Composite nanofiltration membrane containing organically modified attapulgite and preparation method thereof

A technology of composite nanofiltration membrane and attapulgite, which is applied in the field of composite nanofiltration membrane containing organically modified attapulgite and its preparation, can solve the problem of large specific surface area of attapulgite, poor affinity of organic polymers, surface High activity and other problems, to achieve the effect of mild reaction conditions, improved performance, and simple experimental process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

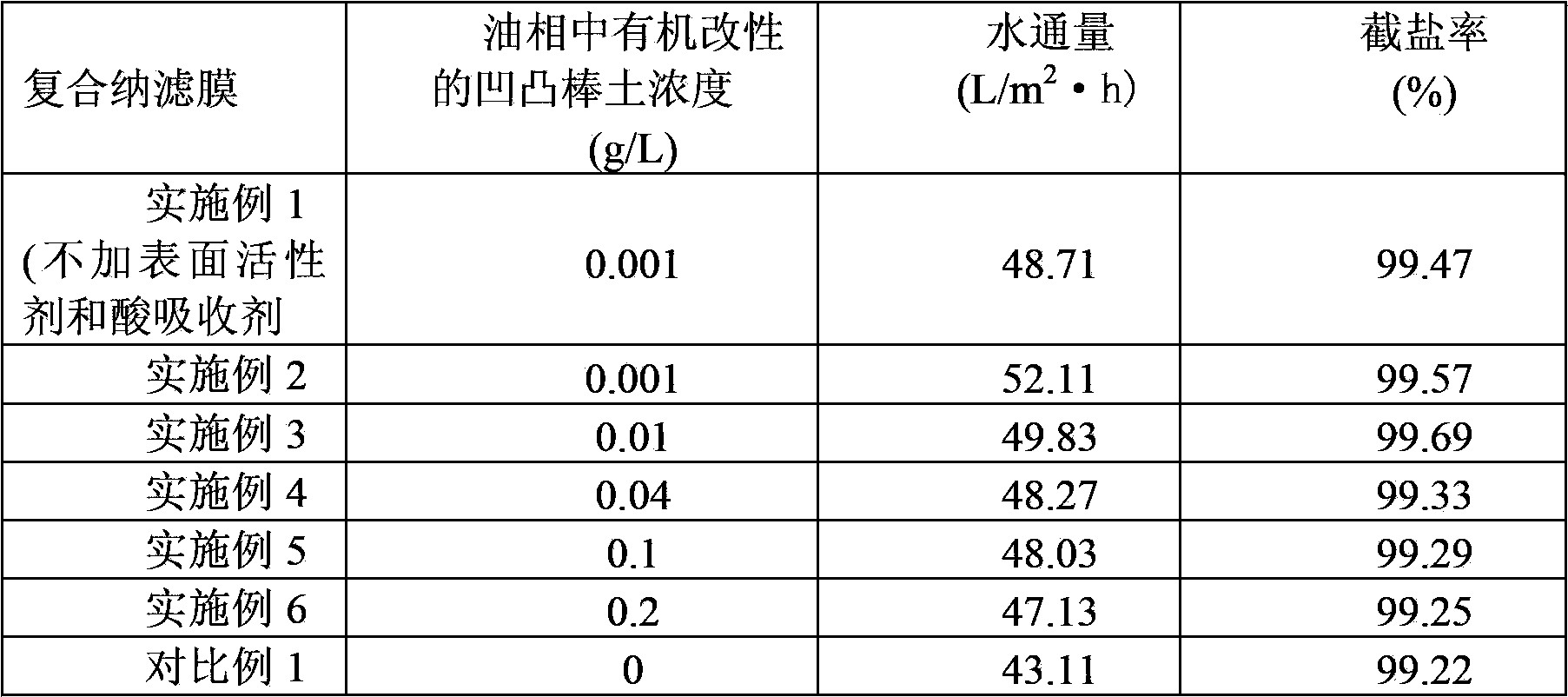

Embodiment 1

[0062] The specific purification steps of the attapulgite used in the present embodiment are as follows:

[0063] Prepare an attapulgite aqueous solution with a mass concentration of 10%, add a dispersant sodium hexametaphosphate whose mass is 10% of the attapulgite mass, mechanically stir for 30 minutes, ultrasonically treat for 30 minutes, and centrifuge at 2000r / min ; Discard the supernatant and dry in an oven at 80°C;

[0064] The concrete steps of the attapulgite organic modification after purification in the present embodiment are as follows:

[0065] Prepare a purified attapulgite aqueous solution with a mass concentration of 10%, add hexadecyltrimethylammonium bromide powder whose mass is 20% of that of attapulgite; and react with magnetic stirring for 2 hours at 70°C; After the above reaction solution was centrifuged (2000r / min) for a certain period of time, the supernatant was discarded; the modified attapulgite was dried in an oven at 80°C, cooled and then ground w...

Embodiment 2

[0069] The purification and organic modification steps of the attapulgite used in this example are the same as in Example 1.

[0070] Use a polysulfone porous support membrane with a molecular weight cut-off of 30,000 to 50,000, contact with a piperazine (PIP) aqueous phase solution with a concentration of 5g / L for about 30 seconds, wherein the piperazine aqueous phase solution contains 5g / L triethylamine (TEA ), 4g / L sodium dodecyl sulfate (SDS), the polysulfone support membrane soaked by the piperazine aqueous phase solution was removed with a rubber roller to remove excess solution. Then this supporting membrane is contacted with the n-hexane solution of trimesoyl chloride of 1g / L with concentration for 2 minutes, wherein the organically modified attapulgite of 0.001g / L is contained in the organic phase solution of trimesoyl chloride; The polyamide layer was dried in the air, placed in a 40°C oven for 8 minutes, and then rinsed in 40°C water for 10 minutes to obtain a polyp...

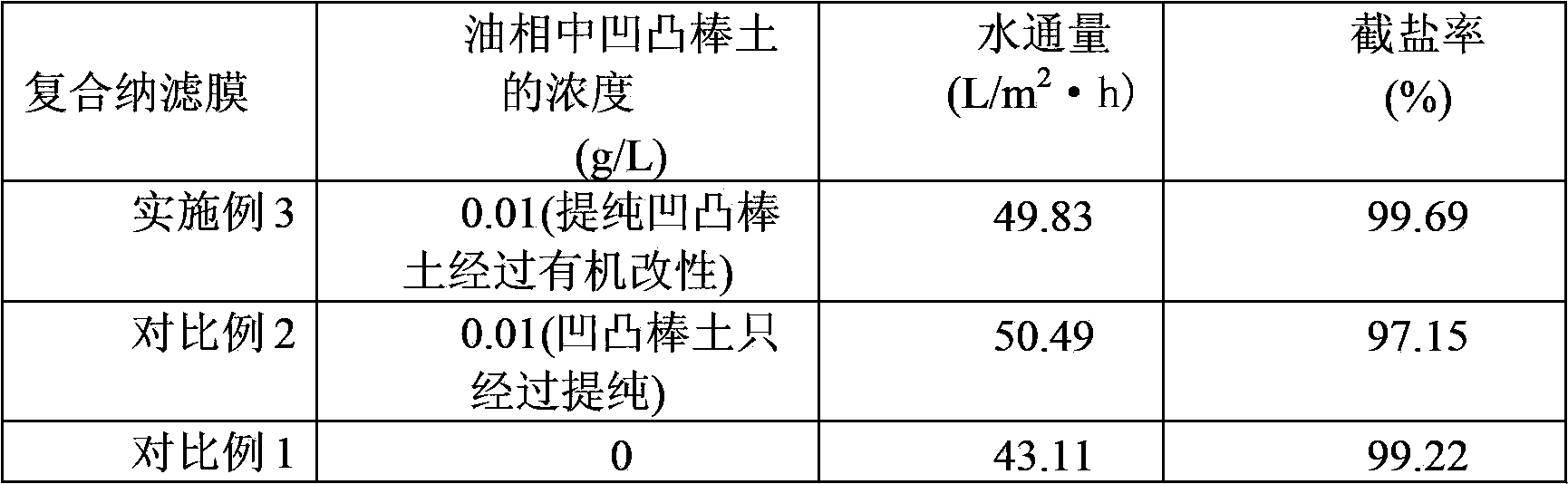

Embodiment 3

[0073] The purification and organic modification steps of the attapulgite used in this example are the same as in Example 1.

[0074] Use a polysulfone porous support membrane with a molecular weight cut-off of 30,000 to 50,000 to contact with a piperazine (PIP) aqueous phase solution with a concentration of 5 g / L for about 1 minute, wherein the piperazine aqueous phase solution contains 5 g / L of sodium carbonate (Na 2 CO 3 ), 1g / L sodium dodecyl sulfate (SDS), and the polysulfone support membrane soaked by the piperazine aqueous phase solution was removed with a rubber roller to remove excess solution. Then this supporting membrane is contacted with the cyclohexane solution of the isophthaloyl chloride of 1g / L with concentration for 1 minute, wherein the organically modified attapulgite of 0.01g / L is contained in the trimesoyl chloride organic phase solution; then Dry the formed polyamide layer in the air, place it in an oven at 40°C for 10 minutes, and then rinse it in wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com