System component for a knitting system, and handling process

A technology of knitting system and components, which is applied in weft knitting, warp knitting, textiles and papermaking, etc., and can solve the problems of not setting auxiliary tools for knitting needles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

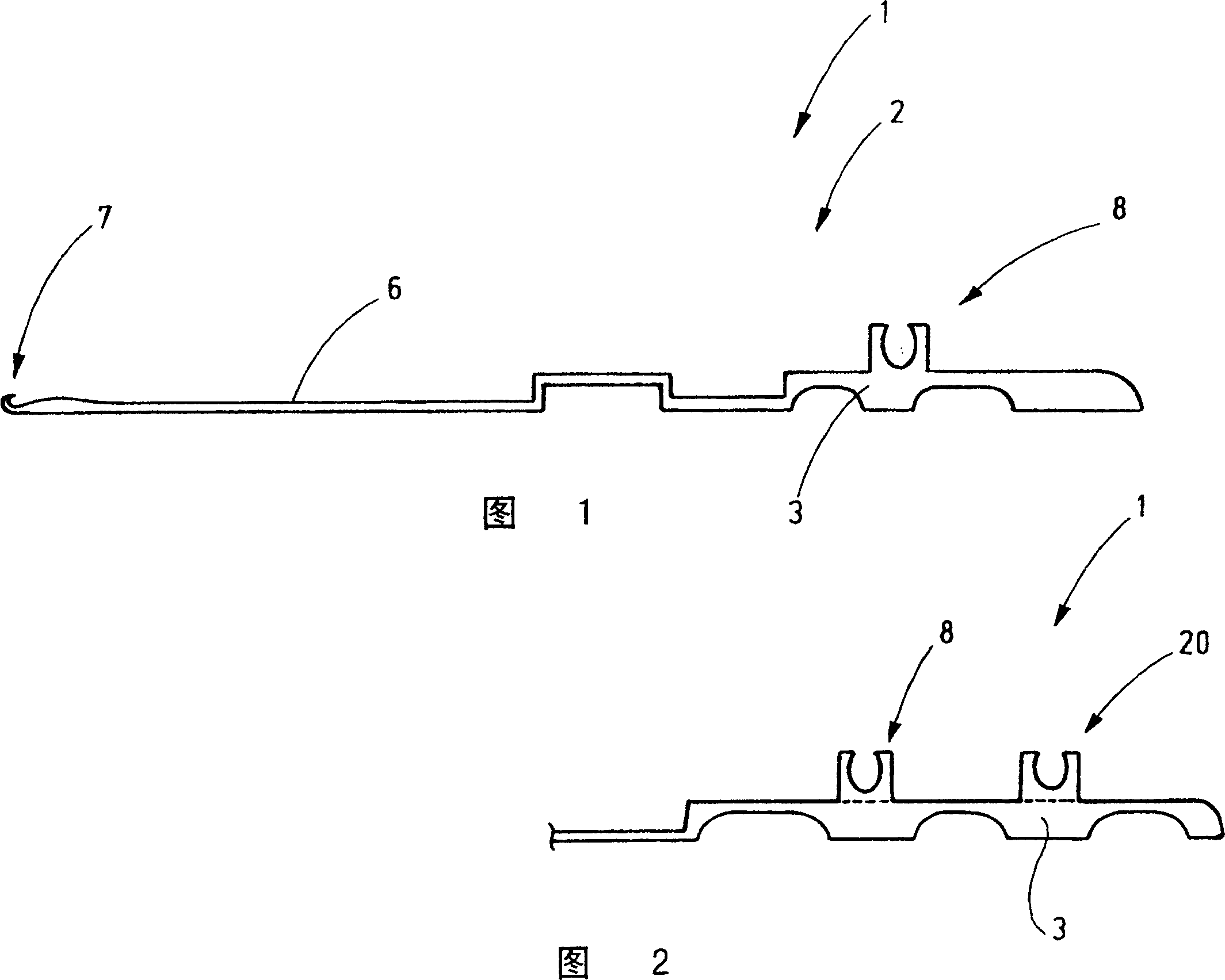

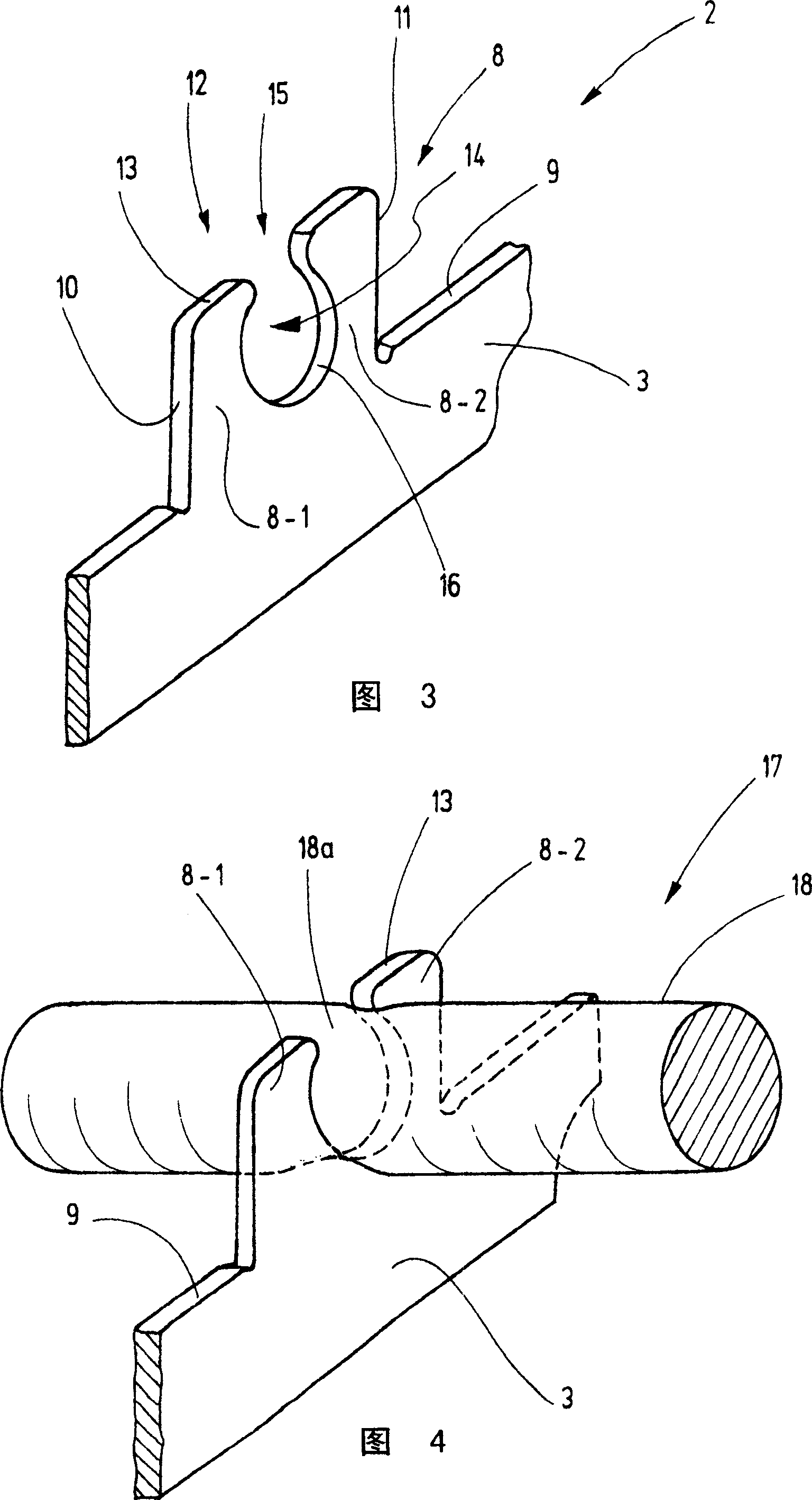

[0028] FIG. 1 shows as an example a system component 1 of a knitting machine using knitting machine needles 2 . The knitting machine needle 2 is for illustration only. The invention can also be implemented with other system components, eg sinkers, selection components or the like.

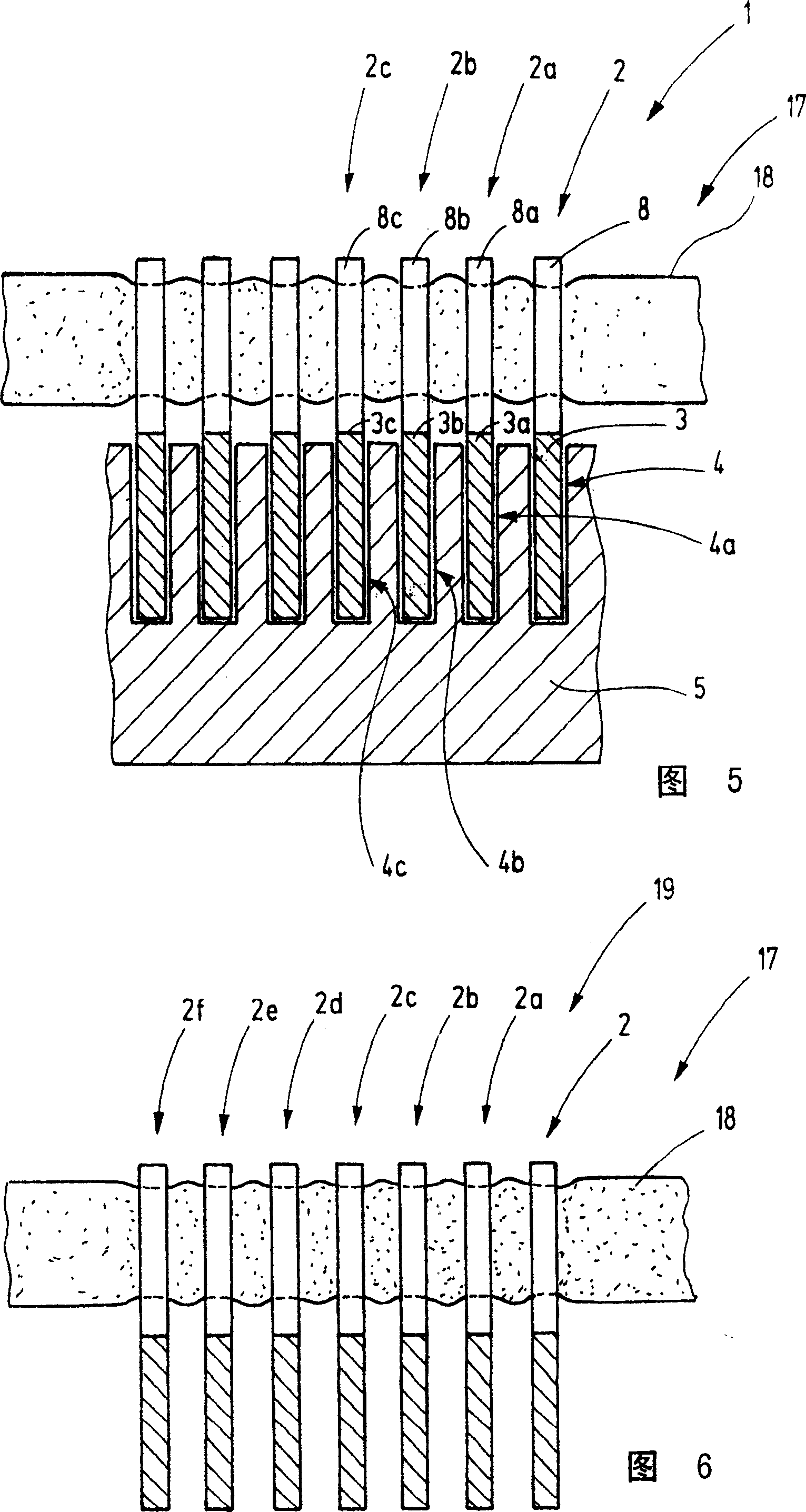

[0029] The knitting machine needle 2 has a body 3 which, as shown in FIG. 2 , is placed into a guide 4 of a needle bed 5 . The needle bed 5 is, for example, a flat bed of a flat knitting machine, a needle cylinder of a circular knitting machine or its dial. Said needle bed has a plurality of adjacent guide grooves 4, 4a, 4b, 4c, etc., wherein the bodies 3, 3a, 3b, 3c, etc. of the knitting machine needles 2, 2a, 2b, 2c, etc. are arranged in their longitudinal direction The way to be able to move is fixed.

[0030] The body 3 of the knitting machine needle 2 has a shaft 6 and on the end of said shaft a hook 7 or other functional part is provided. During operation, the knitting machine 2 performs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com