Multi-layer and multi-medium sedimentation type industrial water filtering system

A filtration system, sedimentation technology, applied in the direction of filtration separation, gravity filter, loose filter material filter, etc., can solve the problems of large industrial water consumption, waste, environmental pollution, etc., and achieve the effect of reducing turbidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

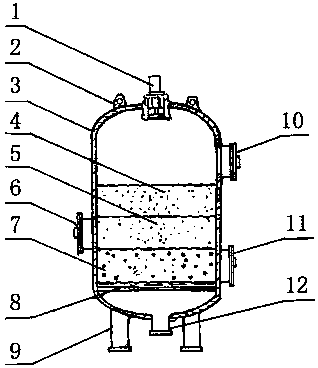

[0011] attached by figure 1 As shown, the multi-layer multi-media sedimentation industrial water filtration system consists of liquid inlet pipe 1, tank ear 2, tank body 3, quartz sand filter layer 4, anthracite filter layer 5, anthracite cleaning port cover 6, activated carbon filter layer 7, net Shaped partition 8, tank leg 9, upper cleaning cover 10, activated carbon cleaning cover 11, and liquid outlet pipe 12; the upper center of the tank body 3 is provided with a liquid inlet pipe 1, and both sides are provided with tank ears 2, and one side of the tank body 3 The middle part is provided with anthracite cleaning port cover 6, the upper part of the other side is provided with upper cleaning port cover 10, the bottom part is provided with activated carbon cleaning port cover 11, tank leg 9 is provided around the bottom of tank body 3, and liquid outlet pipe 12 is provided at the center.

[0012] Quartz sand filter layer 4 , anthracite filter layer 5 and activated carbon fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com