High-calcium milk as well as raw material composition and preparation method thereof

A technology of raw material composition and calcium compound, which is applied in the directions of milk preparations, dairy products, applications, etc., can solve the problems of protein flocculation and scaling, poor product stability, etc., and achieve the effects of good absorption, good stability and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

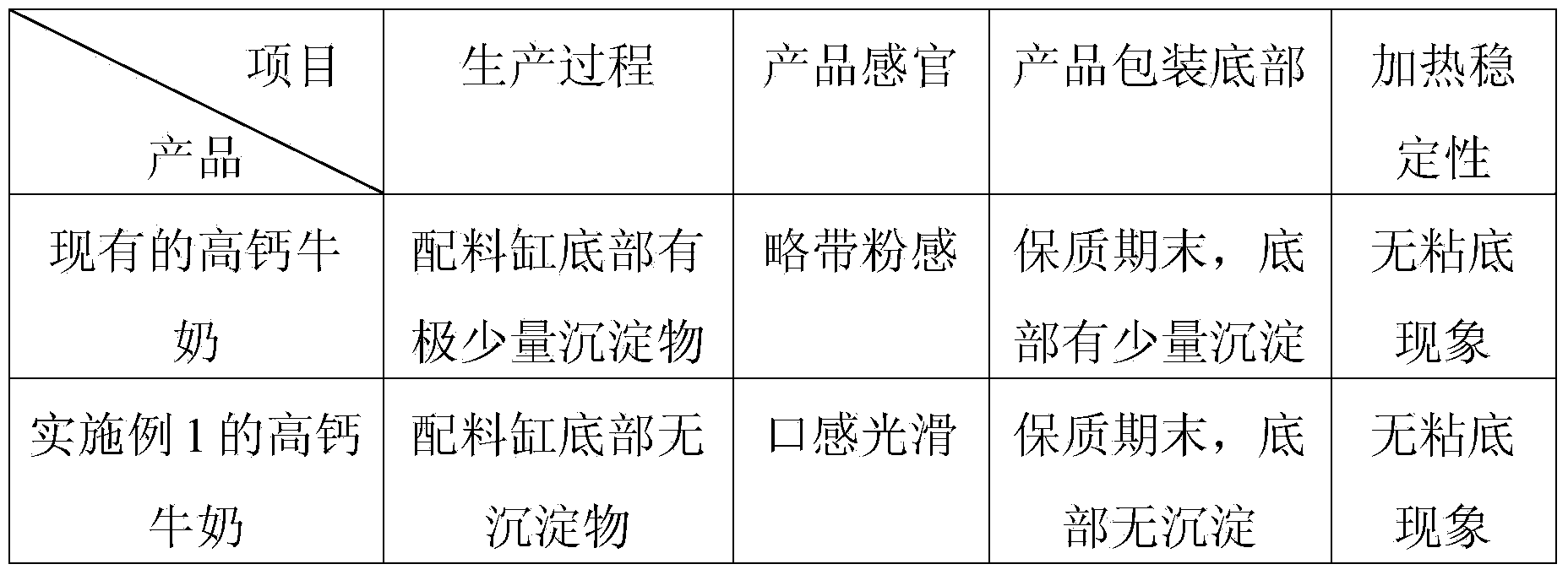

Examples

Embodiment 1

[0037] The raw material composition of the high calcium milk of this embodiment is shown in Table 1.

[0038] The raw material composition of the high calcium milk of table 1 embodiment 1

[0039] Element

Dosage (%)

milk

99.3

calcium lactate

0.45

[0040] Sodium citrate

0.1

sodium tripolyphosphate

0.05

Mono, Diglycerides of Fatty Acids

0.1

[0041] The preparation method of the high-calcium milk of the present embodiment comprises the following processing steps:

[0042] (1) Heat a certain amount of drinking water to 85°C, add the other ingredients in the above formula except milk, stir until fully dissolved, and cool down to 45°C;

[0043] (2) Heat the milk to 45°C, spray the solution obtained in step (1) and stir for 10 minutes;

[0044] (3) The flash evaporation method evaporates the water dissolved in the ingredients in step (1);

[0045] (4) Heat up to 65°C, homogenize at 20MPa, pa...

Embodiment 2

[0047] The raw material composition of the high-calcium milk of this embodiment is shown in Table 2.

[0048] The raw material composition of the high calcium milk of table 2 embodiment 2

[0049] Element

Dosage (%)

milk

99.58

L-Calcium Lactate

0.3

Sodium citrate

0.08

Mono, Diglycerides of Fatty Acids

0.04

[0050] The preparation method of the high-calcium milk of the present embodiment comprises the following processing steps:

[0051] (1) Heat a certain amount of drinking water to 80°C, add the other ingredients in the above formula except milk, stir until fully dissolved, and cool down to 50°C;

[0052] (2) Heat the milk to 50°C, spray the solution obtained in step (1) and stir for 15 minutes;

[0053] (3) The flash evaporation method evaporates the water dissolved in the ingredients in step (1);

[0054](4) Heat up to 75°C, homogenize at 18MPa, pasteurize at 75°C for 15s, cool to 2°C to 6°C, and fill. ...

Embodiment 3

[0056] The raw material composition of the high calcium milk of this embodiment is shown in Table 3.

[0057] The raw material composition of the high calcium milk of table 3 embodiment 3

[0058] Element

Dosage (%)

milk

99.44

calcium lactate

0.4

Sodium citrate

0.08

potassium citrate

0.04

Mono, Diglycerides of Fatty Acids

0.02

Sucrose Fatty Acid Ester

0.02

[0059] The preparation method of the high-calcium milk of the present embodiment comprises the following processing steps:

[0060] (1) Heat a certain amount of drinking water to 80°C, add the other ingredients in the above formula except milk, stir until fully dissolved, and cool down to 50°C;

[0061] (2) Heat the milk to 50°C, spray the solution obtained in step (1) and stir for 10 minutes;

[0062] (3) Falling film concentration method removes the moisture of dissolved ingredients in step (1);

[0063] (4) Heat up to 75°C, homog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com