Preparation method of high-performance cellulose triacetate forward osmosis membrane

A technology of triacetate fiber and forward osmosis membrane, which is applied in the field of materials science, can solve the problem of low permeation flux, achieve large permeation flux, improve mechanical properties, and simplify the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

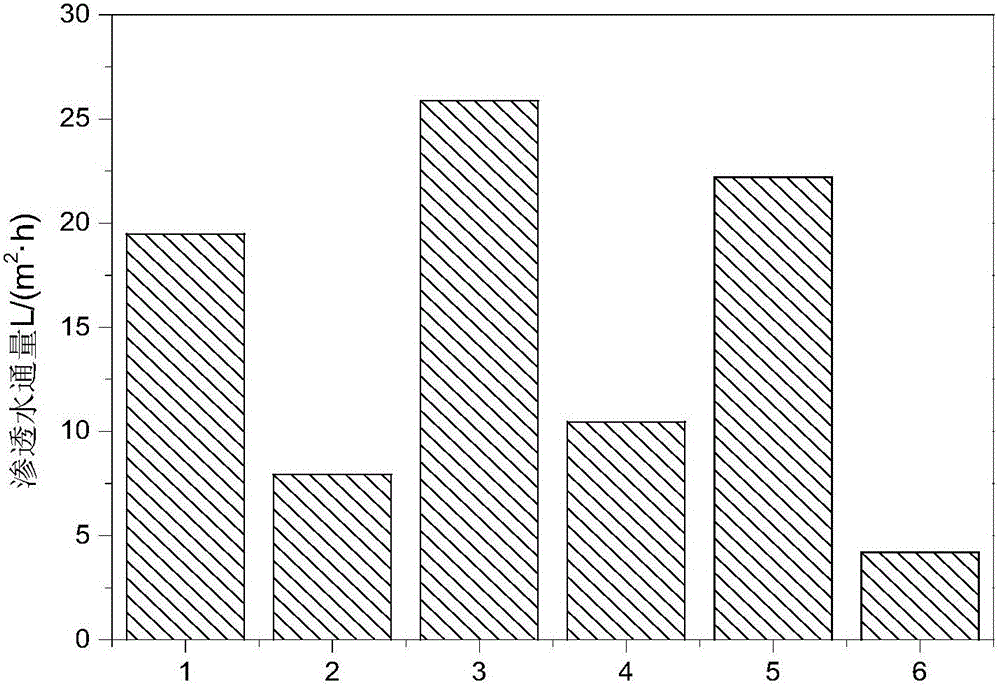

Embodiment 1

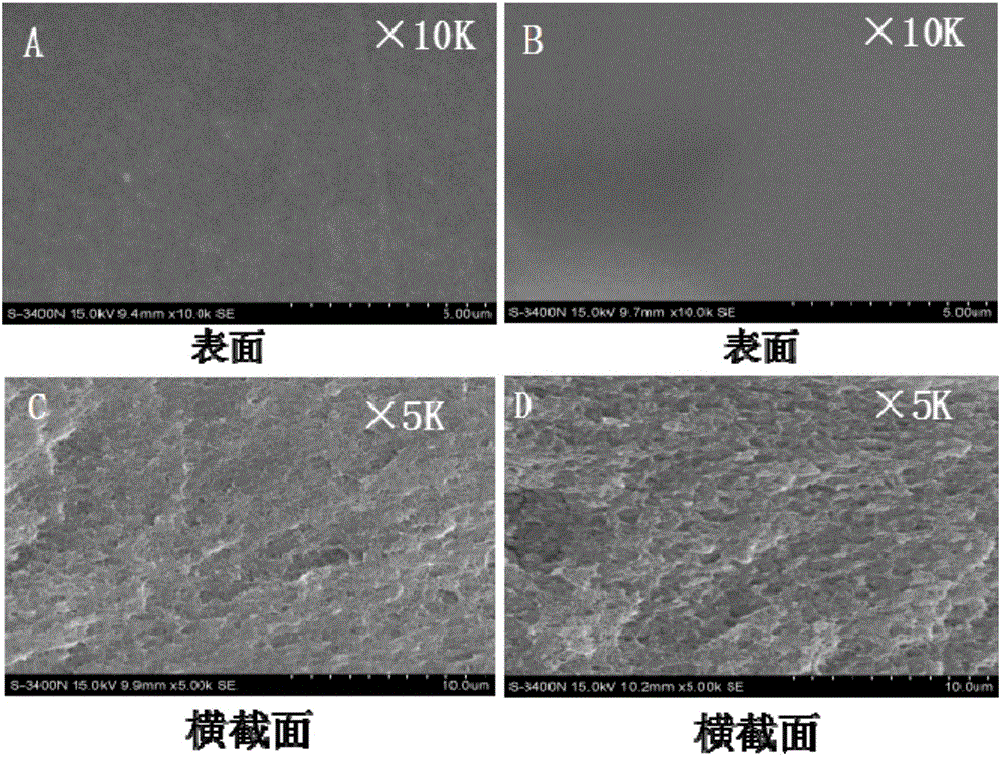

[0025] Add 1wt.% lactic acid to a binary mixed solvent of acetone and N-methylpyrrolidone, ultrasonicate for 10 minutes; make it fully mixed. Then add a total amount of 16wt.% triacetate fiber, control the temperature at 50°C, and mechanically stir for 24 hours to obtain the casting solution; after fully defoaming the obtained casting solution at 50°C, place a scraper knife with a certain gap in the Scratch the film on a glass plate; then, immerse the glass plate with a thin layer of casting solution in a gel bath at 25°C to form a phase-separated film, then soak it in deionized water for 7 days, take it out, and dry it naturally in the air to obtain triacetic acid Fiber forward osmosis membrane.

[0026] In the binary mixed solvent composed of acetone and N-methylpyrrolidone, acetone and N-methylpyrrolidone are based on the mass percentage of the casting solution, acetone is 18.0wt.%, and N-methylpyrrolidone is 65.0wt .%; The gel bath is pure water. The gap of the set docto...

Embodiment 2

[0029] Add 6.0wt.% lactic acid to the binary mixed solvent of acetone and N-methylpyrrolidone, and ultrasonicate for 10 minutes; make it fully mixed. Then add a total amount of 14.0wt.% triacetate fiber, control the temperature at 40°C, and mechanically stir for 24 hours to obtain the casting solution; after fully degassing the obtained casting solution at 40°C, set the scraping knife to a certain height, Scratch the film on a glass plate; then, immerse the glass plate with a thin layer of casting solution in a gel bath at 20°C to form a phase-separated film, then soak it in deionized water for 7 days, take it out, and dry it naturally in the air to obtain triacetic acid Fiber forward osmosis membrane.

[0030] In the binary mixed solvent composed of acetone and N-methylpyrrolidone, acetone and N-methylpyrrolidone are based on the mass percentage of the casting solution, acetone is 20.0wt.%, and N-methylpyrrolidone is 60.0wt .%; the gel bath is pure water; the gap of the set ...

Embodiment 3

[0033] Add 3.0wt.% lactic acid to the binary mixed solvent of acetone and N-methylpyrrolidone, and ultrasonicate for 10 minutes; make it fully mixed. Then add a total amount of 18.0wt.% triacetate fiber, control the temperature at 40°C, and mechanically stir for 24 hours to obtain the casting solution; after fully defoaming the obtained casting solution at 40°C, set the scraping knife to a certain height, Scratch the film on a glass plate; then, immerse the glass plate with a thin layer of casting solution in a gel bath at 25°C to form a phase-separated film, then soak it in deionized water for 7 days, take it out, and dry it naturally in the air to obtain triacetic acid Fiber forward osmosis membrane.

[0034]In the binary mixed solvent composed of acetone and N-methylpyrrolidone, acetone and N-methylpyrrolidone are based on the mass percentage of the casting solution, acetone is 15.0wt.%, and N-methylpyrrolidone is 64.0wt .%; the gel bath is pure water; the gap of the set d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com