Internal thread pipe for improving anti-scaling performance of valve and design optimization method

An internally threaded pipe, anti-scaling technology, applied in design optimization/simulation, instrumentation, electrical digital data processing, etc., can solve problems such as difficulty in judging cleaning effect, insufficient scaling and cleaning, shortening valve service life, etc. The effect of improving the scaling phenomenon, improving the anti-scaling performance and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

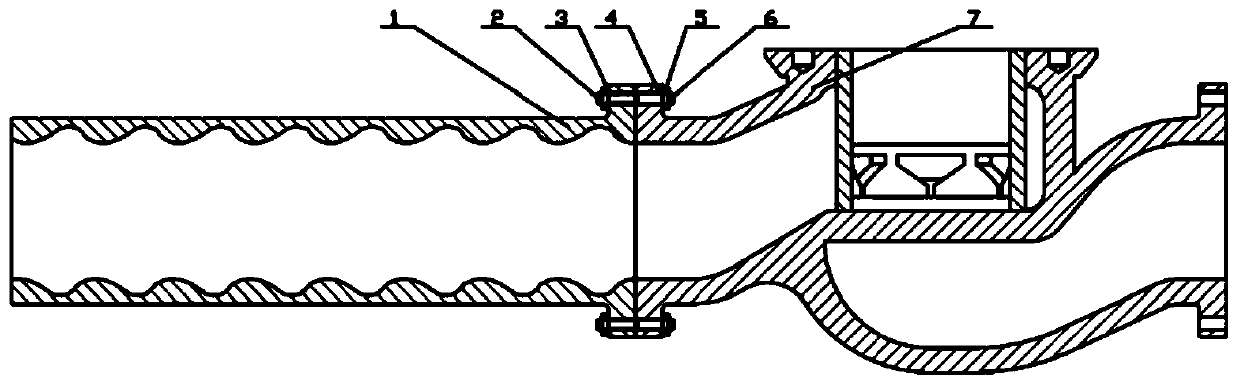

[0060] Use the above method to design the corresponding internal thread pipe for the valve with working pressure PN=1.6MPa, working temperature at 20°C and diameter DN=20mm, particle diameter d p =5×10 -5 m, particle density ρ p =2600kg / m 3 ,Specific steps are as follows:

[0061] (1) The diameter of the valve is DN=20mm, then the outer diameter of the internally threaded pipe is 26.7mm, the wall thickness is 1mm, and the inner diameter D of the pipe is 24.7mm;

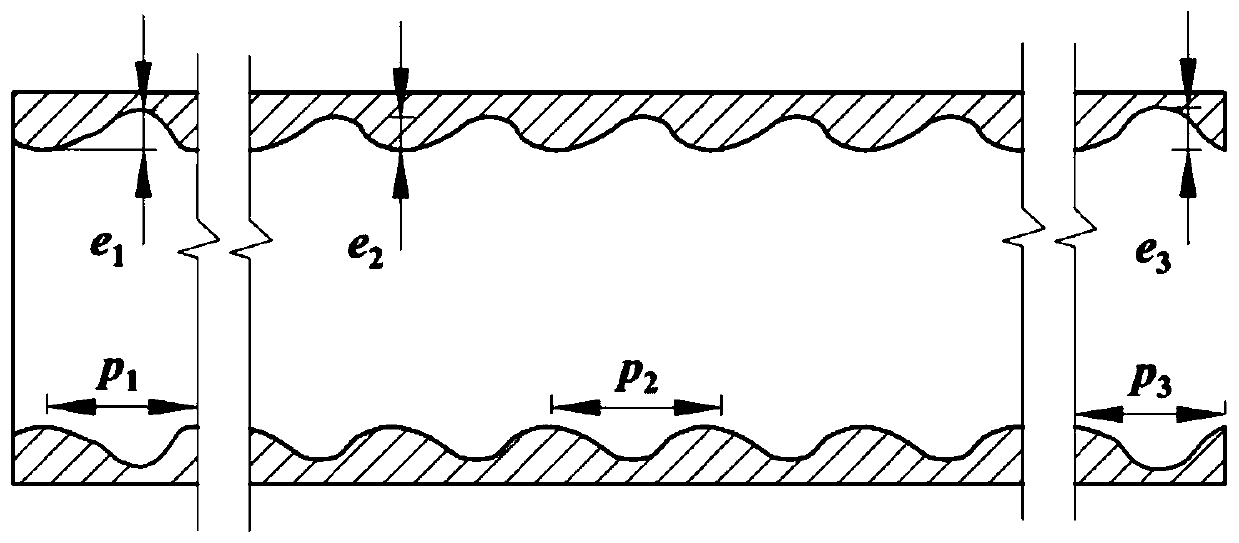

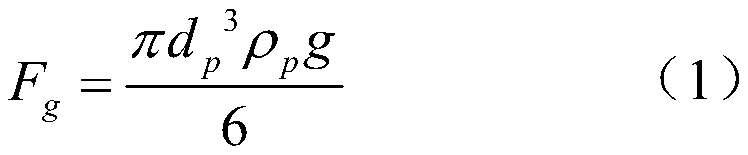

[0062] (2) To analyze the stress of solid particles, the gravity, fluid force, and centrifugal force generated by spiral motion are mainly considered. The calculation formulas are shown in the aforementioned formulas (1) to (3).

[0063] (3) Design the entrance strengthening section of the internally threaded pipe, considering the influence of the entrance effect, and at the same time change the shape of the thread so that more solid particles can be deposited on the pipe wall, increasing the pitch can increase the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com