Application of continuous microwave reactor

A reaction equipment and microwave technology are applied in the field of preparing ionic liquids and microwave continuous reaction equipment, which can solve the problems of inability to produce ionic liquids in large-scale industrial production, difficult to guarantee product purity, and high solubility of methylimidazole, and achieve simple structure and save operation. Steps, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

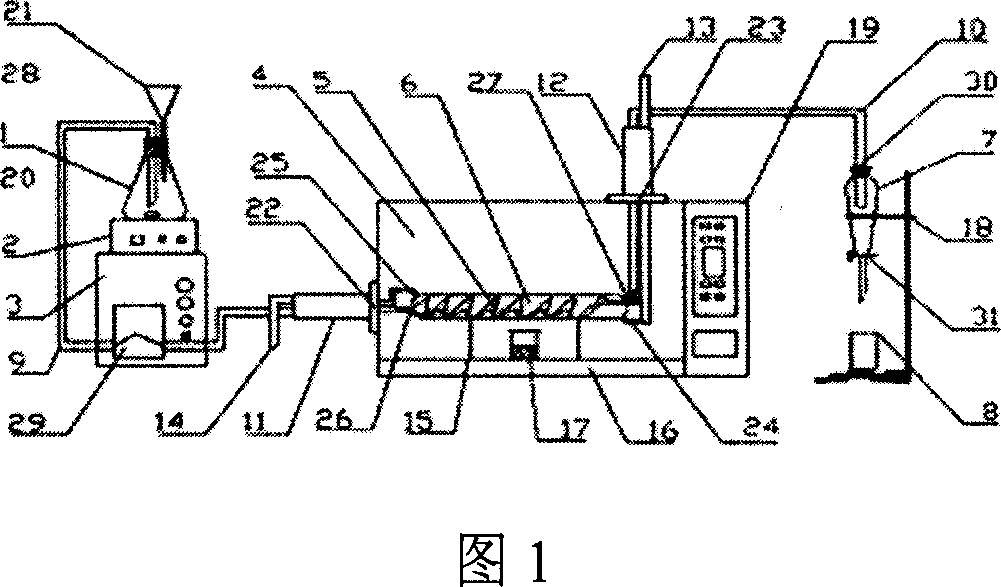

[0054] Example 1 New microwave continuous reaction equipment

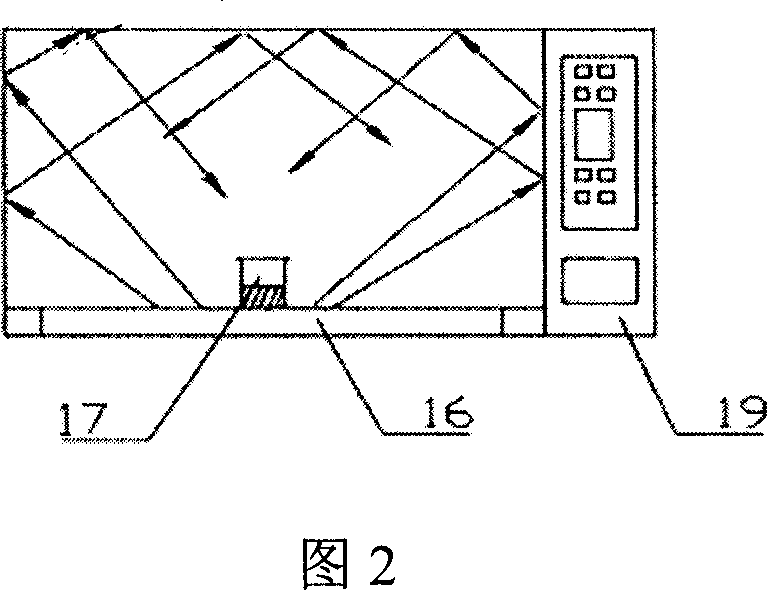

[0055] A novel microwave continuous reaction equipment of the present invention, as shown in Fig. Separation device 7, product collection device 8, feed pipe 9, discharge pipe 10, side pipe 11, top pipe 12, condensate inflow pipe 13, condensate outflow pipe 14, reactor bracket 15, microwave emission source 16, Glass container 17, iron stand 18, microwave oven 19, stirrer 20, feed funnel 21, side hole 22, top hole 23, condensate outflow interface 24, condensate inflow interface 25, feed interface 26, material discharge interface 27, Rubber plug I 28, pump head 29, rubber plug II 30 and material prevention valve 31.

[0056] The microwave oven 19 of the present invention is Haier's new type converter MF-2070EGZ; the microwave cavity cavity 4 is the microwave cavity cavity of the microwave oven 19; the microwave emission source 16 is welded on the bottom of the microwave cavity cavity 4, and a microwave emission sour...

Embodiment 2

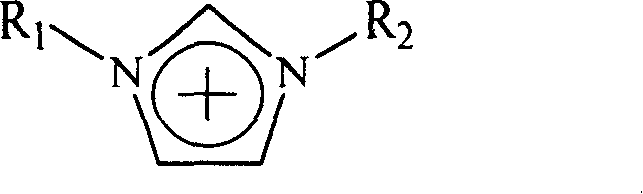

[0064] Example 2 Preparation of ionic liquid 1-hexyl-3-methylimidazolium bromide with microwave continuous reaction equipment of the present invention

[0065] Take 79ml (1mol) of 1-methylimidazole and 139ml (1mol) of 1-bromohexane and mix them, flow them into a 250ml three-necked bottle through the feeding funnel, stir evenly, and flow into the reactor through the feeding pipe under the drive of the constant flow pump Medium (microwave power is 280W). Adjust the flow rate of the magnetic stirrer to make it stir evenly, adjust the flow rate of the constant flow pump (adjust the value of the constant flow pump to 1.0, and the flow rate is 1.86ml.s -1 ), the flow time of the reaction materials in the reactor is 2.5 minutes, and water is passed into the cooling device for heat exchange to achieve a controlled reaction temperature of 60-65°C. Driven by the constant flow pump, the reactant material flows into the separatory funnel from the reactor through the discharge pipe, and t...

Embodiment 3

[0072] Example 3 Preparation of ionic liquid ionic liquid 1-octyl-3-methylimidazolium chloride salt with microwave continuous reaction equipment of the present invention

[0073] Take 79ml (1mol) of 1-methylimidazole and 170ml (1mol) of 1-chlorooctane and mix them, flow them into a 250ml three-neck bottle through the feeding funnel, stir evenly, and flow into the reactor through the feeding pipe under the drive of the constant flow pump Medium (microwave power is 420W). Adjust the flow rate of the magnetic stirrer to make it stir evenly, adjust the flow rate of the constant flow pump (adjust the value of the constant flow pump to 0.5, and the flow rate is 0.67ml.s -1 ), the flow time of the reaction materials in the reactor is 3 minutes, and water is passed into the cooling device for heat exchange to achieve a controlled reaction temperature of 65-70°C. Driven by the constant flow pump, the reactant material flows into the separatory funnel from the reactor through the disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com