Adjustable throttling device

A throttling device and adjustable technology, applied in the direction of pipes/pipe joints/fittings, mechanical equipment, pipe components, etc., can solve problems such as structural changes, unstable outflow coefficients, and impurity deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

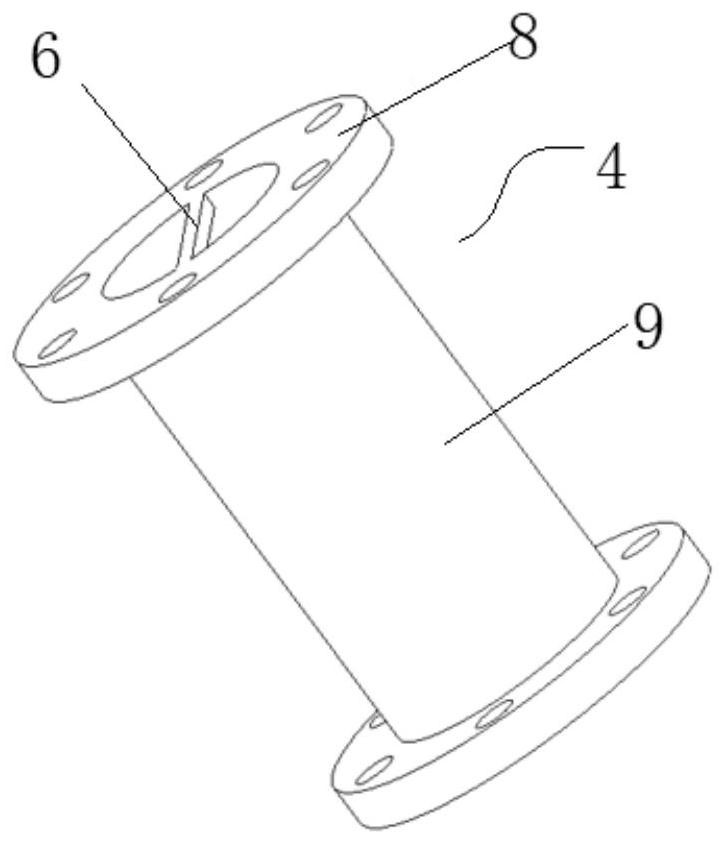

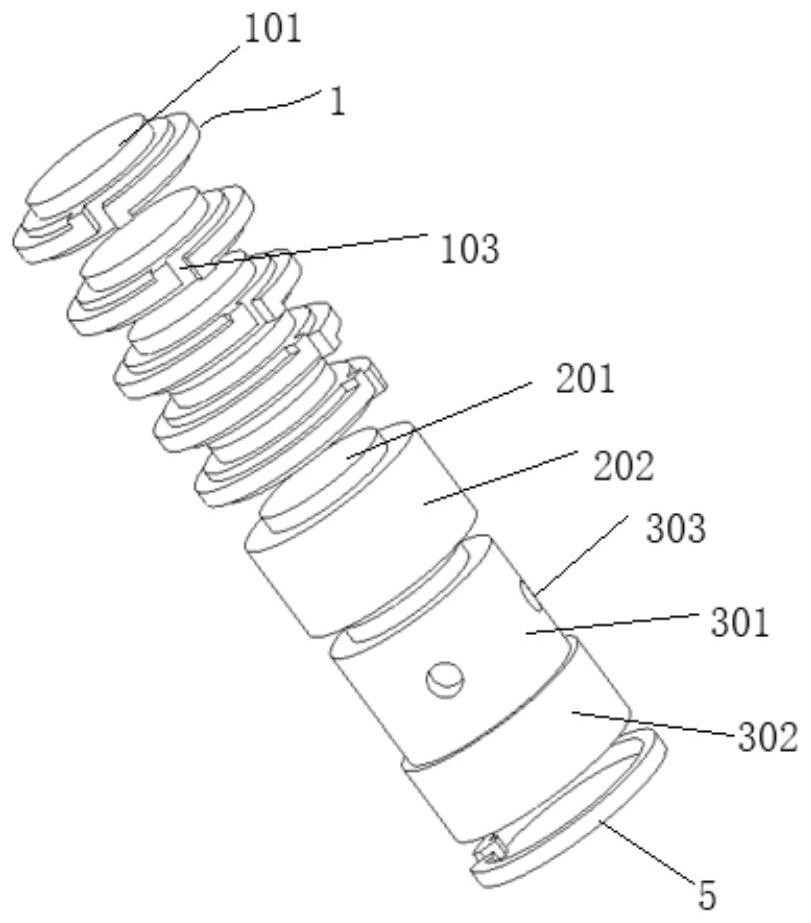

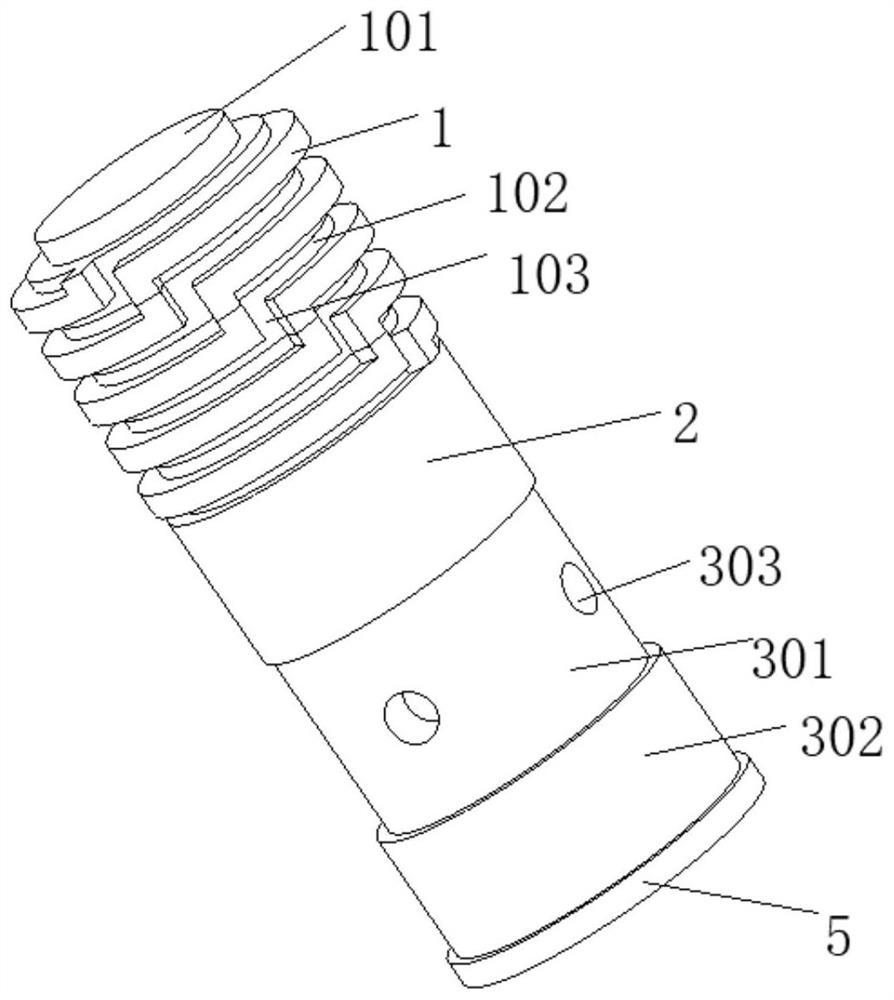

[0033] figure 1 It is a structural schematic diagram of the outer casing of the present invention, diagram 2-1 For the exploded view of other constructions after removing the outer casing of the present invention, Figure 2-2 for diagram 2-1 Schematic diagram of the structure after assembly, Figure 2-3 for diagram 2-1 longitudinal sectional view of Figure 2-4 for Figure 2-2 longitudinal sectional view of image 3 It is a structural schematic diagram of the fluid flow direction of the present invention. As shown in the above figure: the adjustable throttling device provided by the present invention, the adjustable throttling device includes: an outer sleeve 4, a number of first inner stems 1, a second inner stem 2, a third inner stem Stem 3, a limit snap ring 5, a limit rib ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com