A kind of antibacterial thin-layer composite film and preparation method thereof

The technology of composite membrane and antibacterial layer is applied in the field of antibacterial thin layer composite membrane and its preparation, which can solve the problems of loss of antibacterial inorganic nanoparticles, poor durability of antibacterial performance on the surface of the membrane, etc., and achieves strong antibacterial pollution performance and low production cost. , the effect of high salt interception rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

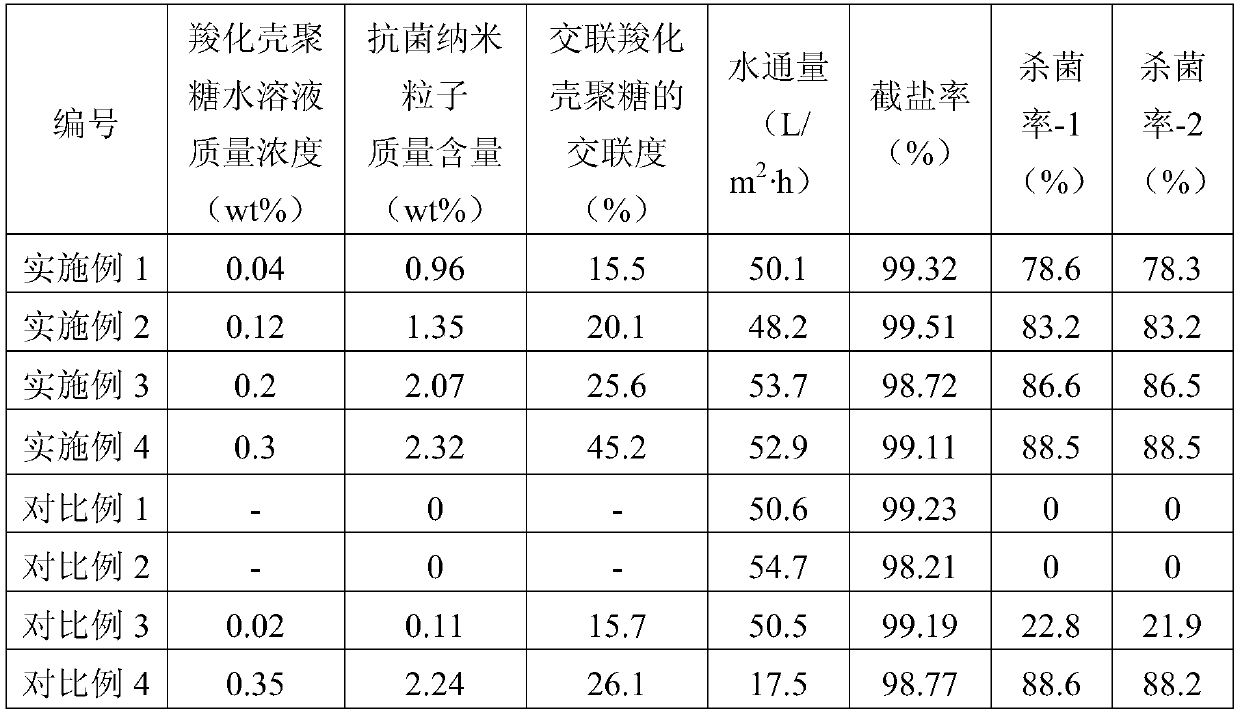

Examples

Embodiment 1

[0057] The carboxylated chitosan (the degree of carboxylation is 60%, the viscosity-average molecular weight is 80,000) aqueous solution that mass concentration is 0.04wt% is coated on the polyamide active layer surface of composite nanofiltration membrane (Dow Chemical NF90), after coating After covering the surface of the polyamide layer (i.e. the functional layer) with the covering liquid for 10 seconds, remove excess carboxylated chitosan solution on the surface of the polyamide layer, place it in an oven at 120° C. and dry it for 1 min before taking it out; the mass concentration is 2.5 wt % The copper chloride aqueous solution is in contact with the surface of the carboxylated chitosan of the composite nanofiltration membrane. After contacting for 5 minutes, the excess copper chloride solution is removed, and then the surface of the carboxylated chitosan treated with the copper chloride solution is compared with the mass concentration Contact with 0.05wt% glutaraldehyde a...

Embodiment 2

[0059] The carboxylated chitosan (the degree of carboxylation is 75%, the viscosity-average molecular weight is 120,000) aqueous solution that the mass concentration is 0.12wt% is coated on the polyamide active layer surface of composite nanofiltration membrane (Dow Chemical NF90), after coating After soaking the surface of the polyamide layer with the covering liquid for 20 seconds, remove excess carboxylated chitosan solution on the surface of the polyamide layer, place it in an oven at 100° C. for 3 minutes and take it out; Contact with the carboxylated chitosan surface of the composite nanofiltration membrane, after being in contact for 5 minutes, remove excess copper chloride solution, and then mix the carboxylated chitosan surface with a mass concentration of 0.1wt% through the copper chloride solution Contact the succinic dialdehyde aqueous solution for 3 minutes, then remove the excess succinic dialdehyde solution, and finally place it in an oven at 100° C. for 3 minute...

Embodiment 3

[0061] The carboxylated chitosan (the degree of carboxylation is 85%, the viscosity-average molecular weight is 200,000) aqueous solution that the mass concentration is 0.2wt% is coated on the polyamide active layer surface of composite nanofiltration membrane (Dow chemical NF270), after coating After soaking the surface of the polyamide layer with the covering liquid for 40 seconds, remove excess carboxylated chitosan solution on the surface of the polyamide layer, place it in an oven at 80° C. for 6 minutes and take it out; Contact with the carboxylated chitosan surface of the composite nanofiltration membrane, after being in contact for 5 minutes, remove excess copper chloride solution, and then mix the carboxylated chitosan surface with a mass concentration of 0.2wt% through the copper chloride solution The adipaldehyde solution was contacted for 6 minutes, and then the excess adipaldehyde solution was removed. Finally, it was placed in an oven at 80° C. for 6 minutes and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| cross-linking degree | aaaaa | aaaaa |

| degree of carboxylation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com