Double-drive heat pipe heat radiation cabinet

A dual-drive, heat pipe technology, applied in the field of cooling cabinets, can solve the problems of high power in a single cabinet, overheating in the computer room, and difficulty in installing air conditioners, and achieve the effects of increasing installed power, reducing operating energy consumption, and avoiding local overheating problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

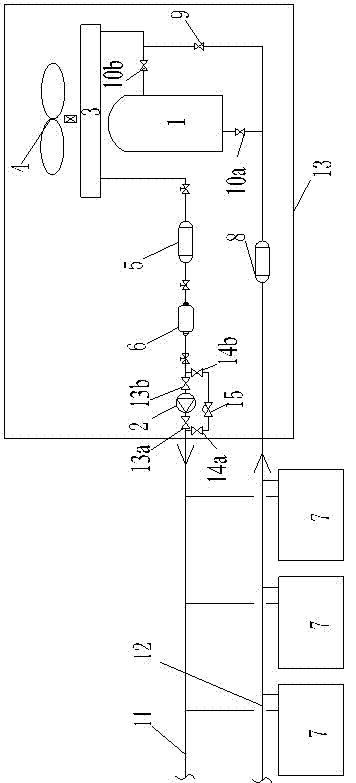

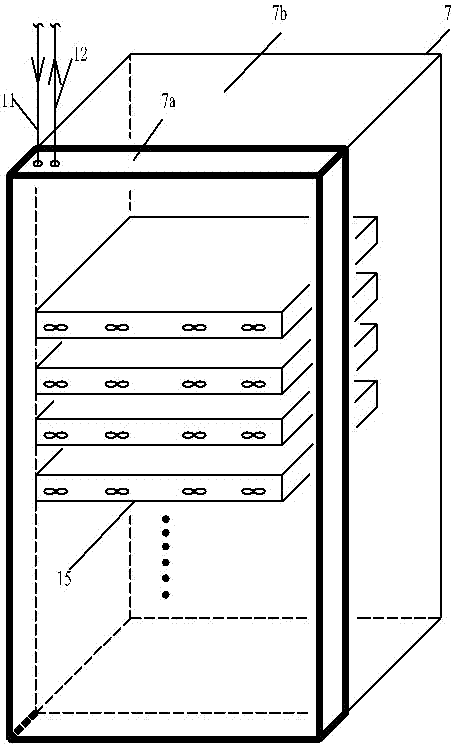

[0033] Such as figure 1 As shown, the compressor 1 and the fluorine pump 2 are connected in the pipeline system, and the compressor or the fluorine pump can be operated independently by switching the valve. The inlet and outlet of the compressor 1 are provided with a solenoid valve 10a and a solenoid valve 10b, wherein the solenoid valve 10a controls the entry and the solenoid valve 10b controls the exit. A solenoid valve 9 is provided in the bypass pipeline of the inlet and outlet of the compressor 1, and the bypass pipeline is arranged outside the solenoid valve 10a and the solenoid valve 10b, and is not controlled by the solenoid valve 10a and the solenoid valve 10b. The inlet and outlet of the fluorine pump 2 are provided with a solenoid valve 13a and a solenoid valve 13b, wherein the solenoid valve 13a controls the output and the solenoid valve 13b controls the input. A solenoid valve 14a and a solenoid valve 14b are arranged on the bypass pipe of the inlet and outlet of...

Embodiment 2

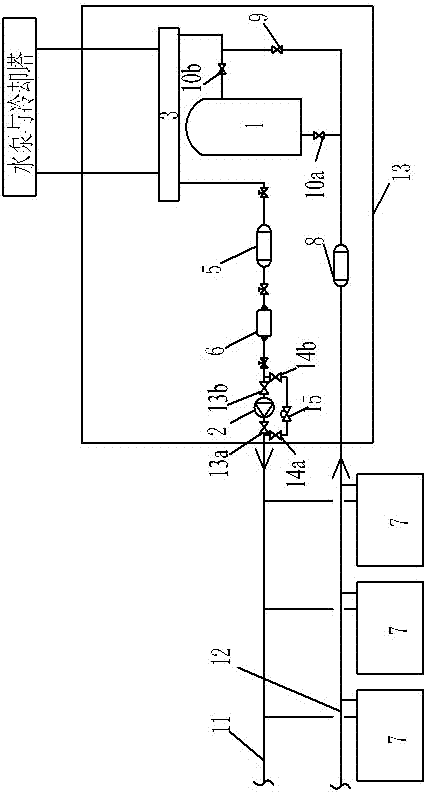

[0041] Such as figure 2 Shown, the difference between embodiment 2 and embodiment 1 is 3 heat exchangers, in embodiment 1 figure 1 The middle heat exchanger is a freon-air heat exchanger, so the fan 4. In this embodiment figure 2 The middle heat exchanger is a freon-water heat exchanger, so it needs an external water pipe to dissipate heat through a cooling tower, or use atomization spraying to dissipate heat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com