Anti-biological-pollution composite reverse osmosis membrane and preparation method thereof

An anti-biological fouling and reverse osmosis membrane technology, applied in reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problem of poor anti-biological fouling of polyamide desalination layer, reduce the washing frequency of reverse osmosis membrane, and water flux Low-level problems, achieve good antibacterial and hydrophilic properties, excellent adsorption properties, and widen the effect of flow channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

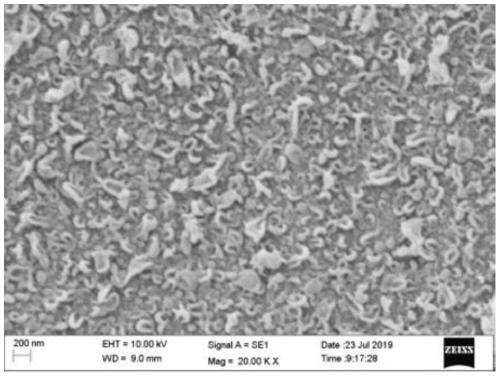

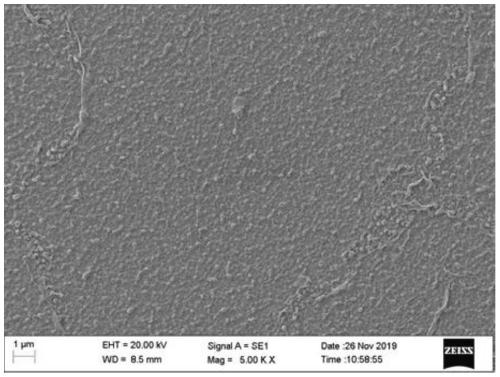

Image

Examples

Embodiment 1

[0029] A preparation of anti-biological fouling composite reverse osmosis membrane, the specific implementation steps are as follows:

[0030] (1) Weigh 10g of clay mineral montmorillonite and disperse it in deionized water, add 2g of guanidine-based modifier (guanidinoacetic acid) and ultrasonically mix evenly, then add ammonia water drop by drop until the pH of the solution is 8-9, and heat up under stirring React at 35°C for 2 hours, then filter the resulting mixture with suction, wash with ethanol until neutral, freeze-dry and grind to obtain modified clay minerals for later use;

[0031] (2) Dissolve 20g of citric acid and 10g of sodium hydroxide in deionized water and mix them uniformly to prepare an acid-binding agent, then add 20g of m-phenylenediamine, 1g of dopamine and 1g of modified clay mineral to the above-mentioned acid-binding agent in sequence, Dilute to 1000g with deionized water, disperse ultrasonically for 30 minutes to form a modified aqueous solution, and...

Embodiment 2~5

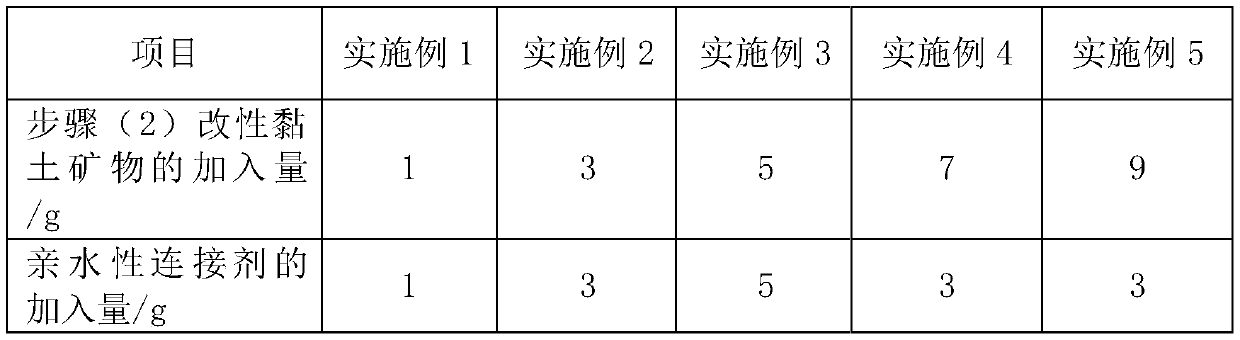

[0037] The preparation method of the anti-biological fouling composite reverse osmosis membrane in Examples 2 to 5 is basically the same as that of Example 1, the only difference being: the addition of modified clay minerals and hydrophilic linking agent added in step (2) different, as shown in Table 1:

[0038] Table 1

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com