Device for the volume-controlled portioning of cleaning fluid

A technology of clean fluid and volume control, applied in the field of cameras, can solve problems such as negative impact on working mode or accuracy, increased consumption, exceeding the volume of dosing, etc., and achieve the effect of improving accuracy and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

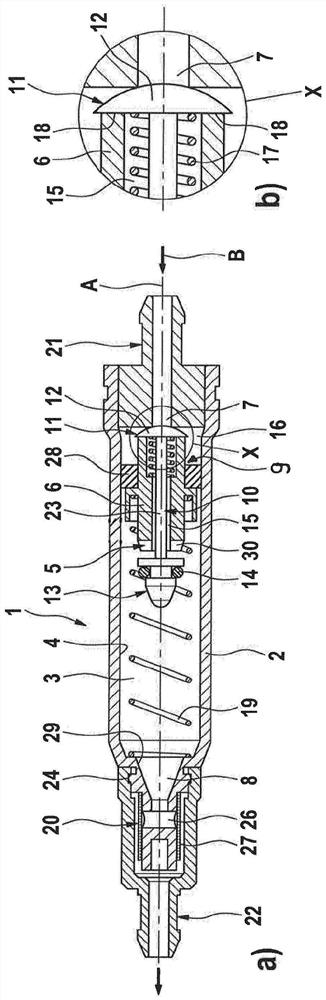

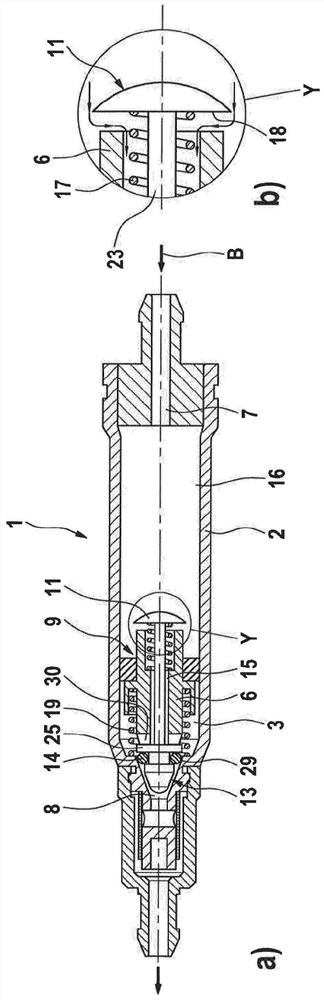

[0022] figure 1

[0023] The device 1 according to the invention is embodied substantially rotationally symmetrical about a central axis A and has an approximately sleeve-shaped housing 2 with a cavity 16 which can be filled with a cleaning fluid and which can The piston unit 9 moves along the center axis A and delimits the chamber 3 in the cavity 16 .

[0024] The inflow channel 7 , which opens into the cavity 16 , is hydraulically connected to a delivery device (not shown here) and serves to fill the cavity 16 with cleaning fluid under pressure.

[0025] The piston unit 9 is sealed radially against the side surface 4 of the cavity 16 by a sealing element 28 . When the pressure in the inflow channel 7 increases, the overpressure between the pressure upstream of the piston unit 9 in the actuating direction B relative to the pressure in the chamber 3 arranged downstream of the piston unit 9 increases. Via this pressure difference, the piston unit 9 is moved in a forward move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com