A spiral heat exchanger

A heat exchanger, spiral technology, applied in the field of using radially extending rods, can solve the problem of central axis deviation of heat exchangers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

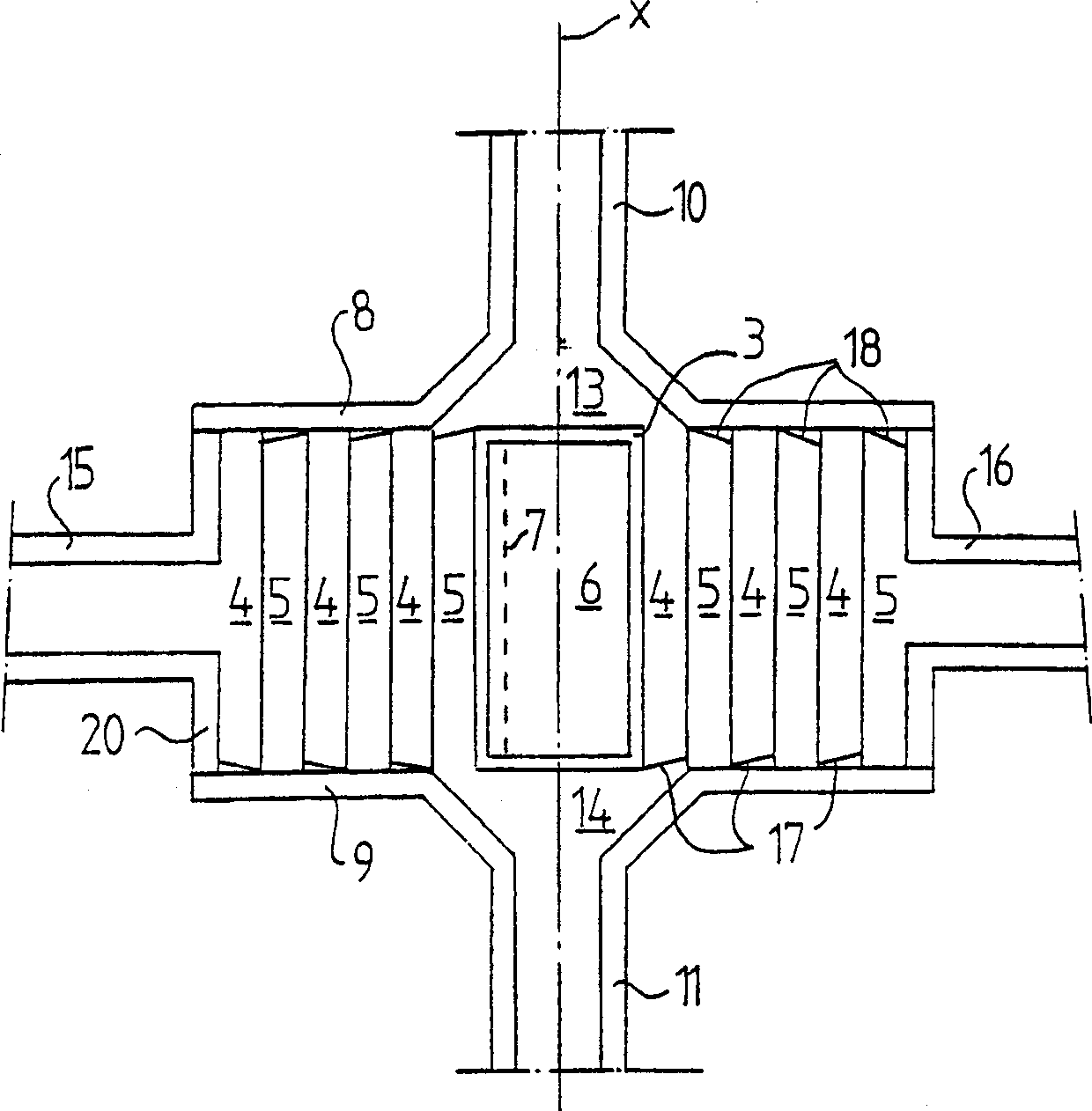

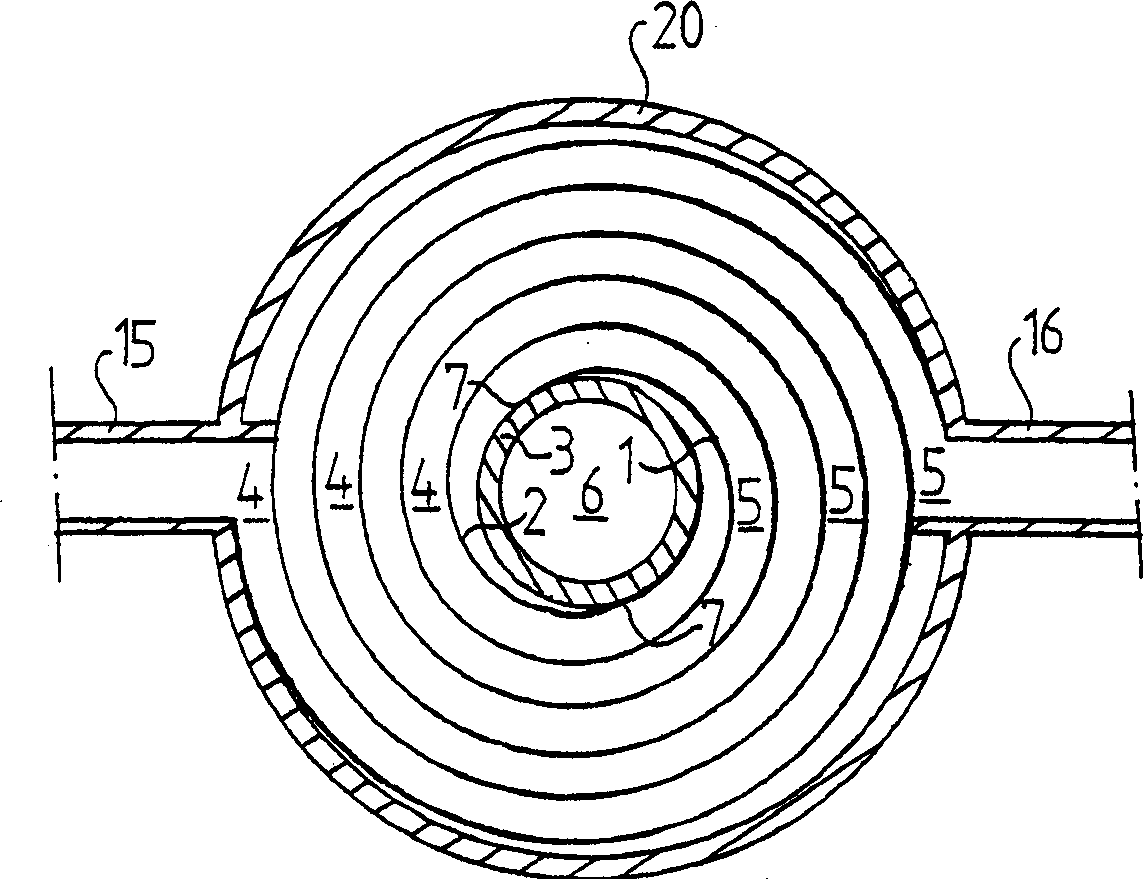

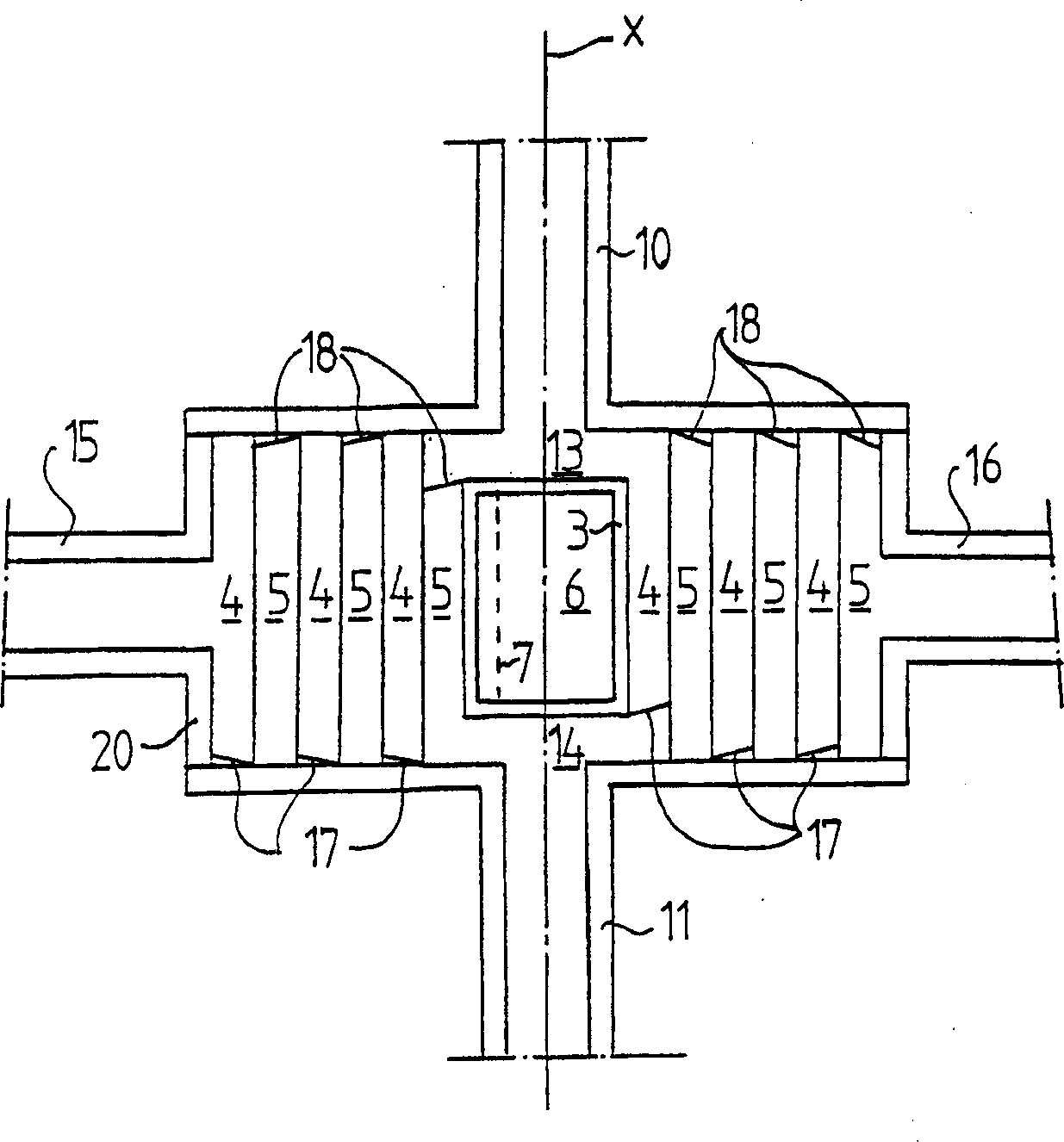

[0023] figure 1 and 2 A first embodiment of the helical heat exchanger of the present invention is schematically shown. The heat exchanger comprises two helical metal plates 1, 2 extending along respective helical paths around a common central axis x. The two helical metal plates 1, 2 are each connected to the central body 3 along a line 7 that is approximately parallel to the central axis x. from figure 2 It can be seen that the lines 7 are positioned diagonally opposite each other with respect to the central axis x. The central body 3 is cylindrical, its outer surface is continuous, and the outer surfaces are connected with spiral plates 1 and 2. The two helical metal plates 1, 2 can be welded to the central body 3 along lines 7, respectively, but other joining methods can also be used.

[0024] The two helical metal plates 1, 2 form two helical flow channels 4, 5 that are parallel to each other. The heat exchange fluid can flow in each flow channel in a direction tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com