Multifunctional waffle cotton thermal batting and preparation method thereof

A honeycomb cotton, multi-functional technology, applied in the field of non-woven fabrics, can solve the problems of not being able to meet the requirements of strong warmth retention and high elasticity at the same time, and achieve the effect of improving product quality and service life, ensuring the separation of fiber web layers and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] A method for preparing the above-mentioned multifunctional honeycomb cotton thermal insulation wadding, the preparation method comprises the following steps in sequence:

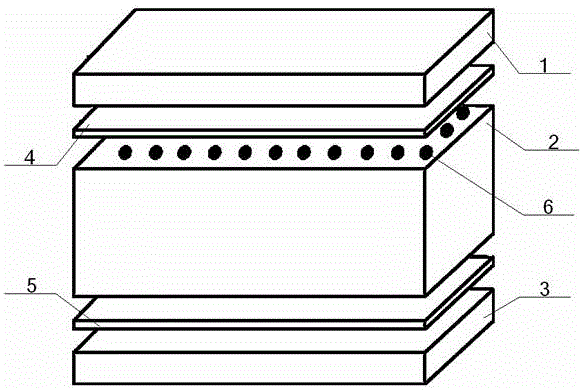

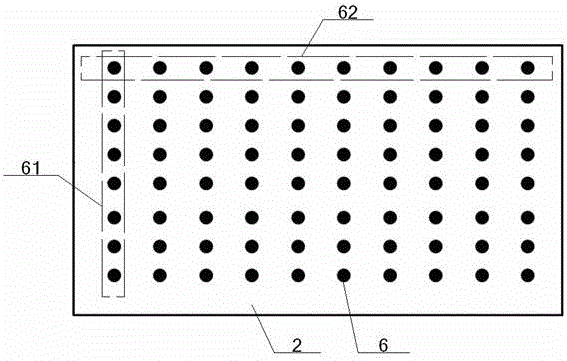

[0049] The preparation of each layer of fiber web: firstly, the textile raw materials are carded or air-laid, and then the surface layer fiber web 1 and the inner layer fiber web 3 are made by the process of cross-lapping. At the same time, the textile raw materials are carded into a web Then make the honeycomb cotton-like middle fiber web 2 through the process of vertical web laying;

[0050] Compositing of fiber webs of each layer: laying the surface fiber web 1 on the top surface of the middle layer fiber web 2, and at the same time, laying the middle layer fiber web 2 on the top surface of the inner layer fiber web 3 to obtain a composite fiber web;

[0051] Post-treatment process: sequentially drying, cooling, and winding the composite fiber web obtained above to obtain the multifunctional honeyc...

Embodiment 1

[0080] see Figure 1 to Figure 3 , a multifunctional honeycomb cotton thermal insulation flake, comprising a surface textile material layer, a middle textile material layer, and an inner textile material layer, the bottom surface of the surface textile material layer is connected to the top surface of the middle textile material layer, and the middle textile material layer The bottom surface is connected to the top surface of the inner textile material layer; the surface textile material layer is the surface fiber web 1, which is a fiber web formed by cross-lapping after carding or air-laid; the middle textile material layer It is the middle layer fiber web 2, which is honeycomb cotton formed by vertical laying after carding; the inner textile material layer is the inner layer fiber web 3, which is carded or air-laid and then cross-laid A web made of webs.

[0081] A method for preparing the above-mentioned multifunctional honeycomb cotton thermal insulation wadding, the prep...

Embodiment 2

[0086] Basic content is the same as embodiment 1, the difference is:

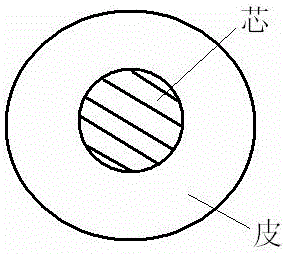

[0087] The composition and weight ratio of the middle fiber web 2 are: 70-80% of three-dimensional crimped hollow polyester staple fiber, 20-30% of low-melting point polyester staple fiber. The compositions and weight ratios of the surface layer fiber web 1 and the inner layer fiber web 3 are: 70-85% of antibacterial hollow polyester staple fibers with three-dimensional crimps, and 15-30% of low-melting point polyester staple fibers. The low-melting polyester staple fiber is a sheath-core polyester staple fiber, the melting point of the core is higher than that of the sheath, and the melting point of the sheath is less than or equal to 110 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com