Preparation method and regeneration method of renewable polyelectrolyte membrane for forward osmosis technology

A polyelectrolyte and forward osmosis technology, which is applied in the field of membrane treatment and preparation, can solve the problems of membrane pollution, concentration polarization and high membrane flux, achieve strong anti-pollution and corrosion resistance, reduce membrane pollution and long working life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

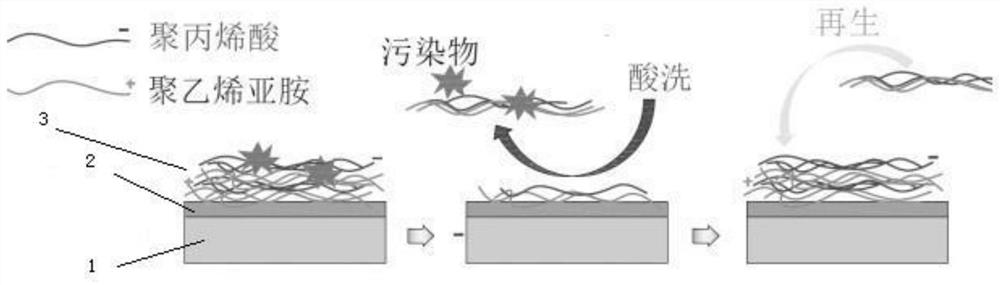

[0033] as attached figure 1 And attached figure 2 as shown,

[0034] The preparation method of the renewable polyelectrolyte membrane that is used for forward osmosis technology comprises the following steps:

[0035] Step 1, preparation of support layer polyethersulfone (PES) membrane

[0036] Prepared by phase inversion method: Take 20g of PES particles and 4.5g of polyvinylpyrrolidone (PVP K-30) powder and dissolve them in 80ml of N-methylpyrrolidone (NMP), shake in a water bath at 50°C for 6h, and after cooling Pour the film casting solution into a smooth glass plate, scrape out a 150 μm thick liquid film with a scraper, let it stand for 1 minute, and then put it in a hydrocoagulation bath to obtain a polyethersulfone film;

[0037] Step 2, preparation of selection layer

[0038] Soak the PES membrane in 2gL -1 In the dopamine solution, the solution was exposed to the air for 5h, and the dopamine solution consisted of 200mg of dopamine dissolved in 100ml of Tri-HCl (...

Embodiment 2

[0047] The preparation method of the renewable polyelectrolyte membrane that is used for forward osmosis technology comprises the following steps:

[0048] Step 1, preparation of support layer polyethersulfone (PES) membrane

[0049] Prepared by phase inversion method: Dissolve 16g of PES granules and 2g of polyvinylpyrrolidone (PVP K-30) powder in 75ml of N-methylpyrrolidone (NMP), shake it in a water bath at 50°C for 4 hours, and cast it after cooling Pour the membrane solution into a smooth glass plate, scrape out a 100 μm thick liquid membrane with a scraper, let it stand for 1 minute, and then use a hydrocoagulation bath to obtain a polyethersulfone membrane;

[0050] Step 2, preparation of selection layer

[0051] Soak the PES membrane in 1.3gL -1In the dopamine solution, the solution was exposed to the air for 5h, and the dopamine solution consisted of 200mg of dopamine dissolved in 100ml of Tri-HCl (10mmolL -1 , pH 8.5) solution obtained polyethersulfone membrane af...

Embodiment 3

[0060] The preparation method of the renewable polyelectrolyte membrane that is used for forward osmosis technology comprises the following steps:

[0061] Step 1, preparation of support layer polyethersulfone (PES) membrane

[0062] Prepared by phase inversion method: Dissolve 18g of PES granules and 2.8g of polyvinylpyrrolidone (PVP K-30) powder in 78ml of N-methylpyrrolidone (NMP), shake in a water bath at 50°C for 4h, cool Pour the film casting solution into a smooth glass plate, scrape out a 130μm thick liquid film with a scraper, let it stand for 1 minute, and then put it in a hydrocoagulation bath to obtain a polyethersulfone film;

[0063] Step 2, preparation of selection layer

[0064] Soak the PES membrane in 1.8gL -1 In the dopamine solution, the solution was exposed to the air for 5h, and the dopamine solution consisted of 200mg of dopamine dissolved in 100ml of Tri-HCl (10mmolL -1 , pH 8.5) solution obtained polyethersulfone membrane after self-polymerization o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com