Technique for laser cutting metal tube utilizing compressed air and apparatus thereof

A compressed air and laser cutting technology, which is applied in the field of laser applications, can solve the problems of focusing lens deformation, increased manufacturing cost, and high cost, and achieve the effects of preventing local overheating, saving oxygen consumption, and reducing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

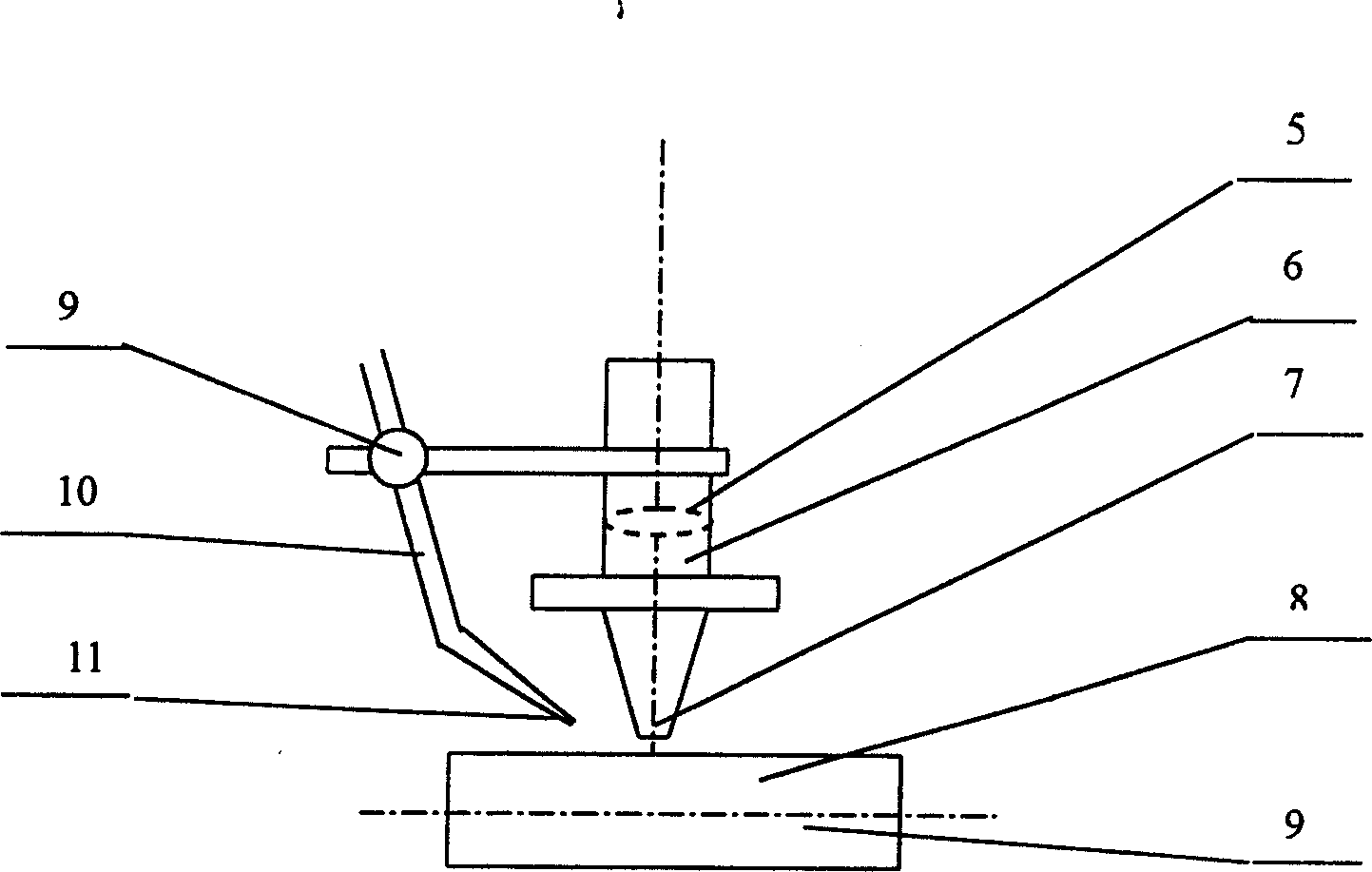

[0010] The invention consists of figure 2 The shown laser cutting head device implements the process of introducing compressed air into the laser cutting metal pipe. The oxygen pressure used is 0.18MPa, and the angle between the compressed air nozzle 11 and the oxygen nozzle 7 is 45°. The air pressure is 0.35MPa, the distance between the compressed air nozzle 11 and the oxygen nozzle 7 is 20mm, and the distance between the compressed air nozzle 11 and the workpiece 8 to be cut is 8mm.

[0011] figure 2 As shown in the laser cutting head device, the laser adopts CO2 axial flow laser, the material of compressed air nozzle 10 and nozzle 11 is made of pure copper, the inner diameter of nozzle 10 is Φ8mm, the outer diameter is Φ10mm, and the outlet diameter of nozzle 11 is Φ3 .2mm, the nozzle 10 and the nozzle 11 are connected by brazing, the direction of the compressed air nozzle 11 forms an angle of 45° with the oxygen nozzle 7, the distance between the compressed air nozzle 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com