Composite forward osmosis membrane and preparation method thereof

A technology of forward osmosis membrane and membrane material, which is applied in the field of composite forward osmosis membrane and its preparation, can solve the problem of low membrane flux, achieve high salt interception rate, stable and reliable preparation method, and improve the effect of water flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

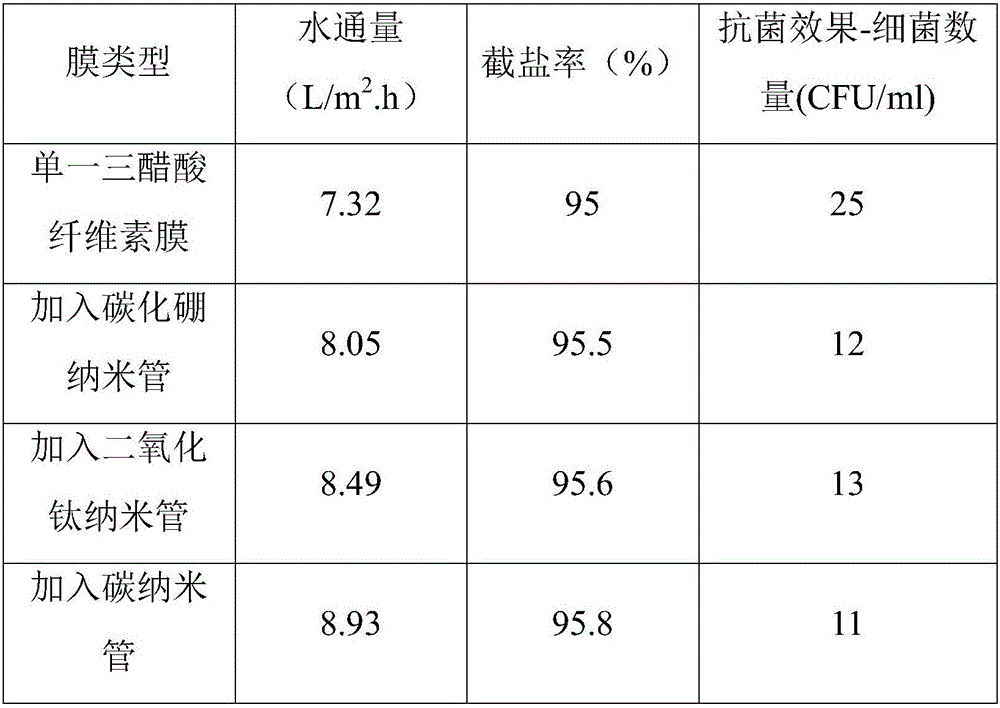

Examples

Embodiment 1

[0038] Surface modification of boron carbide nanotubes:

[0039] Use ammonium oleate aqueous solution as anionic surfactant, mix at a ratio of 4 mg nanotubes per 1 ml of surfactant, ultrasonically disperse for 3 hours, filter and dry at 80 degrees Celsius

[0040] Prepare the composite forward osmosis membrane according to the following steps:

[0041] 1) Pretreatment of nanotube materials:

[0042] The nanotube material was mixed with a 0.01 mol / L silver nitrate solution, and then a reducing agent was added and heated and stirred at 40°C for 6 hours, cooled to room temperature, filtered, and dried at 40-60°C.

[0043] 2) Pretreatment of support materials;

[0044] Soak the support material with an alkaline solution of pH 12, sonicate for 60 minutes, then rinse with deionized water and dry;

[0045] 3) Prepare membrane solution:

[0046] In terms of weight percentage, 2% nanotube material and 20% cellulose triacetate are added to a mixed solvent of 55% 1,4-dioxane, 12% acetone, 6% methanol...

Embodiment 2

[0051] Surface modification of titanium dioxide nanotubes:

[0052] After mixing 1 gram of nanotube powder and 10 ml of phenyl dichloride phosphate, ultrasonically disperse for 30 minutes, then pass in nitrogen, reflux at 90 degrees Celsius for 5 hours, keep stirring, and then slowly add excess Deionized water was filtered to obtain a solid product. After the solid product was obtained, in order to remove the excess phenyl dichloride phosphate, the product was placed in a Soxhlet extractor, and tetraoxyfuran was used as a solvent to extract the solid The product was produced for 36 hours and dried at 80 degrees Celsius.

[0053] Prepare the composite forward osmosis membrane according to the following steps:

[0054] 1) Pretreatment of nanotube materials:

[0055] The nanotube material was mixed with a 0.01 mol / L silver nitrate solution, and then a reducing agent was added and heated and stirred at 40°C for 6 hours, cooled to room temperature, filtered, and dried at 40-60°C.

[0056] ...

Embodiment 3

[0064] Surface modification of carbon nanotubes:

[0065] The nitric acid solution with a concentration of 3mol / L is added to a three-necked flask containing carbon nanotubes, and after mixing and uniformity, it is fixed to a water bath device heated to 80 degrees Celsius in advance, and the condensed water and electric stirring device are turned on. Time, turn off the electric stirring and water bath equipment power supply, cool to room temperature, suction filter the reaction product, wash with distilled water to neutral, get the upper black solid, and then put the upper black solid into the drying box to dry for 24 hours, get the carboxylated carbon nano Tube for use.

[0066] Prepare the composite forward osmosis membrane according to the following steps:

[0067] 1) Pretreatment of nanotube materials:

[0068] The nanotube material was mixed with a 0.01 mol / L silver nitrate solution, and then a reducing agent was added and heated and stirred at 40°C for 6 hours, cooled to room t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com