Compound insulation-based low-sense busbar

A low-inductance busbar and composite insulation technology, which is applied in the direction of insulated cables, insulated conductors, conductors, etc., can solve the problems of low-inductance busbar design, high cost, and rapid aging of the insulation layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

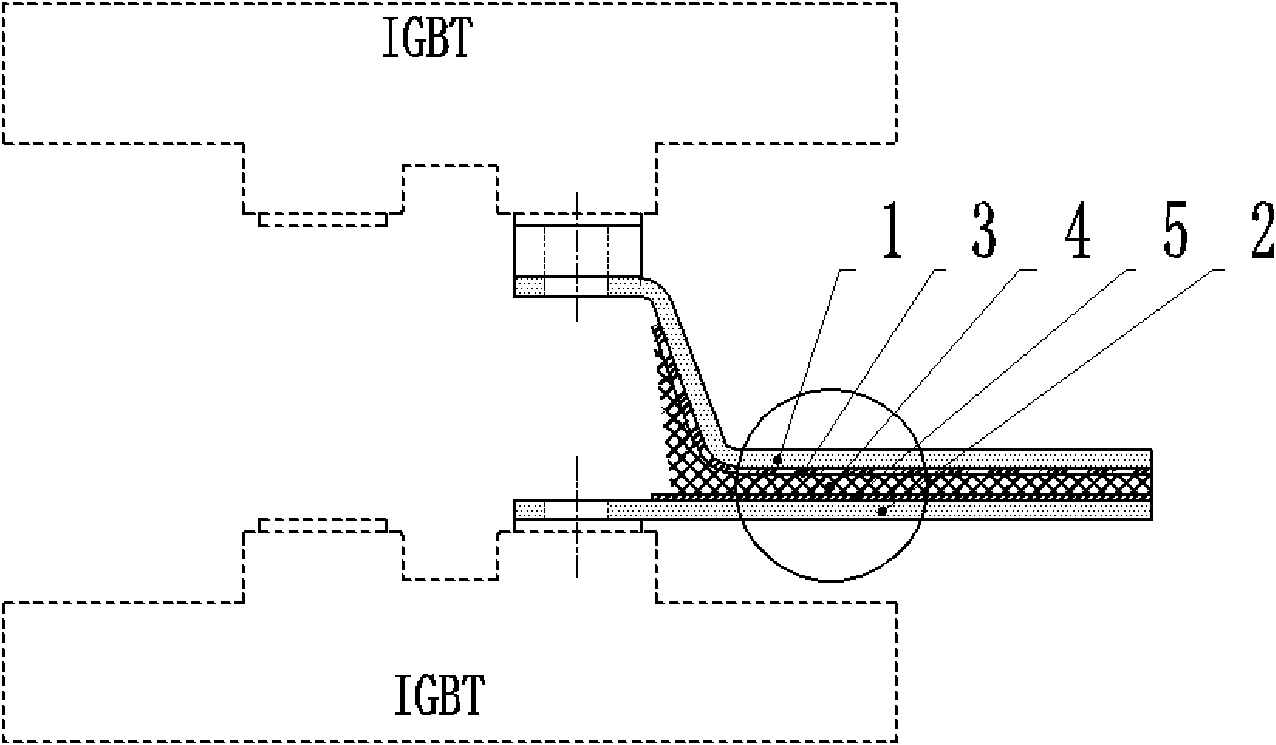

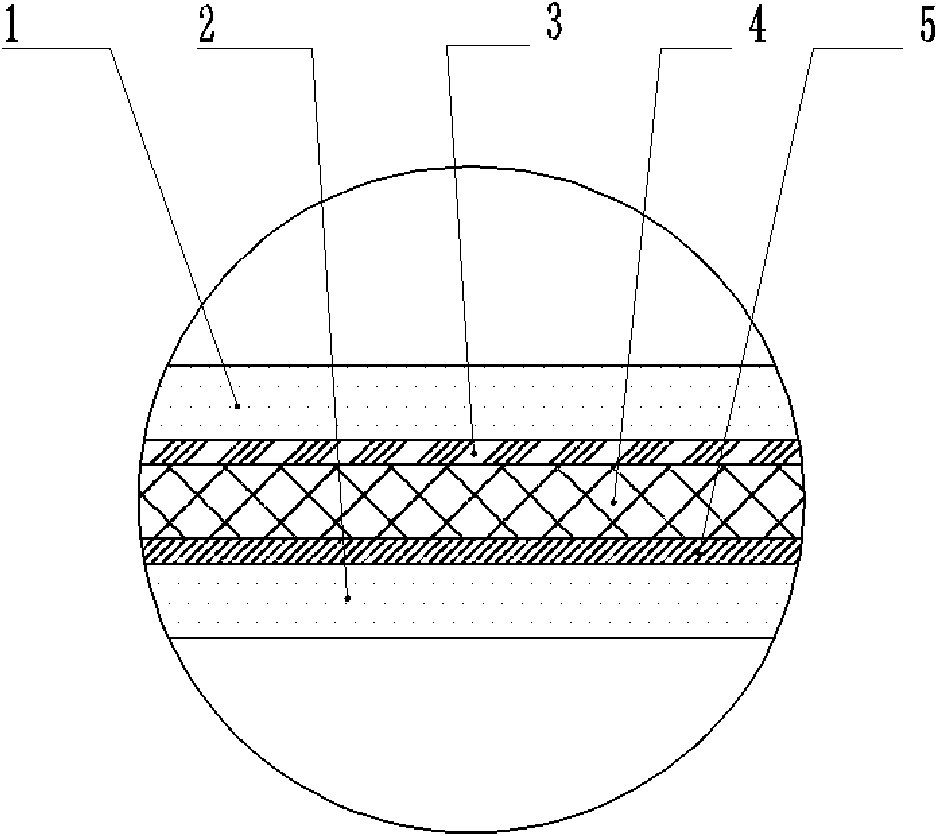

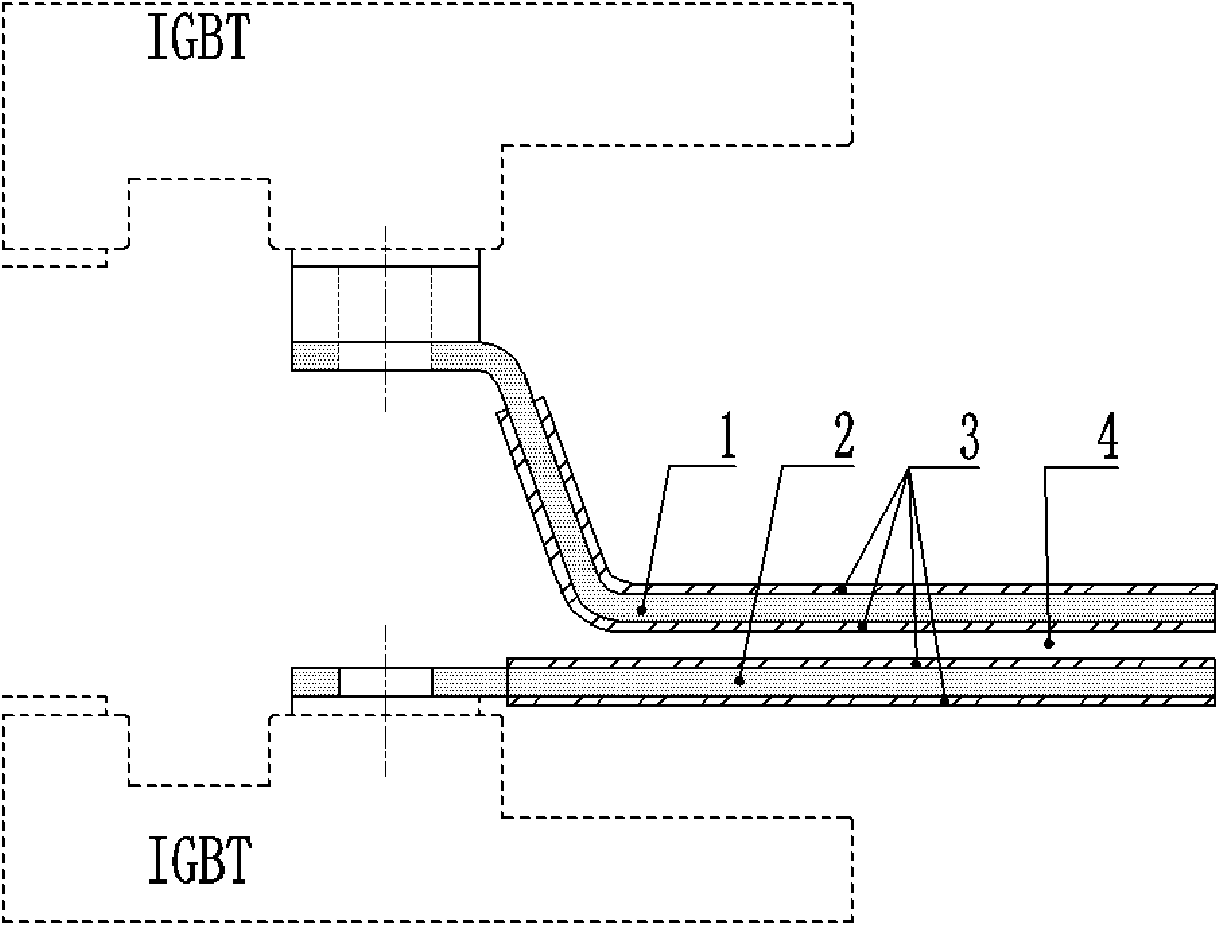

[0020] The low-inductance busbar based on composite insulation in this embodiment, such as Figure 1-3 Including copper row 1, copper row 2, insulating layer 3, insulating layer 4 and insulating layer 5 formed by orderly stacked multi-layer structure, wherein the orderly stacked arrangement is the outermost of the low-sensitivity bus bar is copper bar 1 and copper bar 2. The insulating layer 3, the insulating layer 4 and the insulating layer 5 are arranged in sequence among them.

[0021] The material of insulating layer 3, insulating layer 4 and insulating layer 5 is a combination of gas and solid insulating materials.

[0022] The insulating layer 4 is made of self-healing insulating material to prolong the service life of the busbar.

[0023] The copper bar 1 and the copper bar 2 are connected to the terminals of the power electronic device by means of bolt fastening, and the contact surface between the copper bar and the connecting terminal is nickel-plated to reduce the ...

Embodiment 2

[0027] The low-sensitivity busbar based on composite insulation in this embodiment includes a multi-layer structure formed by orderly stacking and arrangement of copper bar 1, copper bar 2, insulating layer 3, insulating layer 4 and insulating layer 5, wherein orderly stacking The outermost sides of the low-sensitivity busbars are arranged as copper bars 1 and 2, and insulating layers 3, 4, and 5 are arranged in sequence between them.

[0028] The material of the insulating layer 3, the insulating layer 4 and the insulating layer 5 is a solid insulating material.

[0029] The material of the insulating layer 4 is an insulating material with long-term corona resistance, so as to weaken the partial discharge phenomenon of the busbar.

[0030] The copper bar 1 and the copper bar 2 are connected to the terminals of the power electronic device by bolt fastening, and the connecting terminals are treated with silver plating to reduce the contact resistance.

[0031] The copper bar 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com