Anti-biological pollution ultrafiltration membrane based on quaternary ammonium salt composite layered double hydroxide and preparation method thereof

A technology of anti-biological pollution and double hydroxide, which is applied in the field of membrane separation, can solve limitations and other problems, and achieve the effects of high hydrophilicity, environmentally friendly preparation process, and easy industrial scale-up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

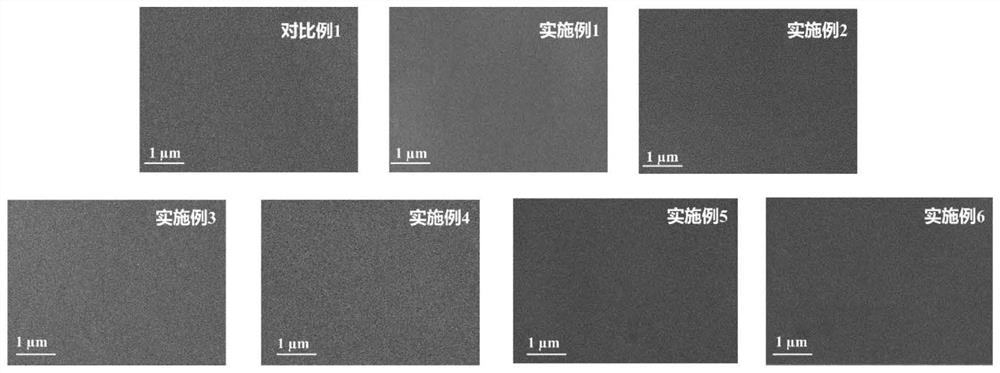

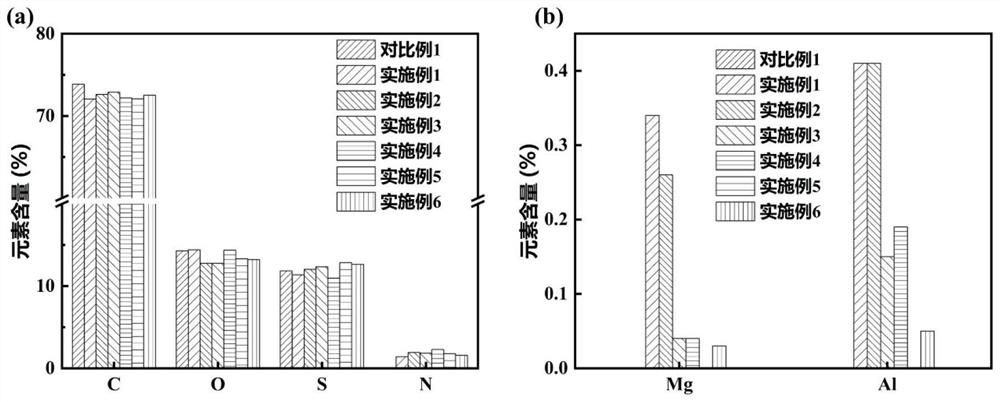

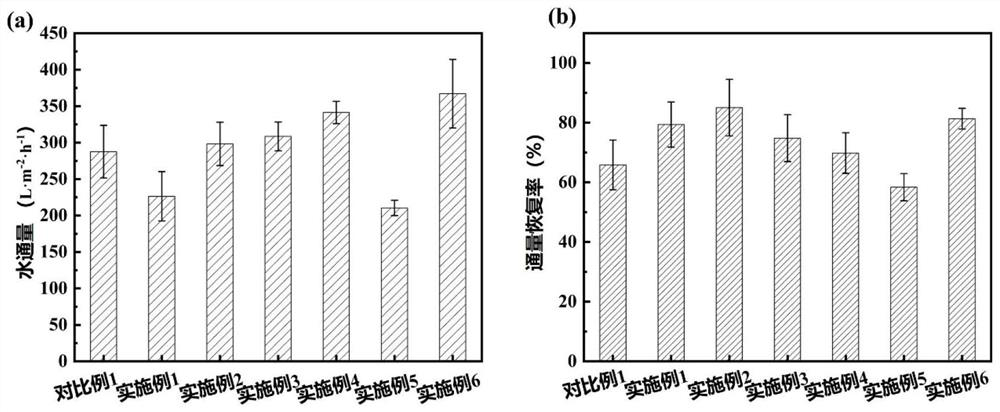

[0034] (1) Preparation of quaternary ammonium salt composite LDH nanosheets: According to the weight ratio of quaternary ammonium salt to LDH nanosheets of 1:2, take 0.2g of cetyltrimethylammonium bromide and 0.4g of MgAl-LDH to disperse In deionized water, the mixture was stirred at room temperature for 8 h, centrifuged, washed and dried to obtain MgAl-LDH nanosheets composited with cetyltrimethylammonium bromide.

[0035] (2) Preparation of casting solution: the weight ratio of quaternary ammonium salt composite LDH nanosheets to polyethersulfone powder is 1:30, the weight ratio of quaternary ammonium salt composite LDH nanosheets to porogen is 1:8, and the quaternary ammonium salt composite LDH nanosheets to porogen The weight ratio of the salt composite LDH nanosheets to the solvent is 1:127, taking 0.6wt% cetyltrimethylammonium bromide composite MgAl-LDH, 18wt% polyethersulfone powder and 5wt% polyvinylpyrrolidone ( Molecular weight of 58000 Da) was added to 76.4 wt% N-me...

Embodiment 2

[0039] (1) Preparation of quaternary ammonium salt composite LDH nanosheets: According to the weight ratio of quaternary ammonium salt to LDH nanosheets of 1:1, take 0.3g of cetyltrimethylammonium bromide and 0.3g of MgAl-LDH to disperse In deionized water, the mixture was stirred at room temperature for 8 h, centrifuged, washed and dried to obtain MgAl-LDH nanosheets composited with cetyltrimethylammonium bromide.

[0040](2) Preparation of casting solution: the weight ratio of quaternary ammonium salt composite LDH nanosheets to polyethersulfone powder is 1:30, the weight ratio of quaternary ammonium salt composite LDH nanosheets to porogen is 1:8, and the quaternary ammonium salt composite LDH nanosheets to porogen The weight ratio of the salt composite LDH nanosheets to the solvent is 1:127, taking 0.6wt% cetyltrimethylammonium bromide composite MgAl-LDH, 18wt% polyethersulfone powder and 5wt% polyvinylpyrrolidone ( Molecular weight of 58000 Da) was added to 76.4 wt% N-met...

Embodiment 3

[0044] (1) Preparation of quaternary ammonium salt composite LDH nanosheets: According to the weight ratio of quaternary ammonium salt to LDH nanosheets of 2:1, take 0.4g of cetyltrimethylammonium bromide and 0.2g of MgAl-LDH to disperse In deionized water, the mixture was stirred at room temperature for 8 h, centrifuged, washed and dried to obtain MgAl-LDH nanosheets composited with cetyltrimethylammonium bromide.

[0045] (2) Preparation of casting solution: the weight ratio of quaternary ammonium salt composite LDH nanosheets to polyethersulfone powder is 1:30, the weight ratio of quaternary ammonium salt composite LDH nanosheets to porogen is 1:8, and the quaternary ammonium salt composite LDH nanosheets to porogen The weight ratio of the salt composite LDH nanosheets to the solvent is 1:127, taking 0.6wt% cetyltrimethylammonium bromide composite MgAl-LDH, 18wt% polyethersulfone powder and 5wt% polyvinylpyrrolidone ( Molecular weight of 58000 Da) was added to 76.4 wt% N-me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com