Hydrotreating method of inferior gasoline raw material

A low-quality gasoline and hydrotreating technology, which is applied in hydrotreating process, hydrocarbon oil treatment, petroleum industry, etc., can solve the problem that the device cannot be operated for a long period, avoid fouling and coking, avoid local overheating, and be easy to operate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

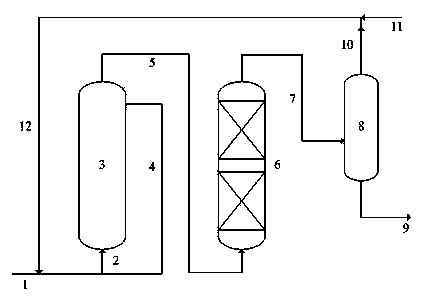

[0037] use figure 1 The process flow shown. The properties of the catalyst used are listed in Table 3, and the process conditions and test results are listed in Table 4 and Table 11, respectively.

[0038] Table 3 The main composition and properties of the catalysts.

[0039] pretreatment catalyst hydrogenation catalyst Catalyst composition MoO 3 +CoO / wt% 5 20 carrier Aluminum oxide Aluminum oxide The main properties of the catalyst Particle size, mm 0.2 — Specific surface / m 2 g -1 180 226 Pore volume / mL·g -1 0.68 0.51

[0040] Table 4 Example 1 process conditions.

[0041] Process conditions data volumetric space velocity, h -1 4 Cycle oil / raw material weight ratio 0.50 Hydrogen / coked gasoline volume ratio 300 Average reaction temperature of pretreatment reactor / °C 230 Average reaction temperature of hydrotreating reactor / °C 290 Reaction press...

Embodiment 2

[0043] use figure 1 The process flow shown. The catalyst properties used are listed in Table 5, and the process conditions and test results are listed in Table 6 and Table 11 respectively.

[0044] Table 5 Main composition and properties of catalysts.

[0045] pretreatment catalyst hydrogenation catalyst Catalyst composition MoO 3 +CoO / wt% 0 25 carrier Aluminum oxide Aluminum oxide The main properties of the catalyst Particle size, mm 0.3 — Specific surface / m 2 g -1 180 226 Pore volume / mL·g -1 0.68 0.51

[0046] Table 6 Example 2 process conditions.

[0047] Process conditions data volumetric space velocity, h -1 4 Heat load oil / raw material weight ratio 0.60 Hydrogen / coked gasoline volume ratio 300 Average reaction temperature of pretreatment reactor / °C 230 Average reaction temperature of hydrotreating reactor / °C 290 Reaction pressure / MPa 2.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com