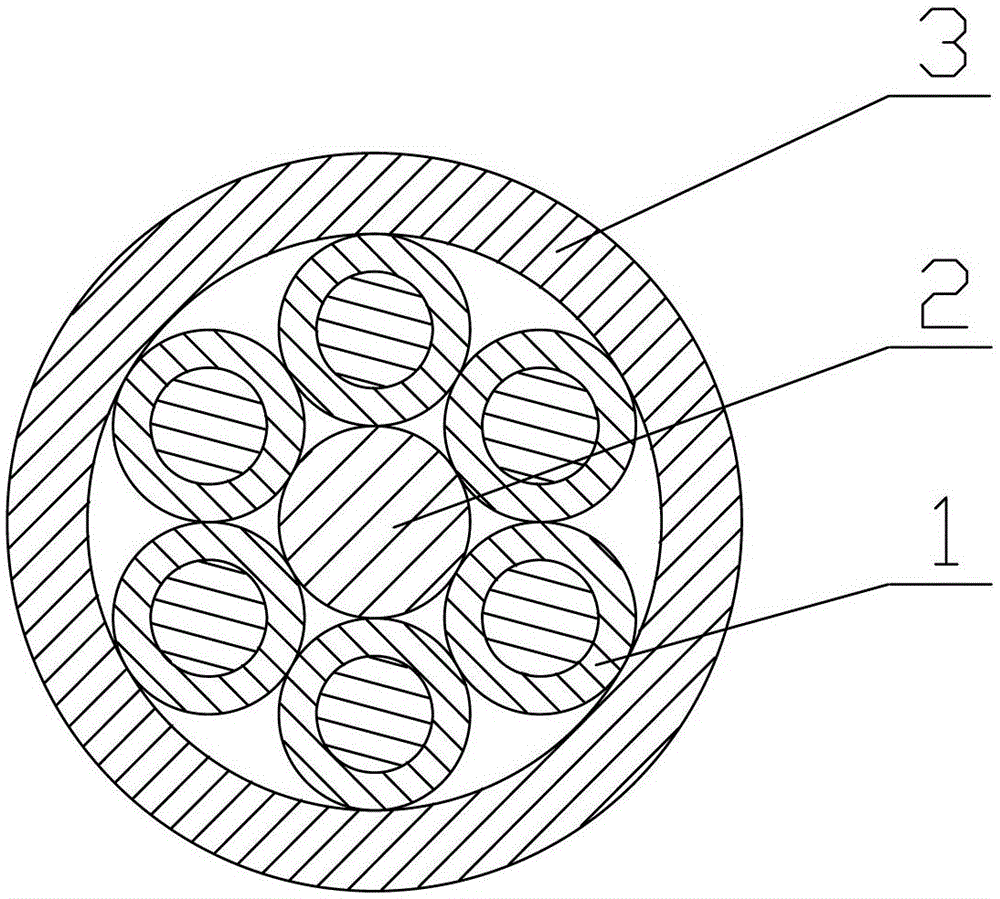

[0042] Step two, such as image 3 As shown, a first CuAg alloy rod 2 having the same size as the primary composite wire 1 described in step 1 and 6 primary composite wires 1 were placed in an oxygen-free copper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com