Antibacterial shape memory polyurethane orthopedic, fixing and rehabillitative plate and preparation method thereof

A technology of polyurethane and polyurethane solution, which is applied in fractures, medical science, and pharmaceutical formulations, etc. It can solve the problems that splints do not have antibacterial function, are expensive, and breed bacteria, and achieve the effects of wide application range, low cost, and strong air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

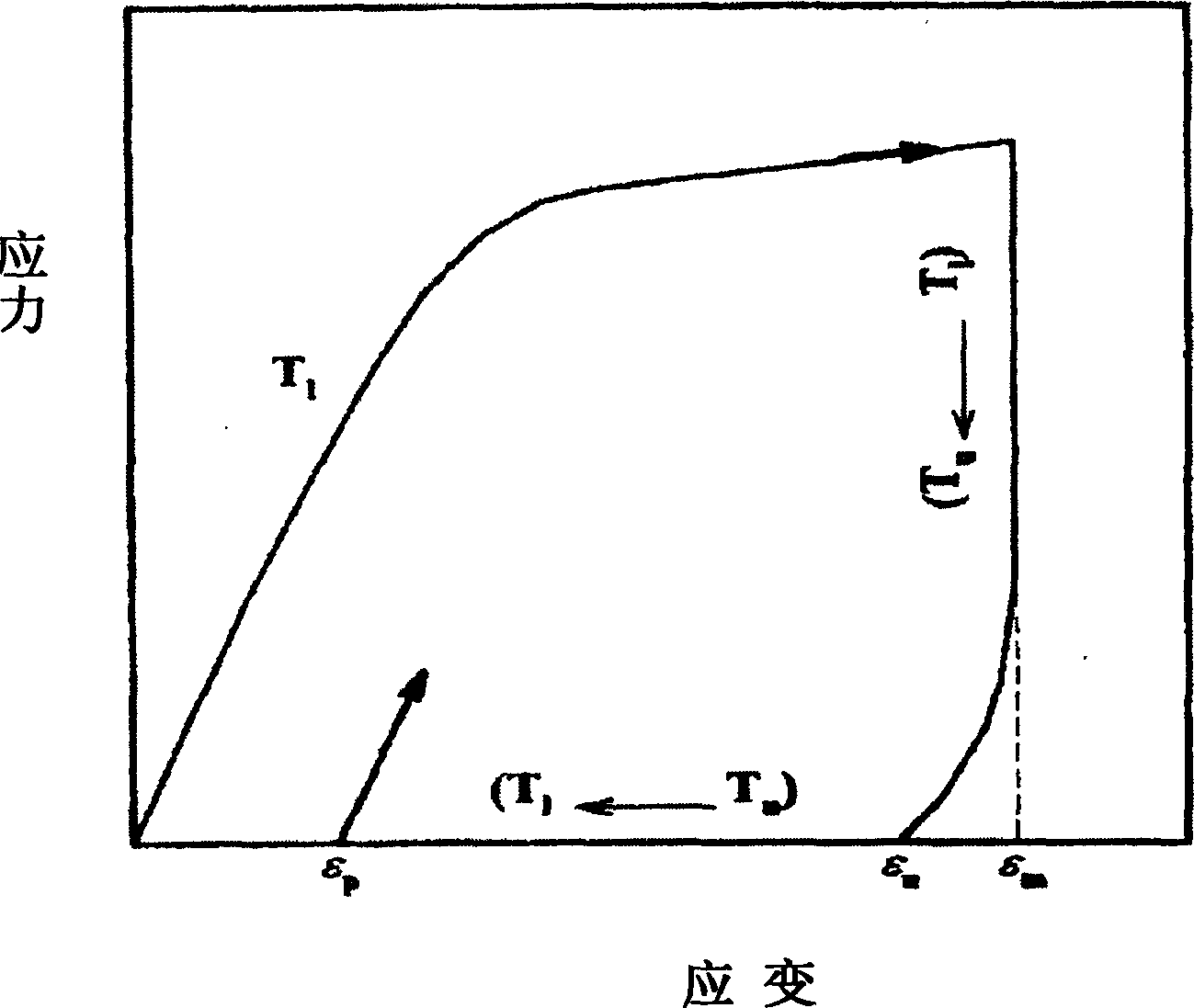

Method used

Image

Examples

Embodiment 1

[0054] Add 100 kg of reversible phase components polycaprolactone diol (number-average molecular mass: 10,000), 5.0 kg of 4,4'-xylene methane diisocyanate, and 500 kg of dimethylformamide into 1000L with agitator and thermometer And in the reaction kettle of the reflux condenser, react at a temperature of 75-80°C for 2 hours. Then add 5.4 kg of stationary phase components 1,4-butanediol, 2.38 kg of N-methyldiethanolamine, 17.5 kg of 4,4'-diphenylmethane diisocyanate, control the temperature at 80-85°C, and react for 3-4 hours Finally, 80.0 kg of dimethylacetamide was added to adjust the viscosity to obtain a colorless to light yellow, viscous polyurethane solution.

[0055] Through theoretical calculation, the mass percentage of the stationary phase in the polyurethane obtained in this example is 23.2%; the mass percentage of the reversible phase of the reversible phase is 76.8%; the crystallization melting point temperature of the reversible phase and the glass transition tem...

Embodiment 2

[0057] The reversible phase component polyethylene adipate diol (PHEP, relative molecular weight 4000) 40 grams, polybutylene adipate diol (PHB) 40 grams, 2,4-toluene diisocyanate 6.96 gram, 150 grams of dimethyl sulfoxide was added into a 500 mL reaction kettle equipped with a stirrer, a thermometer and a reflux condenser, and reacted at a temperature of 80° C. for 2-3 hours. Then add 4.05 grams of N-methyldiethanolamine, 4.72 grams of 1,6-hexanediol, 18.25 grams of 4,4'-diphenylmethane diisocyanate, and control the temperature at 75-80 ° C for 3-4 hours Finally, 100 grams of dimethylformamide was added to adjust the viscosity to obtain a colorless to light yellow, viscous polyurethane solution.

[0058] Through theoretical calculation, the mass percentage of the stationary phase in the polyurethane obtained in this example is 30%; the mass percentage of the reversible phase of the reversible phase is 70%; the crystallization melting point temperature of the reversible phase ...

Embodiment 3

[0060] The reversible phase component polyethylene adipate diol (PHEP, relative molecular mass 1000) 15 kilograms, polybutylene adipate diol (PHB, relative molecular mass 2000) 15 kilograms, 2,4 - Add 6.83 kg of methane diisocyanate and 100 kg of dimethylformamide into a 500 L reaction kettle equipped with a stirrer, a thermometer and a reflux condenser, and react at a temperature of 75-80° C. for 2.5 hours. Then add 1.56 kg of stationary phase components 1,2-ethanediol and 1.50 kg of diethylene glycol, 2.0 kg of nicotinamide, 5.0 kg of 4,4'-diphenylmethane diisocyanate, temperature control 75 ° C, reaction 3 After one hour, 100 grams of dimethylformamide was added to adjust the viscosity to obtain a colorless viscous polyurethane solution.

[0061] Through theoretical calculation, the mass percentage of the stationary phase in the polyurethane obtained in this embodiment is 35%; the mass percentage of the reversible phase of the reversible phase is 65%; the crystallization me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com