Flexible composite pipe underground laying method capable of quickly collecting pipes without excavating

A flexible composite pipe, non-excavation technology, applied in the direction of pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of pipeline damage, difficult excavation, low safety, etc., and achieve protection traction damage, reduce construction costs, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

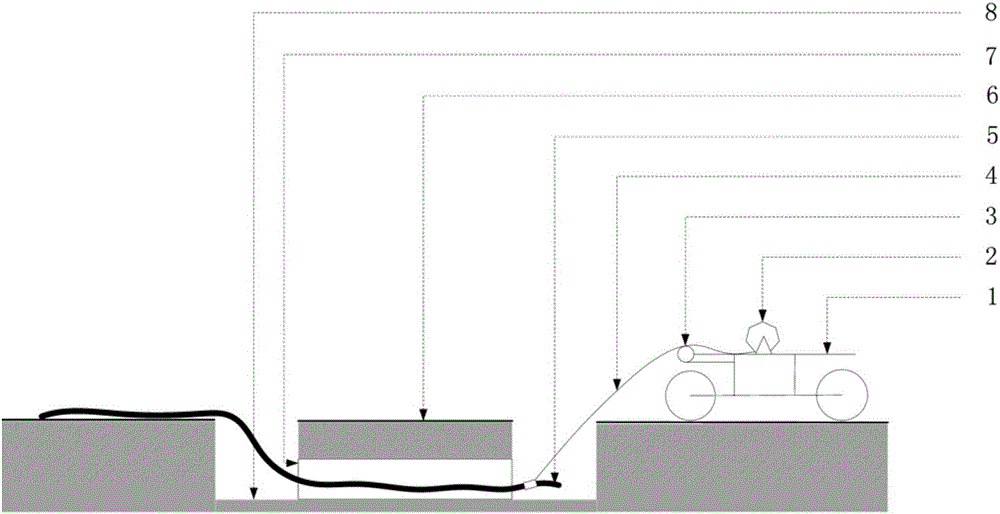

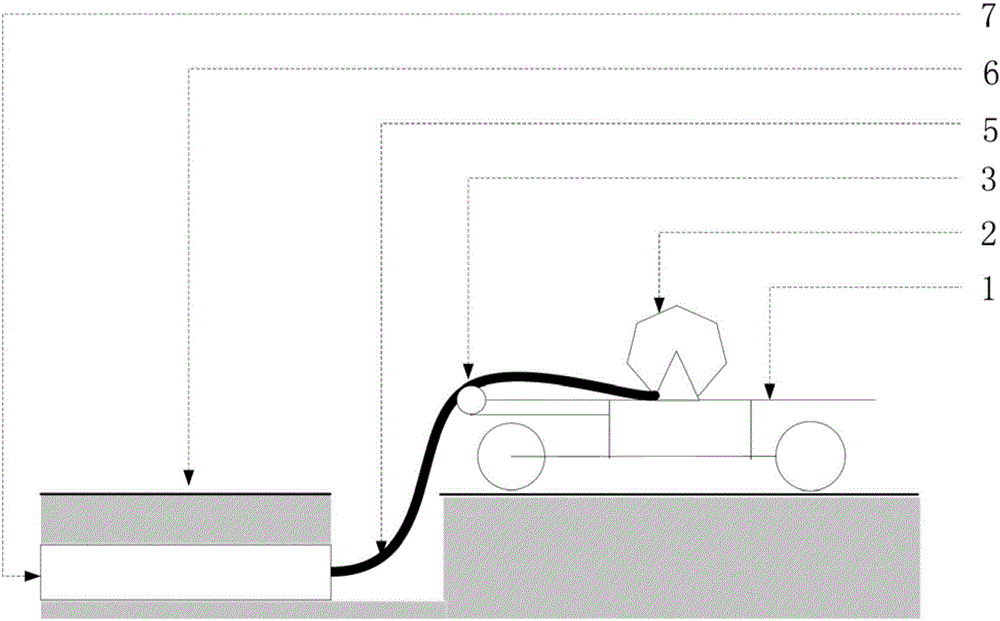

[0028] Example 1: Aramid fiber reinforced heat-resistant polyethylene plastic (PE-RT) flexible composite pipe (specification DN100PN4MPa) laying and pipe taking construction 2km

[0029] 1) Pipe trench excavation: Use a trencher to excavate the pipe trench with a set depth of 1.5 meters and a width of 0.5 meters. The length of the first section of the pipe trench is the length of a single flexible composite pipe to be laid, that is, 500m. The initial position and the end position of laying a single flexible composite pipe are 8+1 excavated. The distance between two adjacent operation pits 8 is the length of each flexible composite pipe, that is, 500m. The size of the foundation pit is 2m×2m, and the depth is the same as that of the ditch;

[0030] 2) Outer casing installation and inner threading guide line: Pre-embed the outer casing 7 in the excavated ditch, and use PVC corrugated pipe 7 (nominal diameter DN300, ring stiffness level S2) for manual socket connection installati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com