Fractal micro-channel cold plate with bidirectional flow path

A two-way flow, micro-channel technology, applied in the direction of cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc., can solve the problem of uneven temperature of the cold plate in the unidirectional flow path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

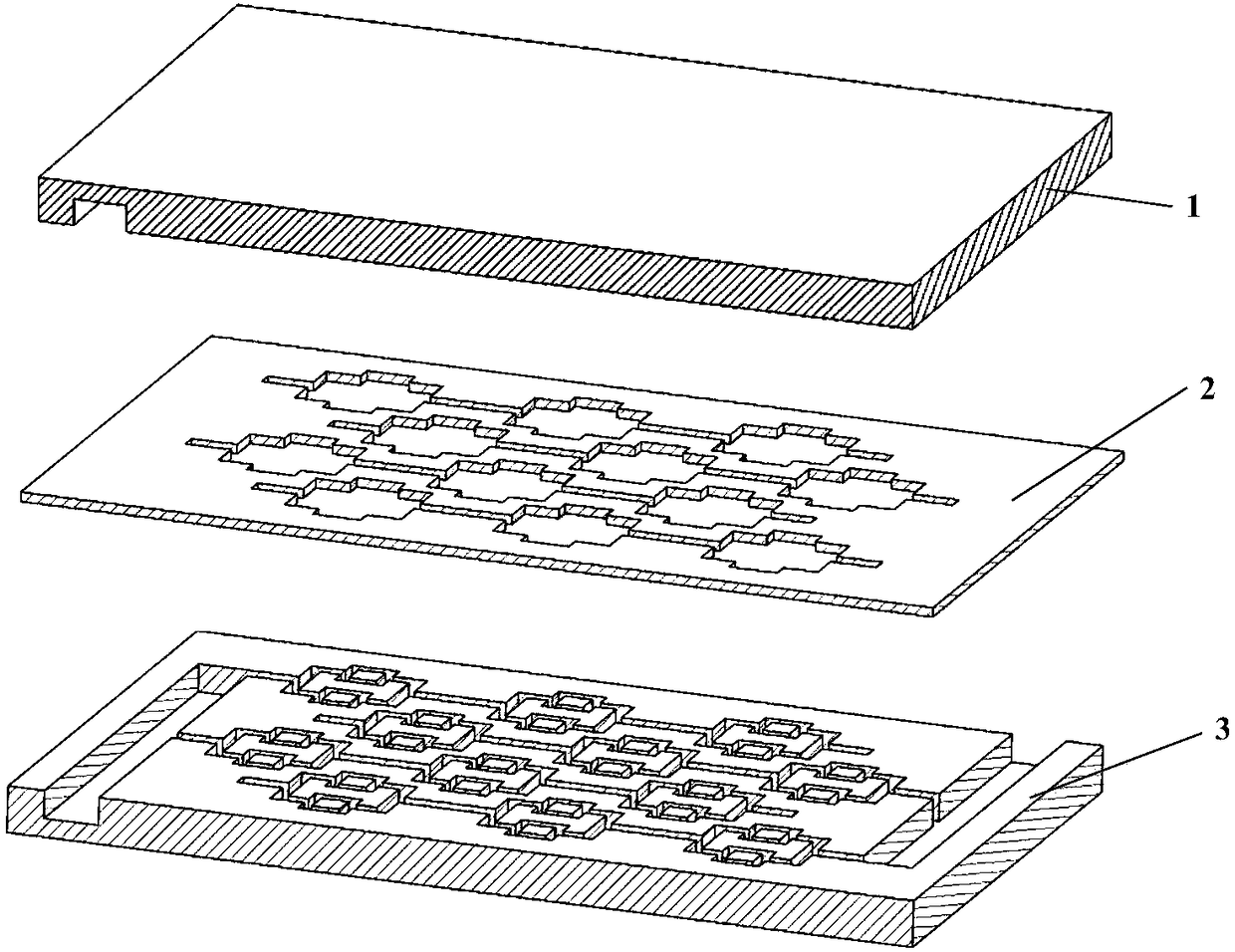

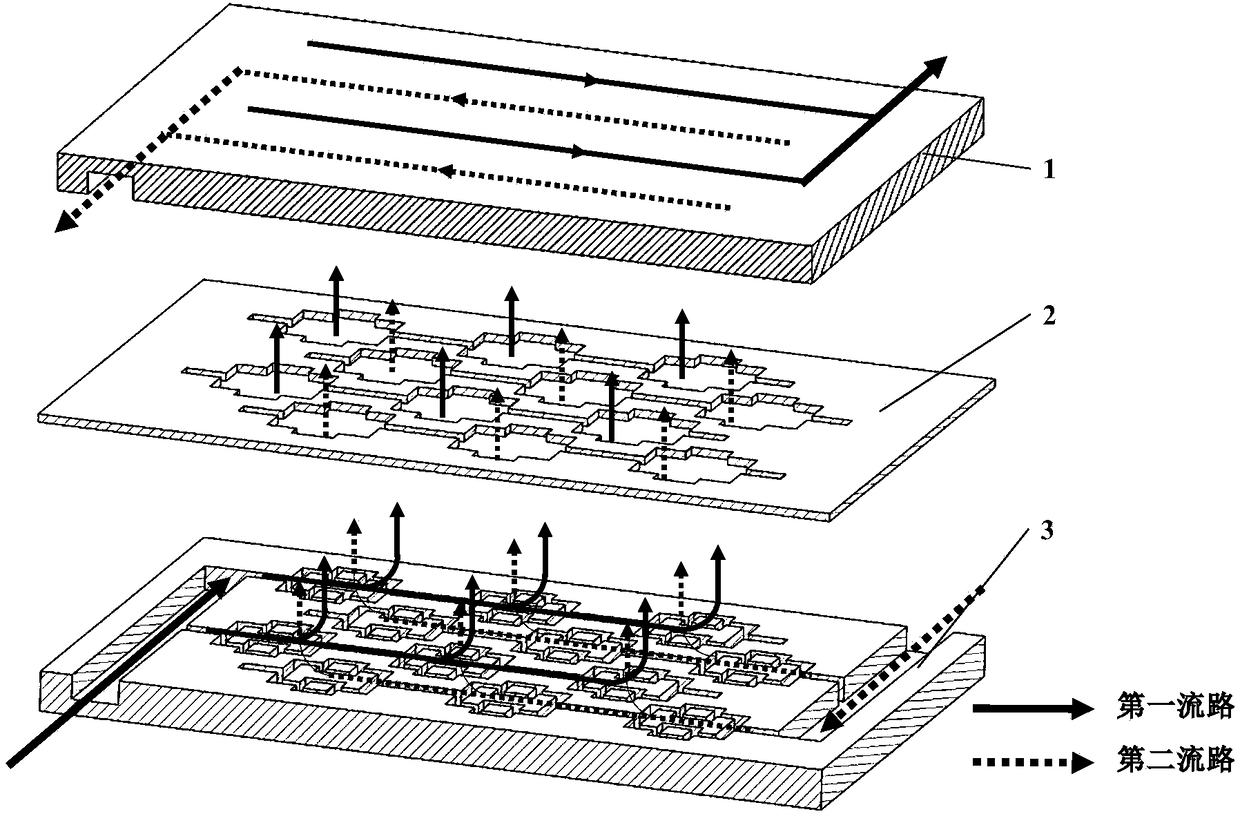

[0029] Such as figure 1 As shown, a preferred embodiment of the present invention provides a fractal micro-channel cold plate with two-way flow paths, including a liquid inlet plate 1 , a middle plate 2 and a liquid return plate 3 . in,

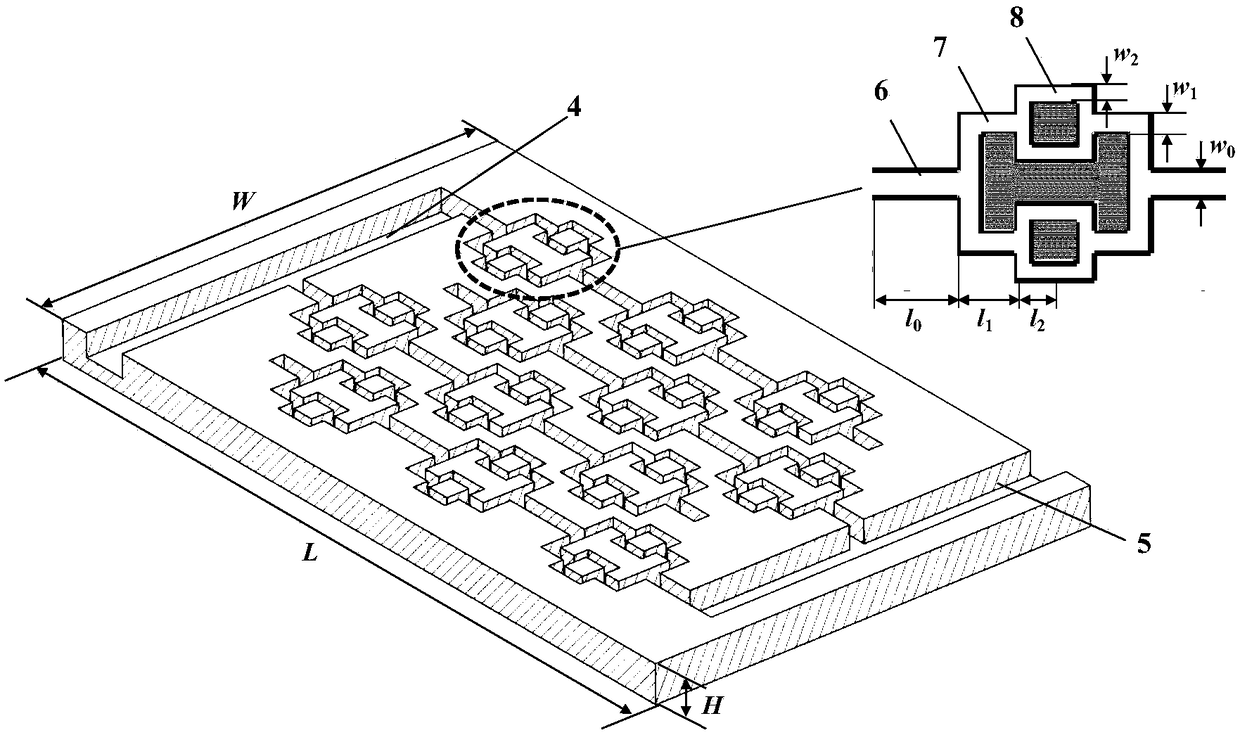

[0030] Such as image 3 As shown, the liquid inlet plate includes the first inlet liquid separation channel 4, the second inlet liquid separation channel 5 and the liquid inlet zero-level branch channel, the first inlet liquid separation channel 4 and the odd-numbered rows of liquid inlet zero-level channels The branch channels are connected, and the second inlet liquid separation channel 5 is connected with the zero-level branch channels of the even-numbered rows of liquid inlet;

[0031] Such as Figure 4 As shown, the middle plate 2 includes a hollow hole 9, and the hollow hole 9 is set to correspond to the liquid inlet zero-order branch channel; the length and width of the middle plate 2 are consistent with the liquid inlet plate 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com