Degradable polymer as well as preparation method and application thereof

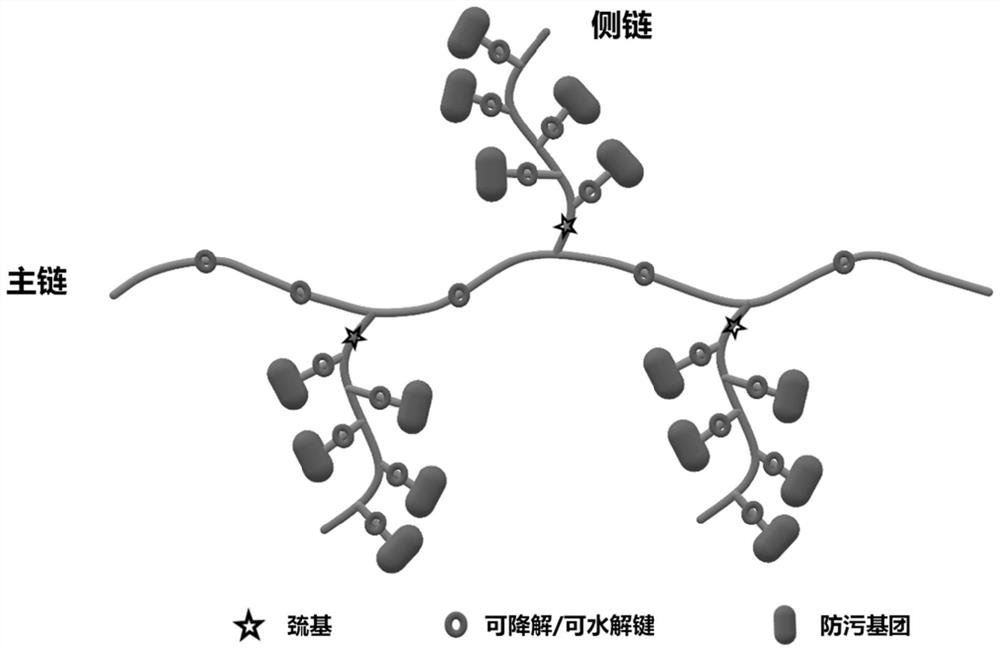

A technology for degrading polymers and polymers, applied in the field of materials, can solve the problems of low content of antifouling groups, inability to achieve long-term effect and controllable release of antifouling groups, etc., and achieve excellent antibacterial effect and excellent prevention and control of water fouling. effect, the effect of realizing industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] The raw materials for the preparation of the degradable polymer in this example are shown in Table 1.

[0067] Table 1 The raw material composition of the degradable polymer in Example 1

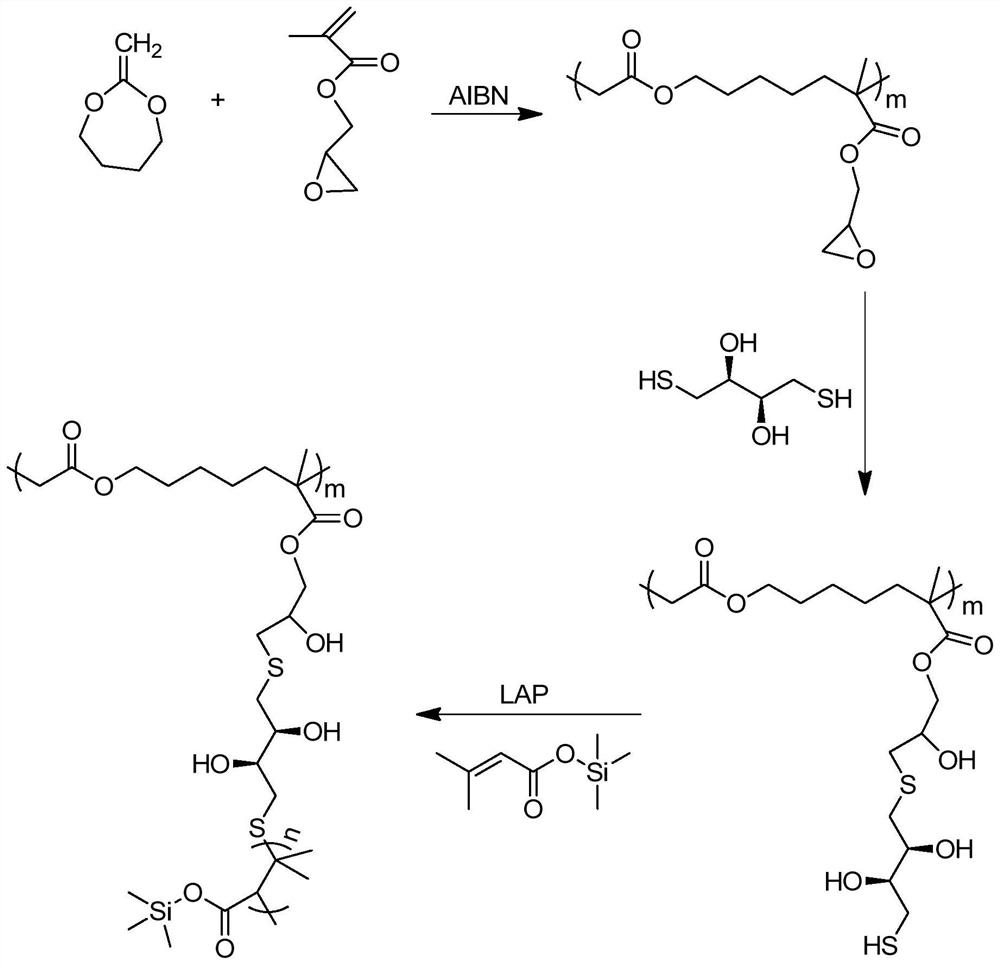

[0068] raw material parts by mass 2-Methylene-1,3-dioxepane 5 Glycidyl methacrylate 6 Azobisisobutyronitrile (AIBN) 0.05 Dithiothreitol 1.15 Trimethylsilyl 3,3-dimethacrylate 15.4 Lithium phenyl-2,4,6-trimethylbenzoylphosphonate (photoinitiator LAP) 0.03

[0069] The preparation steps of the degradable polymer in this example are as follows:

[0070] 1) In a reaction vessel under nitrogen atmosphere, add 5 parts by mass of 2-methylene-1,3-dioxepane, 6 parts by mass of glycidyl methacrylate, 0.05 parts by mass of AIBN and 40 parts by mass of dioxane Methyl chloride was reacted at 70°C for 3 hours to obtain a polymer containing an ethylene oxide group in the side chain;

[0071] 2) In the first step product solution, add 6.5 parts by...

Embodiment 2

[0075] The raw materials for the preparation of the degradable polymer in this example are shown in Table 2.

[0076] The raw material composition of table 2 embodiment 2 degradable polymer

[0077]

[0078]

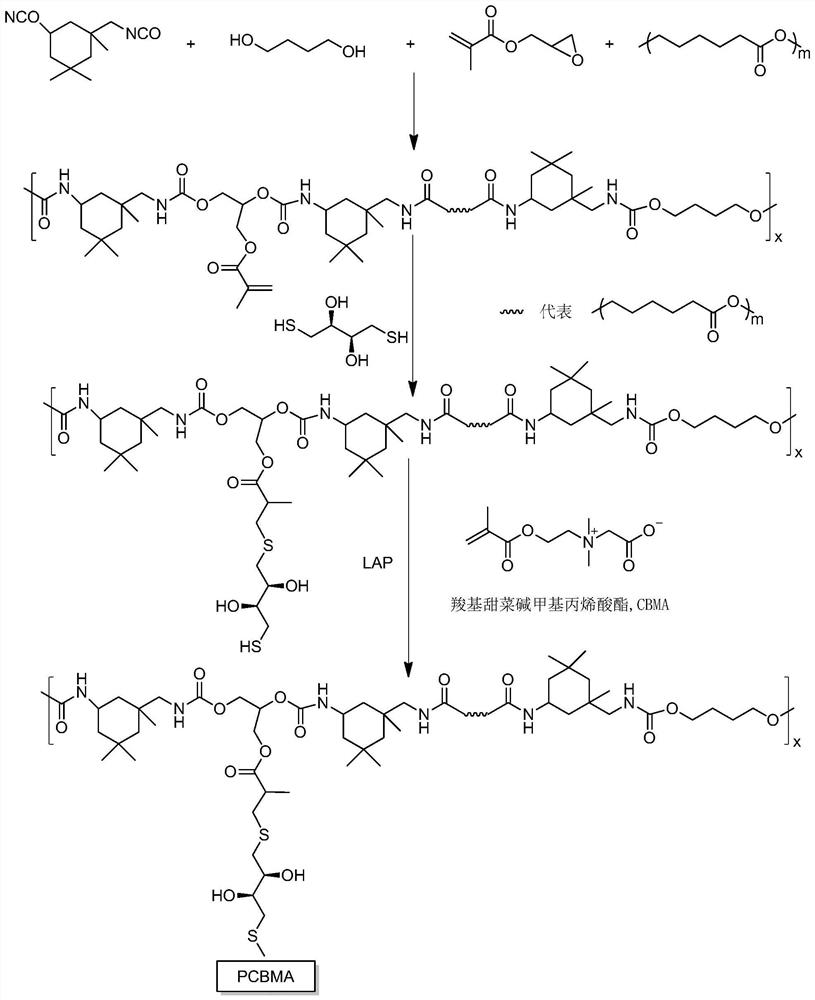

[0079] The preparation steps of the degradable polymer in this example are as follows:

[0080] 1) In a reaction vessel under nitrogen atmosphere, 5 parts by mass of isophorone diisocyanate, 2 parts by mass of 1,4-butanediol, 4.5 parts by mass of poly(L-lactide-caprolactone), 0.6 parts by mass were added Glycidyl methacrylate and 50 parts of tetrahydrofuran were reacted at 70° C. for 1 hour to obtain the first-step product with an ethylene oxide group in the side chain;

[0081] 2) In the first step reaction solution, add 0.7 parts by mass of dithiothreitol (the molar ratio of dithiothreitol to carboxybetaine methacrylate is 1:15) and react under neutral, 37° C. conditions for 3 hours, the second-step product containing sulfhydryl in the side chain is prepared; ...

Embodiment 3

[0085] The raw materials for the preparation of the degradable polymer in this example are shown in Table 3.

[0086] The raw material composition of table 3 embodiment 3 degradable polymer

[0087] raw material parts by mass Toluene Diisocyanate 5 1,4-Butanediol 2.6 Poly(L-lactide-caprolactone) 4.5 Thioglycerol 0.6 GAMMA-butyrolactone-3-yl methacrylate 10 Lithium phenyl-2,4,6-trimethylbenzoylphosphonate (photoinitiator LAP) 0.03

[0088] The preparation steps of the degradable polymer in this example are as follows:

[0089] 1) In a reaction vessel in a nitrogen atmosphere, 5 parts by mass of toluene diisocyanate, 2.6 parts by mass of 1,4-butanediol, 4.5 parts by mass of poly(L-lactide-caprolactone) (molecular weight 1000), 0.6 parts by mass Parts of thioglycerol and 50 parts of tetrahydrofuran were reacted at 70° C. for 1 hour to obtain the first-step product with a sulfhydryl group in the side chain;

[0090] 2) In the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com