Electric control water pump control method and ECU

A technology of electronically controlled water pumps and control methods, which is applied in pump control, liquid variable displacement machinery, exhaust gas recirculation, etc., and can solve problems such as overheating of EGR coolers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] By way of the above drawings, specific embodiments of the invention have been shown and will be described in more detail hereinafter. These drawings and written descriptions are not intended to limit the scope of the inventive concept in any way, but to illustrate the inventive concept for those skilled in the art by referring to specific embodiments.

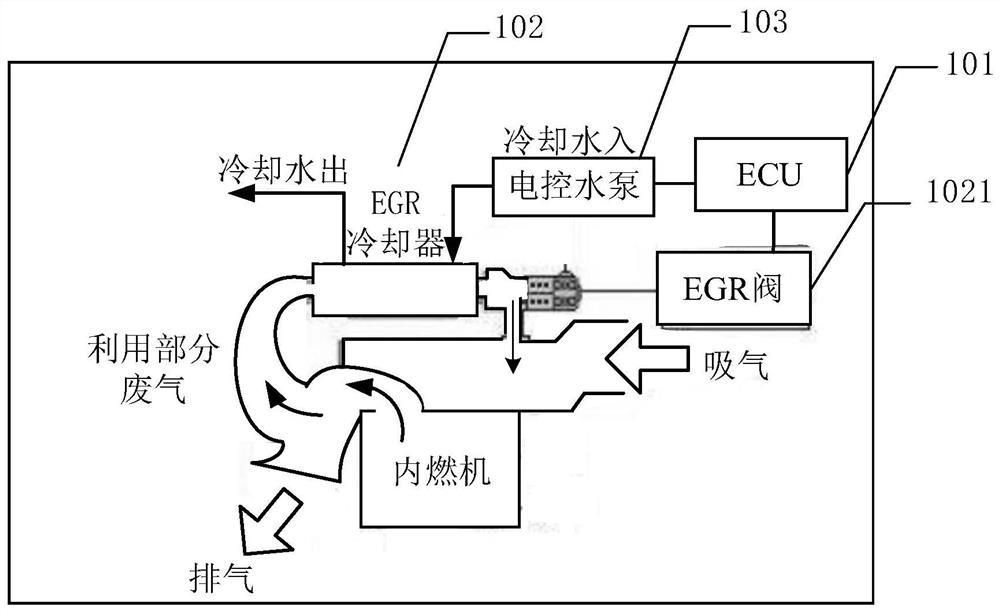

[0041] figure 1 The schematic structural diagram of the EGR system provided by the embodiment of the present invention, such as figure 1 As shown: the EGR system in the embodiment of the present invention includes: an electronic control unit (Electronic Control Unit, ECU) 101 , an EGR cooler 102 and an electronically controlled water pump 103 . Wherein the EGR cooler 102 further includes an EGR valve 1021 . The ECU 101 controls the rotational speed of the electronically controlled water pump 103 and the opening of the EGR valve 1021 , and the EGR cooler 102 cools the recovered exhaust gas through the cold water provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com