Modified wholly aromatic polyamide membrane and preparation method thereof

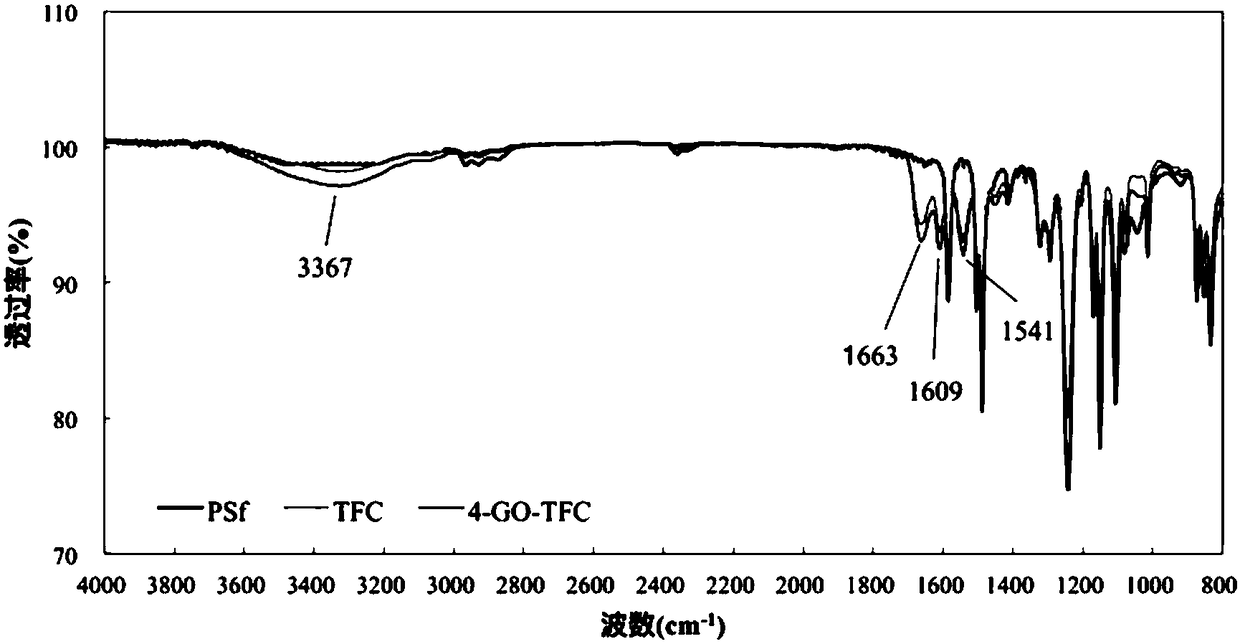

An aromatic polyamide membrane and a technology of wholly aromatic polyamide, which are applied in the field of alkene-modified wholly aromatic polyamide membrane and its preparation, can solve the problem of low water flux and energy efficiency, flux and anti-pollution performance need to be improved, popularized and applied Obstacles and other problems, to achieve the effect of improving the surface morphology, the preparation method is simple and feasible, and the ionic strength and organic pollution are small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A preparation method for the above modified wholly aromatic polyamide film, comprising the following steps:

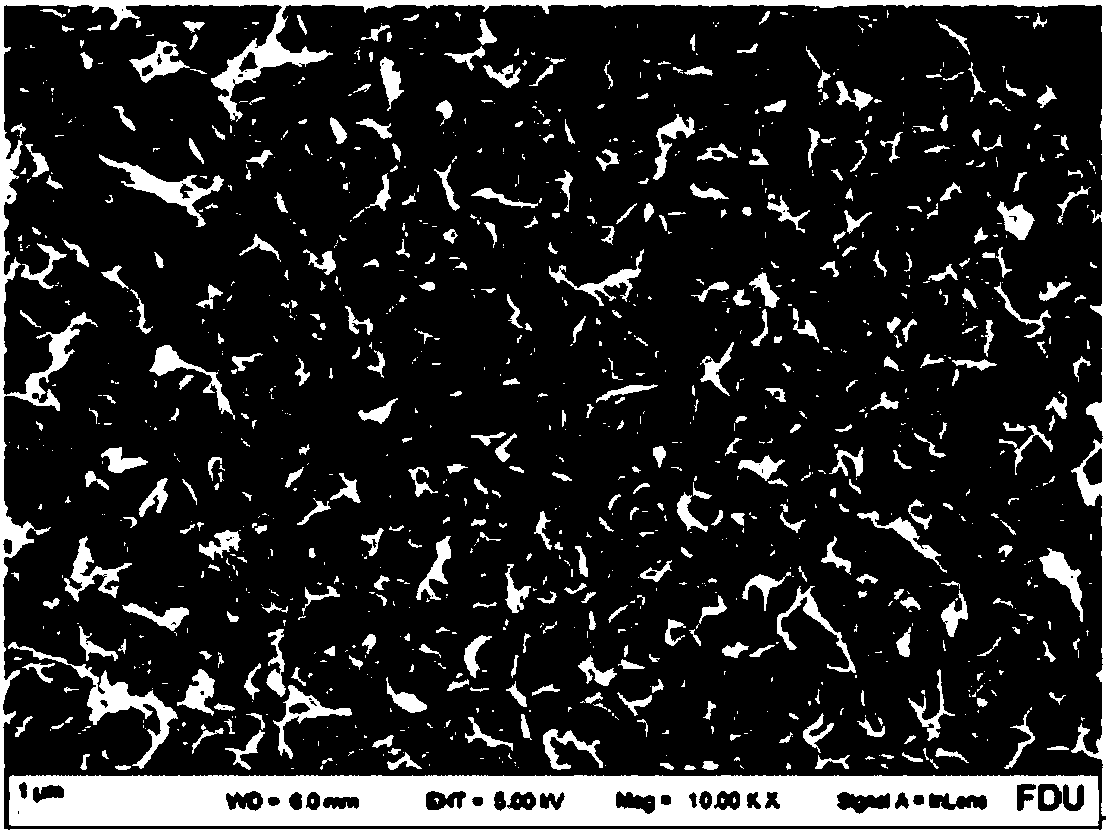

[0049]1. Dissolve graphene oxide nanosheets in water, disperse them by ultrasonication for 20 minutes to form a 0.1% graphene oxide stock solution, and soak the polysulfone ultrafiltration membrane in deionized water for 24 hours for later use.

[0050] 2. Adding different amounts of graphene oxide into 0.02 g / mL m-phenylenediamine aqueous solution to obtain a graphene oxide-containing m-phenylenediamine aqueous phase solution with a ratio of 0.004 wt % graphene oxide.

[0051] 3. Pour the m-phenylenediamine aqueous phase solution containing graphene oxide onto the surface of the polysulfone ultrafiltration membrane, take it out after immersion for 2 minutes, and remove the excess solution on the membrane surface with a rubber roller.

[0052] 4. After drying in air for 1 min, pour the n-hexane solution dissolved with 0.001 g / mL trimesoyl chloride onto the membr...

Embodiment 2

[0056] Using the same preparation method as in Example 1, the difference is that: in the m-phenylenediamine aqueous phase solution containing graphene oxide, the mass fraction of graphene oxide is 0.008wt%, and the finally obtained modified wholly aromatic polyamide The membrane is designated as 8-GO-TFC.

Embodiment 3

[0058] Using the same preparation method as in Example 1, the difference is that: in the m-phenylenediamine aqueous phase solution containing graphene oxide, the mass fraction of graphene oxide is 0.016wt%, and the finally obtained modified wholly aromatic polyamide The membrane is designated as 16-GO-TFC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com