Reverse osmosis membrane and preparation method and application thereof

A technology of reverse osmosis membrane and composite membrane, applied in the field of separation membrane, can solve the problem of poor pollution resistance of reverse osmosis membrane, and achieve the effects of improving anti-pollution ability, improving hydrophilicity and improving salt interception rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention also provides the preparation method of above-mentioned reverse osmosis membrane, and this method comprises the following steps:

[0041] (1) forming a polyamide separation layer on one surface of the support layer to obtain a composite membrane;

[0042] (2) In the presence of a curing agent, the composite film obtained in step (1) is contacted with an ammonium salt containing epoxy groups, so that the epoxy groups in the ammonium salts containing epoxy groups and the polyamide A crosslinking reaction occurs.

[0043] In the method of the present invention, there is no special limitation for the support layer, it can be made of various existing materials with certain strength and can be used for nanofiltration and reverse osmosis membranes, usually polyester, One or more of polyacrylonitrile, polyvinylidene fluoride, phenolphthalein non-sulfonated polyarylethersulfone, polyethersulfone and polysulfone. In addition, the support layer can be a sin...

preparation example 1

[0082] The upper surface of the support layer (the surface of the polysulfone layer, the same below) is contacted with an aqueous solution of m-phenylenediamine with a concentration of 2% by weight, and the liquid is drained after contacting at 25°C for 10 seconds; The Isopar E solution of the trimellitic chloride solution was drained after contacting at 25°C for 10s; then, the membrane was put into an oven and heated at 70°C for 3min to obtain a reverse osmosis membrane M1, which included a support layer and a separation layer, wherein, The thickness of the separation layer was 0.15 μm.

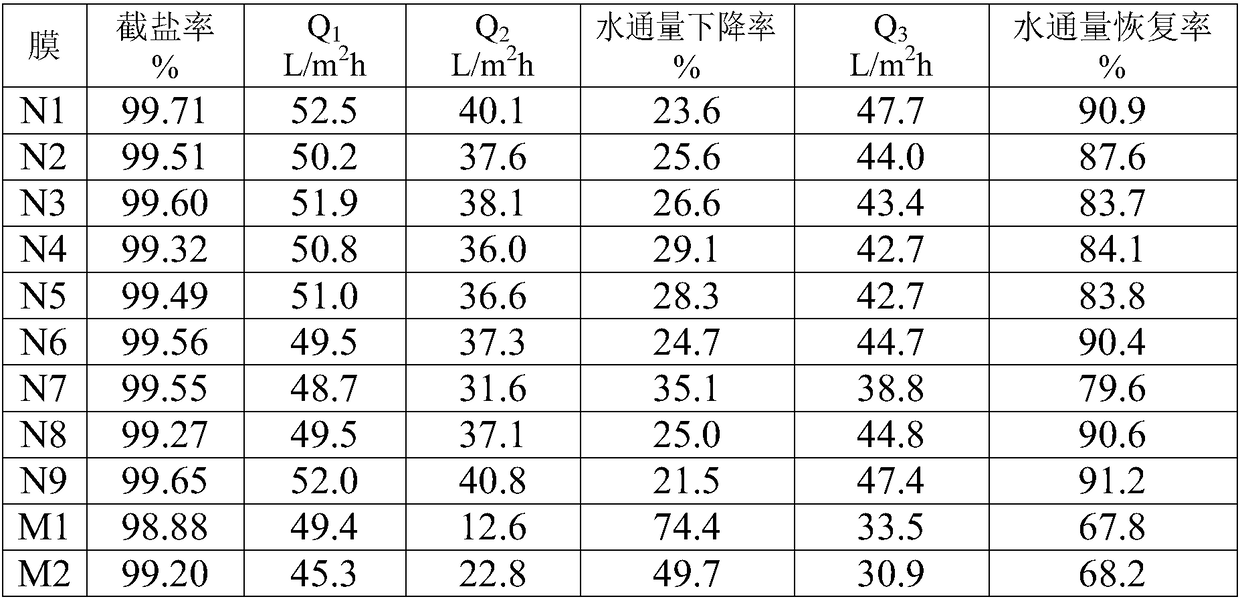

[0083] After immersing the obtained reverse osmosis membrane M1 in water for 24 hours, measure the water flux Q at a pressure of 1.55MPa and a temperature of 25°C 1 And the desalination rate to NaCl (2000ppm), the results are shown in Table 1. And under the same temperature and pressure conditions, test its fouling resistance, the membrane in the mixed aqueous solution containing 2000ppmNaC...

preparation example 2

[0085] At 25°C, the reverse osmosis membrane M1 prepared according to the method of Preparation Example 1 was immersed in an aqueous solution containing 2% by weight of polyvinyl alcohol, 0.1% by weight of glutaraldehyde, and a pH of 2 for 30s. After taking it out, the membrane was put into an oven at 70°C and heated for 5 minutes to obtain a pollution-resistant reverse osmosis membrane M2 with a surface-modified membrane formed on the upper surface of the polyamide separation layer, wherein the thickness of the surface-modified membrane was 0.12 μm.

[0086] After immersing the obtained reverse osmosis membrane M2 in water for 24 hours, measure the water flux Q at a pressure of 1.55MPa and a temperature of 25°C 1 And the desalination rate to NaCl (2000ppm), the results are shown in Table 1. And under the same temperature and pressure conditions, test its fouling resistance, the membrane in the mixed aqueous solution containing 2000ppmNaCl and 1000ppm hexadecyltrimethylammoniu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com