Synthesis method for preparing sulfonated polysulfurate (polyurethane) from polysulfurate (polyurethane) polymer

A technology of sulfonated polysulfuric acid and a synthesis method, which is applied in the synthesis field of preparing sulfonated polysulfate, can solve the problems of increased mass transfer resistance, increased production cost, waste of expensive protein and the like, and achieves the effect of good acid and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

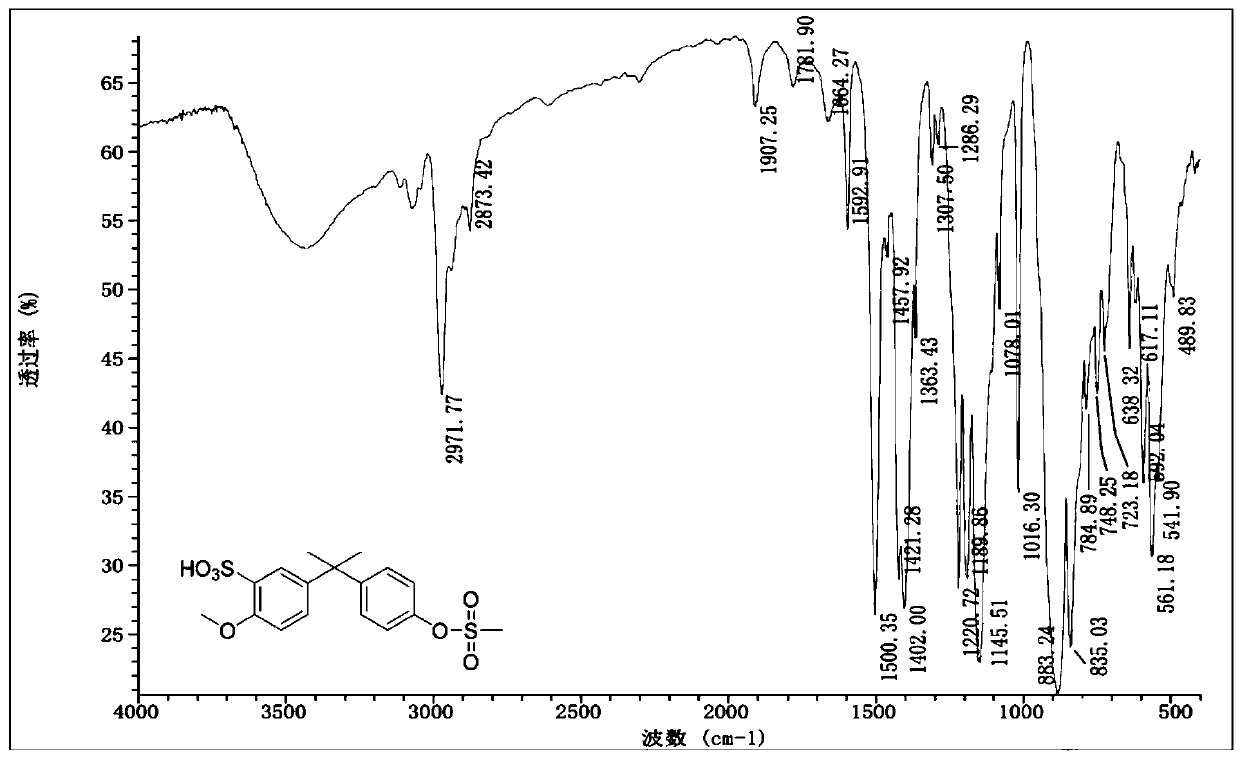

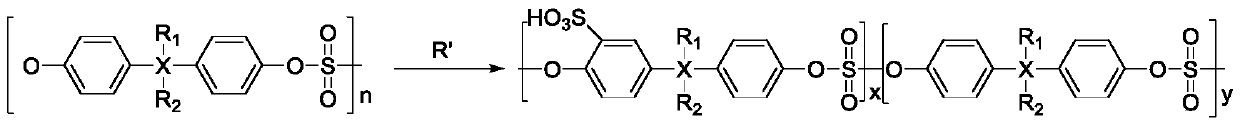

[0039] Synthesis of Sulfonated Polysulfate with Sulfonation Degree of 20%

[0040] Dissolve 10g of polymer in 50ml of N-methylpyrrolidone, add 10g (0.1mol) of concentrated sulfuric acid, a sulfonating agent, to the polysulfate system at room temperature and constant temperature, and stir for reaction. The reaction time is 4 hours. After the reaction The product was poured into water and precipitated to obtain 9.8 g of white solid sulfonated polysulfate polymer, the degree of sulfonation was 20%, and the yield was 93%. The indicators of the polymer are as follows:

[0041] Mn=40000, water contact angle 68°~70°, salt interception rate (NaCO 3 )=15%~17%.

[0042] Among the above-mentioned sulfonation reactions, when using concentrated sulfuric acid, chlorosulfonic acid, sulfur trioxide and other sulfonating reagents, the solvent is methylene dichloride, ethylene dichloride, chloroform, ethyl acetate, acetonitrile, toluene or dioxane, Sulfonated polysulfate compounds with simil...

Embodiment 2

[0044] Synthesis of Sulfonated Polysulfate with Sulfonation Degree 25%~30%

[0045] Dissolve 15g of polymer in 50ml of N-methylpyrrolidone, add 10g (0.1mol) of concentrated sulfuric acid, a sulfonating reagent, into the polysulfate system at room temperature and constant temperature, and stir for reaction. The reaction time is 6 hours. After the reaction The product was poured into water and precipitated to obtain 9.9 g of a white solid sulfonated polysulfate polymer with a sulfonation degree of 30% and a yield of 93%. The indicators of the polymer are as follows:

[0046] Mn=40000, water contact angle 55°~58°, salt interception rate (NaCO 3 )=20%~25%.

[0047] Among the above-mentioned sulfonation reactions, when using concentrated sulfuric acid, chlorosulfonic acid, sulfur trioxide and other sulfonating reagents, the solvent is methylene dichloride, ethylene dichloride, chloroform, ethyl acetate, acetonitrile, toluene or dioxane, Sulfonated polysulfate compounds with simi...

Embodiment 3

[0049] Heterogeneous Synthesis of Sulfonated Polysulfate with Sulfonation Degree 15%~20%

[0050] At room temperature and constant temperature, add 10 g (0.1 mol) of concentrated sulfuric acid, a sulfonating reagent, into 15 g of polysulfate powder system. The system is in the form of a paste, stirred and reacted. The reaction time is 4 hours. After the reaction, the product is poured into water to precipitate, and the obtained The product was 9.9 g of white solid sulfonated polysulfate polymer, the degree of sulfonation was 20%, and the yield was 94%. The indicators of the polymer are as follows:

[0051] Mn=40000, water contact angle 68°~70°, salt interception rate (NaCO 3 )=15%~17%.

[0052] Among the above-mentioned sulfonation reactions, when using concentrated sulfuric acid, chlorosulfonic acid, sulfur trioxide and other sulfonating reagents, the solvent is methylene dichloride, ethylene dichloride, chloroform, ethyl acetate, acetonitrile, toluene or dioxane, Sulfonat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com