Overheating preventing structure for super-large current lead of transformer

A technology of current lead and transformer, applied in the field of transformer manufacturing, can solve the problems of lead wire overheating and overheating, and achieve the effect of simple structure and good manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

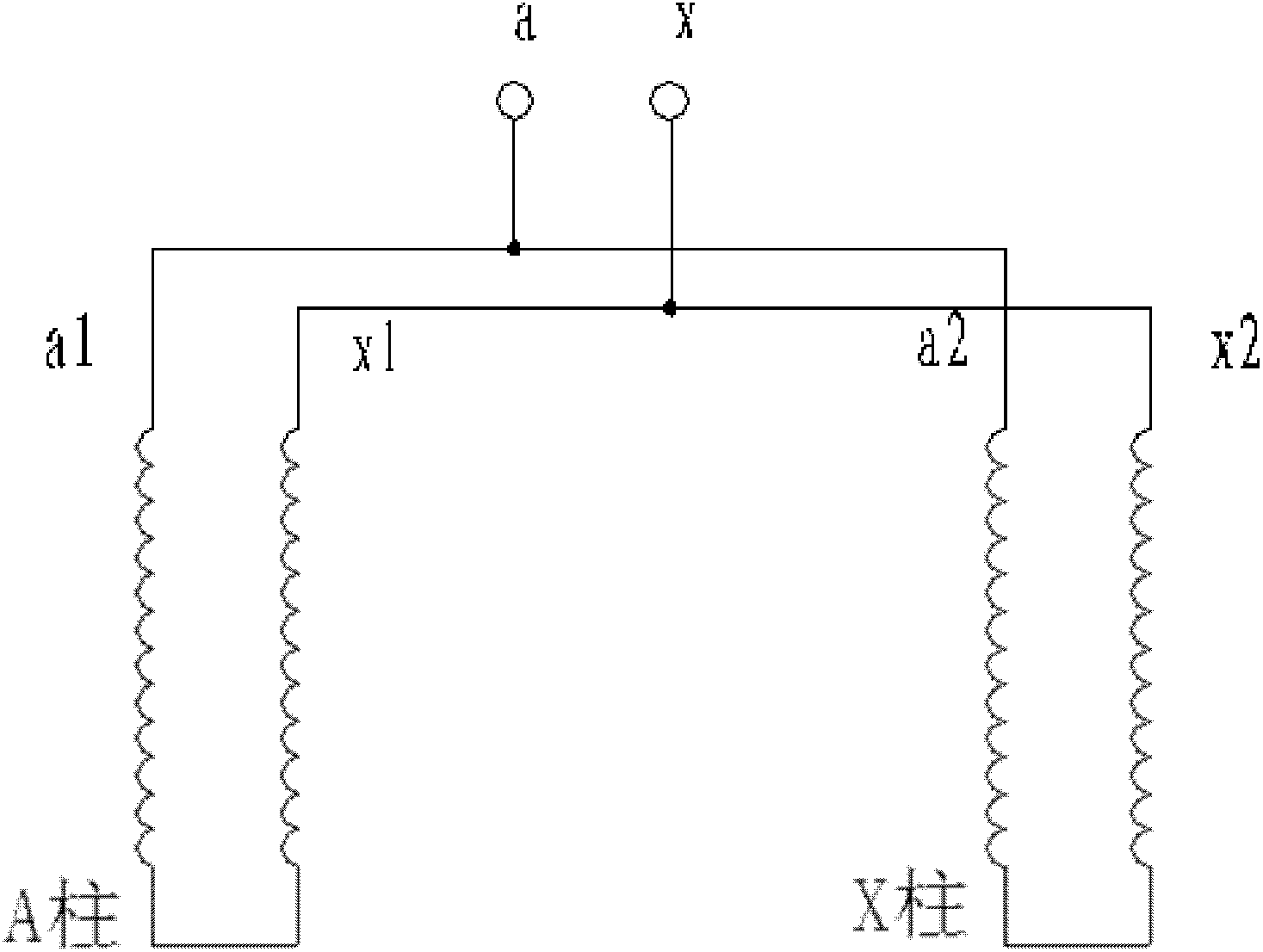

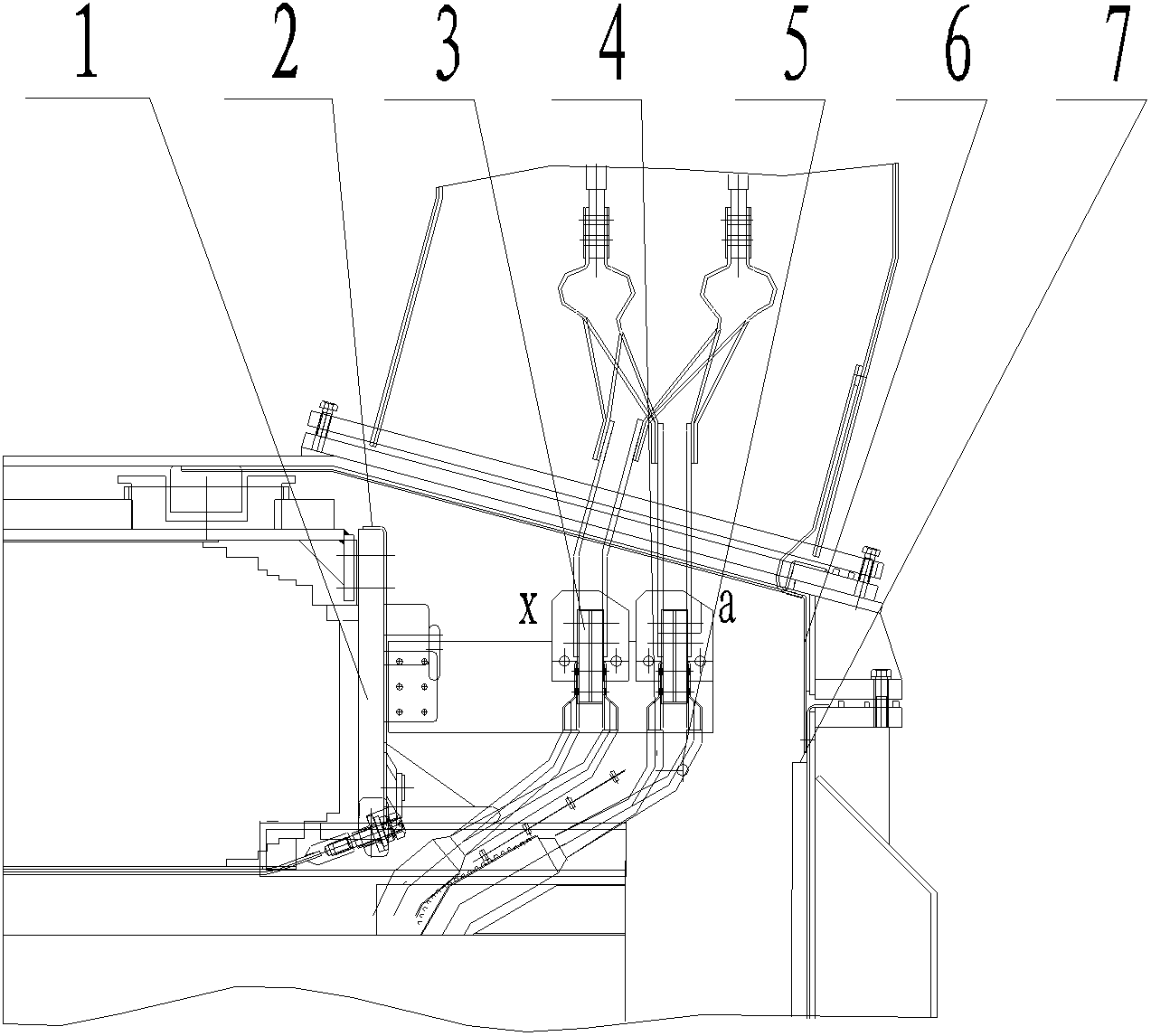

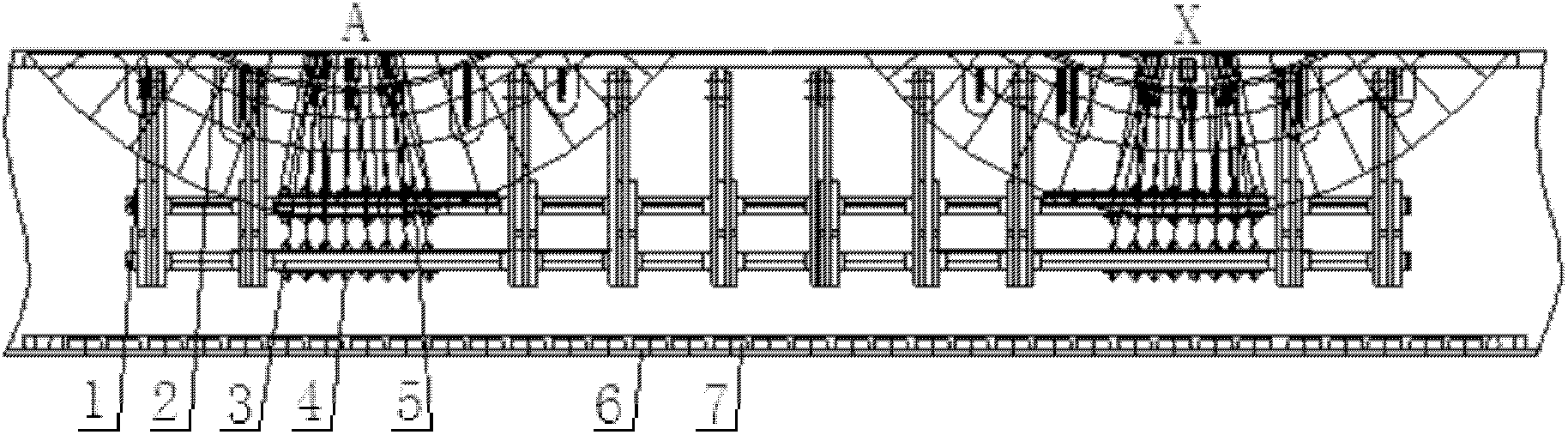

[0016] The invention discloses an overheating prevention structure for super large current lead wires of a transformer, which is arranged on the low voltage side of the transformer, and adopts a shielding method combining magnetic shielding and copper shielding around the high current lead wires on the low voltage side.

[0017] The clamp copper shield 2 is provided on the upper iron core clamp 1 of the low-voltage side, and the fuel tank copper shield 6 is provided on the inner surface of the low-voltage side tank cover and the low-voltage tank wall. At the same time, a vertical fuel tank magnetic shield 7 is installed on the low-voltage tank wall through the magnetic shield The eddy current diamagnetic field generated by the high magnetic permeability of the copper shield and the high conductivity of the copper shield reduces the magnetic flux of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com