Annular inlet blade of SDA desulfurization column

An imported blade, desulfurization tower technology, applied in gas treatment, dispersed particle separation, membrane technology, etc., can solve the problems of easy scaling, affecting the airflow distribution in the tower, reducing the chemical reaction rate and desulfurization efficiency, etc. fouling, sufficient reaction, and the effect of changing the flue gas flow field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

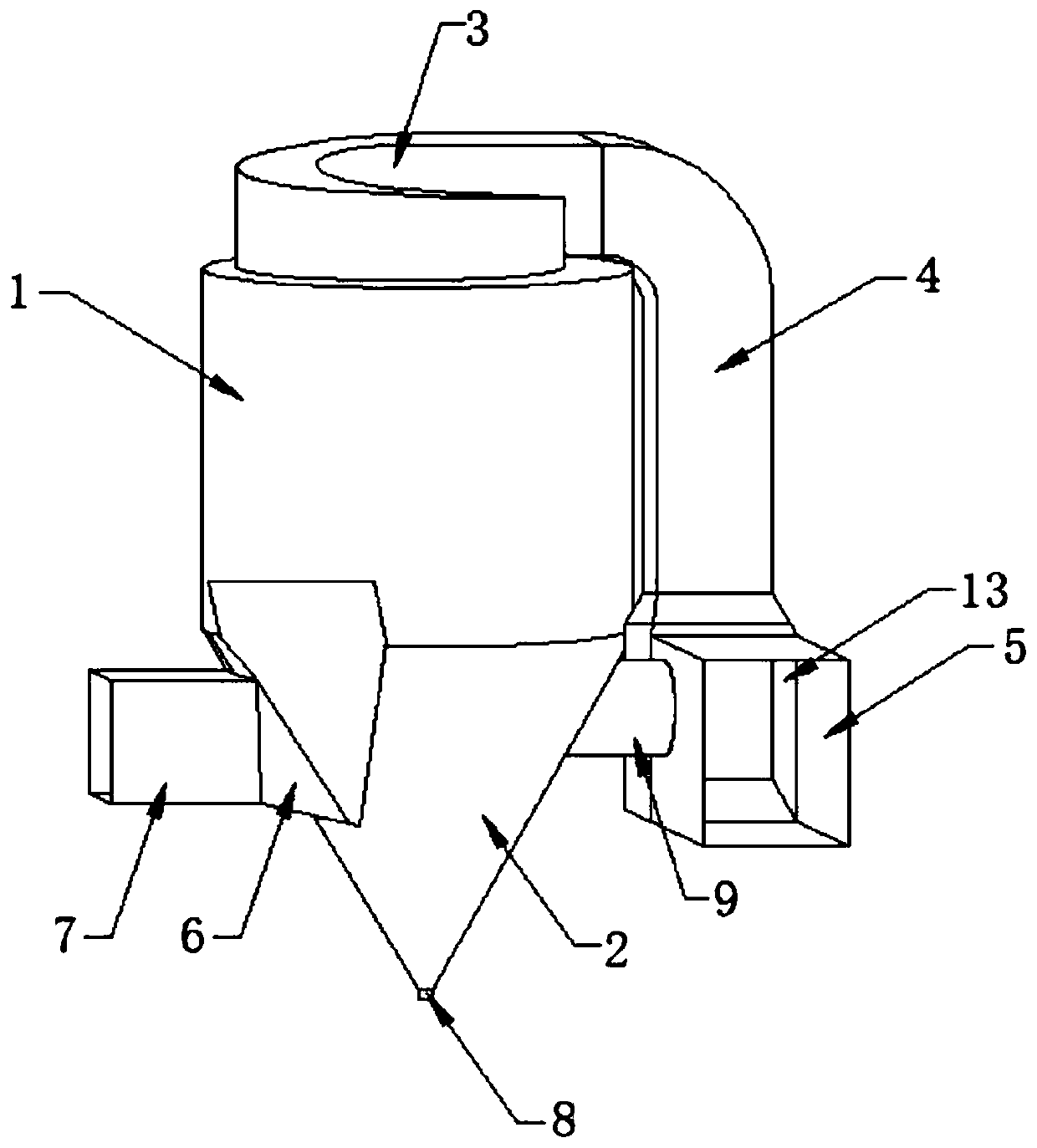

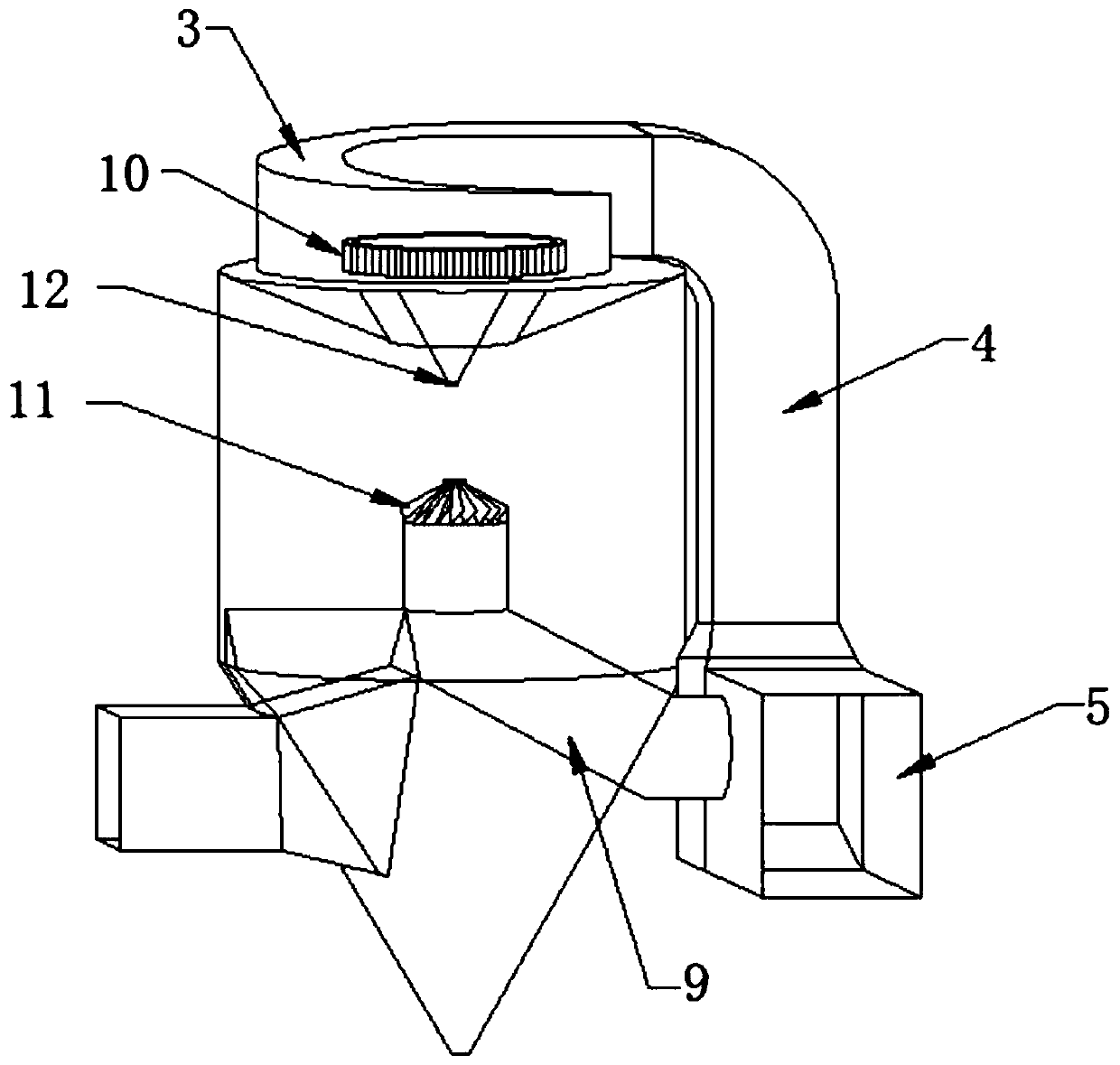

[0021] Such as Figure 1-2 As shown, the present invention provides an annular inlet vane of a SDA desulfurization tower, comprising a desulfurization tower main body 1, an air inlet pipe 3 is arranged on the top of the desulfurization tower main body 1, and an air inlet blade 10 is installed inside the air inlet pipe 3, and the air inlet blade 10 The bottom is in the shape of a conical funnel. The total number of air inlet blades 10 is 120 blades. A flue gas distributor 11 is installed at the bottom of the desulfurization tower main body 1, and a conical tower 2 is arranged at the bottom of the main body 1 of the desulfurization tower.

[0022] The height of each blade of the air inlet blade 10 is 2 meters, the width of the front is 40 cm, and the width of the folding part is 40 cm. airflow field.

[0023] The outer side of the conical tower 2 is provided with a mounting frame 6 , and one side of the mounting frame 6 is provided with a flue gas outlet 7 , through which the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com