Aluminum-coated plate strip for kitchen ware and production method of aluminum-coated plate strip

A production method and technology for an aluminum-clad plate are applied to the aluminum-clad plate and strip for kitchen utensils and the production field thereof to achieve the effects of excellent aluminum-clad performance, good heat dissipation, and good stamping and deep-drawing processing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

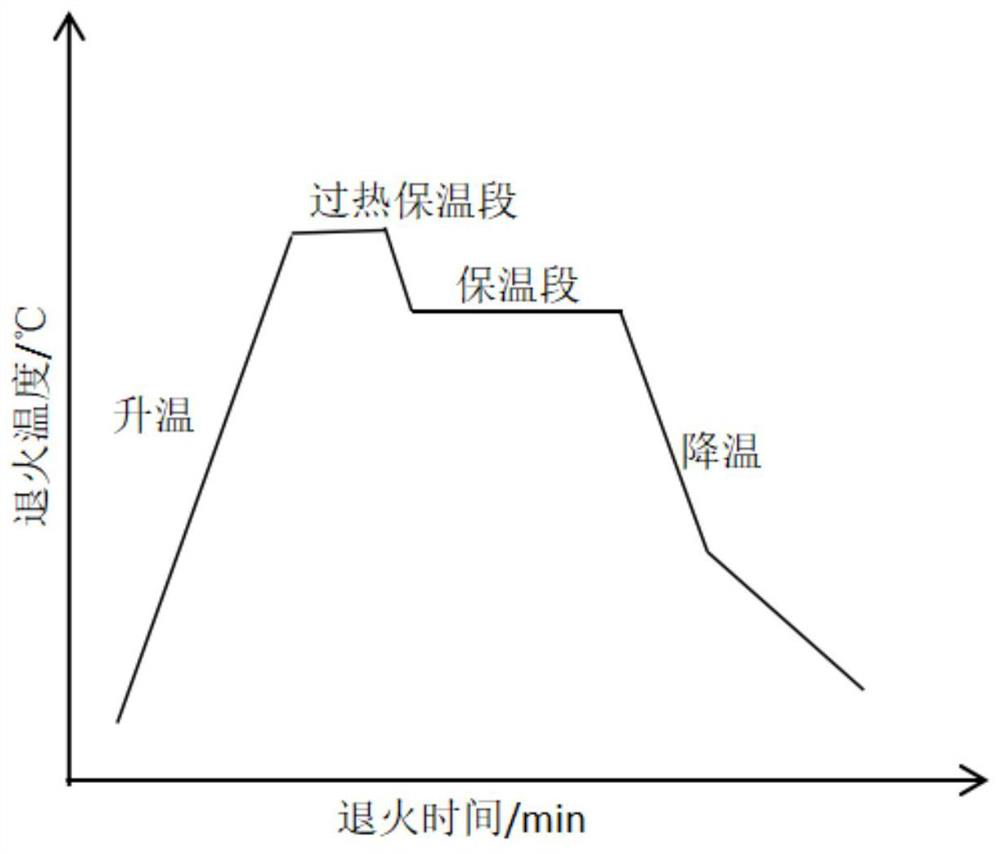

Method used

Image

Examples

Embodiment 1

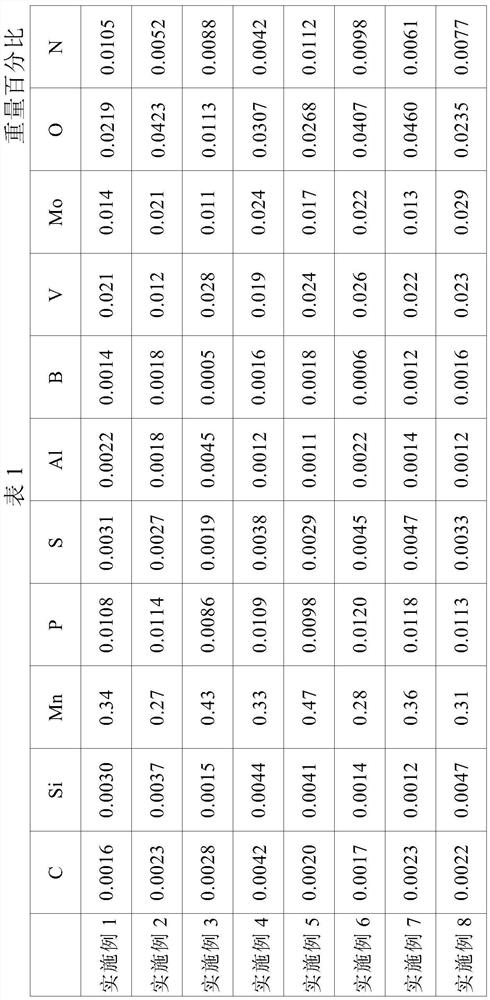

[0066] According to the chemical composition requirements of the aluminum-clad steel strips of the present invention, steel strips 1 and 2 of different specifications are selected, cleaned and polished, then rolled at room temperature and annealed to obtain steel-aluminum-steel aluminum-clad strips. The chemical composition of the aluminum-clad substrate is shown in Table 1, and the specific process parameters are shown in Table 2. The thickness of the strip is 1.0-2.5mm, and the thickness of the aluminum layer is 0.4-1.5mm. The performance of the finished product is shown in Table 3.

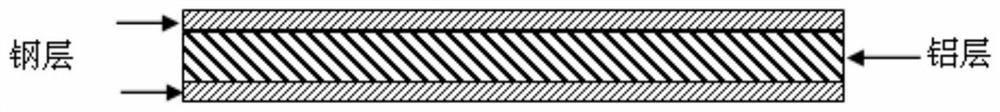

[0067] see figure 2 , which is a schematic structural view of an embodiment of the aluminum-clad strip according to the present invention. In this embodiment, the aluminum-clad strip is a steel-aluminum-steel structure.

[0068] The tensile strength of the aluminum-clad sheet strip prepared by adopting the composition and process described in the invention exceeds 320MPa, and the elongation ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com