Preparation method of chlorine-resistant pollution-resistant polyamide reverse osmosis membrane

A reverse osmosis membrane and pollution-resistant technology, applied in the field of preparation of polyamide reverse osmosis membrane, can solve the problems of poor chlorine resistance and pollution resistance of polyamide reverse osmosis membrane, no cycle reversibility, etc. The effect of improving water flux and pollution resistance, excellent chlorine resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

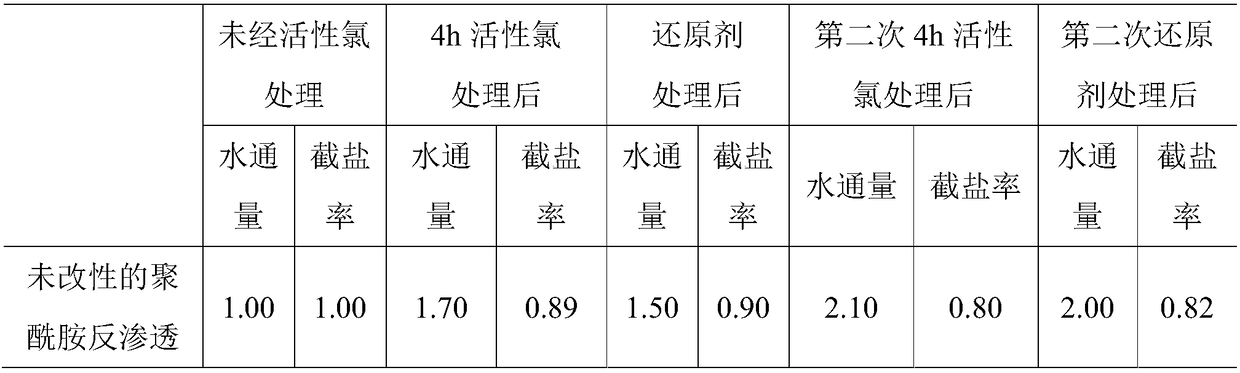

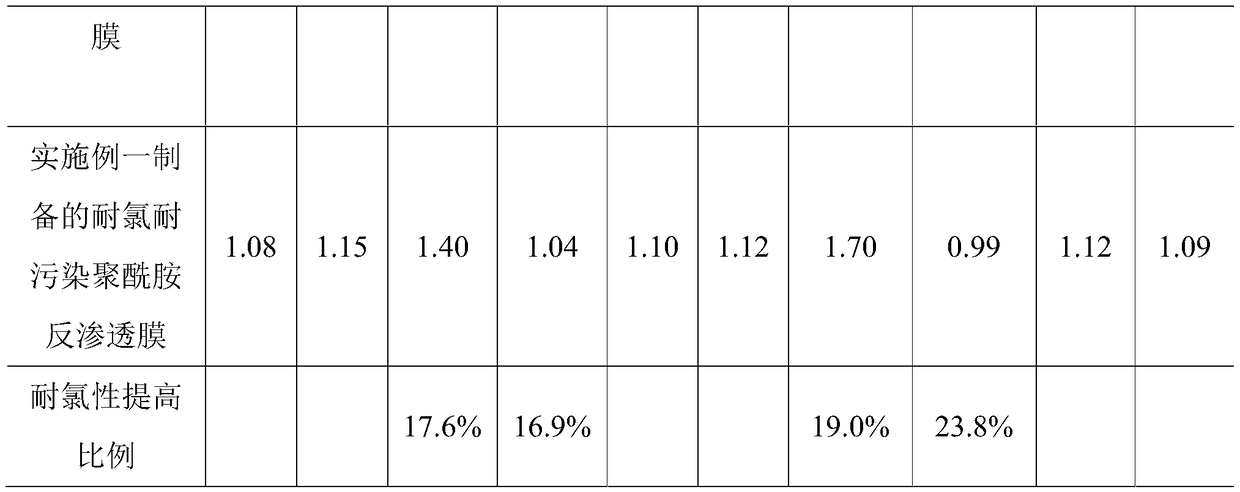

Examples

specific Embodiment approach 1

[0027] Specific embodiment one: the preparation method of a kind of anti-chlorine anti-pollution polyamide reverse osmosis membrane of this embodiment is to carry out according to the following steps:

[0028] 1. Preparation of organic nanofiber dispersion:

[0029] Grind the high-performance organic fibers containing amino groups to grow into 1 μm ~ 20 μm with a fiber grinder to obtain the ground organic fibers, put the ground organic fibers in the reaction kettle, and add dimethyl sulfoxide to the reaction kettle , and heat up to 100°C to 200°C, adjust the speed to 200r / min to 1000r / min, stir and reflux for 2h to 5h to obtain a mixed solution, pass the mixed solution through a 10,000-mesh filter to remove undispersed organic fibers to obtain a dispersion , centrifuging the dispersion for 3 minutes to 15 minutes at a rotational speed of 3000r / min to 10000r / min, and then dispersing the precipitate into deionized water to obtain an organic nanofiber dispersion;

[0030] The ma...

specific Embodiment approach 2

[0047] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the high-performance organic fiber containing amine-based structure described in step 1 is poly 2,5-dihydroxy-1,4-phenylene pyridimidazole fiber, polyparaphenylenebenzimidazole fiber or aramid fiber. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0048] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in Step 1, the high-performance organic fiber containing amine structure is ground with a fiber grinder to grow to 1 μm to 5 μm, and the ground organic fiber is obtained. Fiber, put the ground organic fiber in the reaction kettle, add dimethyl sulfoxide into the reaction kettle, and raise the temperature to 100°C~155°C, adjust the speed to 300r / min~1000r / min, stir and reflux for 3h~5h , to obtain a mixed solution, pass the mixed solution through a 10000-mesh filter to remove undispersed organic fibers to obtain a dispersion, centrifuge the dispersion for 3min to 10min at a speed of 3000r / min to 8000r / min, and then remove the precipitate The mixture was dispersed in deionized water to obtain a dispersion of organic nanofibers. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com