Preparation method for composite forward osmosis membrane based on interfacial polymerization

An interfacial polymerization, forward osmosis membrane technology, used in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of unstable chemical properties, easy pollution, low porosity, etc., and achieve excellent chemical stability, Strong anti-pollution ability and the effect of enhancing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Step 1: Accurately weigh 2g polyvinyl alcohol, 18g polyvinylidene fluoride, 80g caprolactam, polyvinylidene fluoride vinyl / polyvinyl alcohol is 9:1, polymer material mass fraction is 20%, polyvinyl alcohol, polyvinylidene Mix vinyl fluoride and caprolactam evenly and pour them into a 250ml beaker. The temperature of the oil bath used is 115°C. The heating process requires nitrogen protection. Heat for 0.5 hours to dissolve polyvinyl alcohol, polyvinylidene fluoride and caprolactam, and then stir the solution with an electric stirrer for 1.5 hour, then leave it to stand to obtain the casting solution.

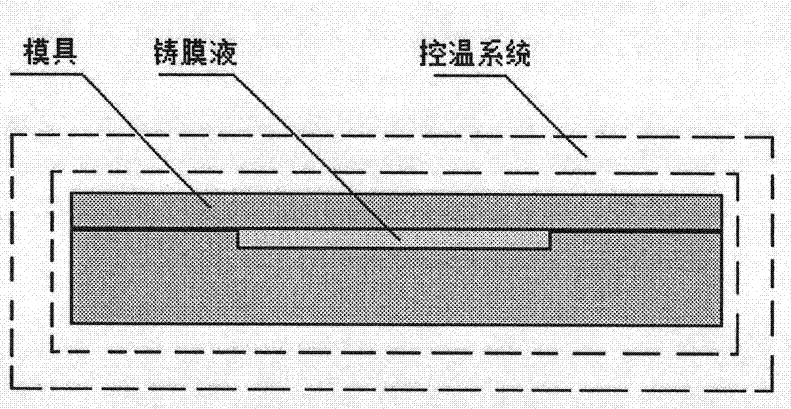

[0036] Step 2: Pour the casting solution evenly into the mold that has been preheated to 115°C (such as figure 1 (shown), the mold was cooled at room temperature, and after the casting solution solidified and separated into phases, the mold was disassembled and placed in water at 4°C for extraction for 10 minutes to obtain a polyvinylidene fluoride-based film.

[0037] S...

Embodiment 2

[0042] Step 1: Accurately weigh 4g polyvinyl alcohol, 16g polyvinylidene fluoride, 80g caprolactam, polyvinylidene fluoride vinyl / polyvinyl alcohol is 8: 2, polymer material mass fraction is 20%, polyvinyl alcohol, polyvinylidene Mix vinyl fluoride and caprolactam evenly and pour them into a 250ml beaker. The temperature of the oil bath used is 145°C. The heating process requires nitrogen protection. Heat for 1.5 hours to dissolve polyvinyl alcohol, polyvinylidene fluoride and caprolactam, and then stir the solution with an electric stirrer 2 hour, then leave it to stand to obtain the casting solution.

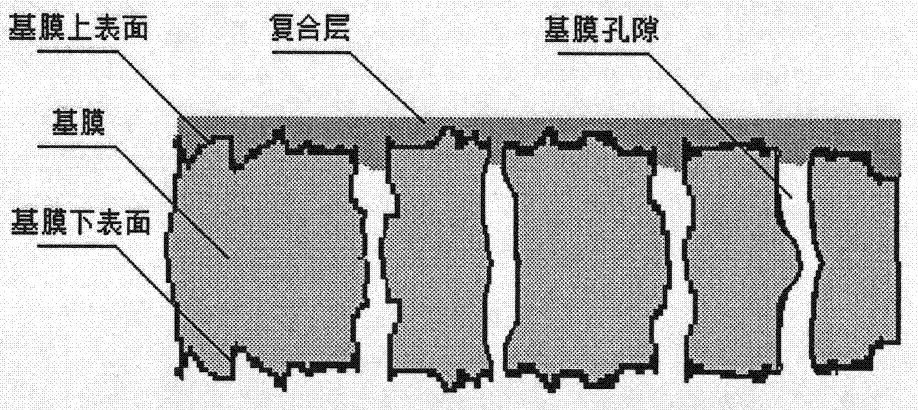

[0043] Step 2: Pour the casting solution evenly into the mold that has been preheated to 145°C (such as figure 1 (shown), place the mold at room temperature to cool down, and after the casting solution solidifies and separates into phases, the mold is disassembled and placed in water at 25°C for extraction for 20 minutes to obtain a polyvinylidene fluoride-based film (its morp...

Embodiment 3

[0049] Step 1: Accurately weigh 5g polyvinyl alcohol, 20g polyvinylidene fluoride, 75g caprolactam, polyvinylidene fluoride ethylene / polyvinyl alcohol is 8:2, polymer material mass fraction is 25%, polyvinyl alcohol, polyvinylidene Mix vinyl fluoride and caprolactam evenly and pour them into a 250ml beaker. The temperature of the oil bath used is 170°C. The heating process requires nitrogen protection. Heat for 2 hours to dissolve polyvinyl alcohol, polyvinylidene fluoride and caprolactam, and then stir the solution with an electric stirrer for 3.5 hour, then leave it to stand to obtain the casting solution.

[0050] Step 2: Pour the casting solution evenly into the mold that has been preheated to 170°C (such as figure 1 (shown), the mold was cooled at room temperature, and after the casting solution was solidified and separated into phases, the mold was disassembled and placed in water at 25°C for extraction for 30 minutes to obtain a polyvinylidene fluoride-based film.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com