Supercritical water gasification hydrogen production and heat absorption reactor for multi-disk solar heat-collecting coupling biomass

A technology of supercritical water gasification and solar heat concentrating, which is applied in hydrogen production, chemical industry, climate sustainability, etc. It can solve problems such as large temperature fluctuations, achieve small heat loss, high heat exchange efficiency, and realize heat transfer. loop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in further detail below in conjunction with accompanying drawing:

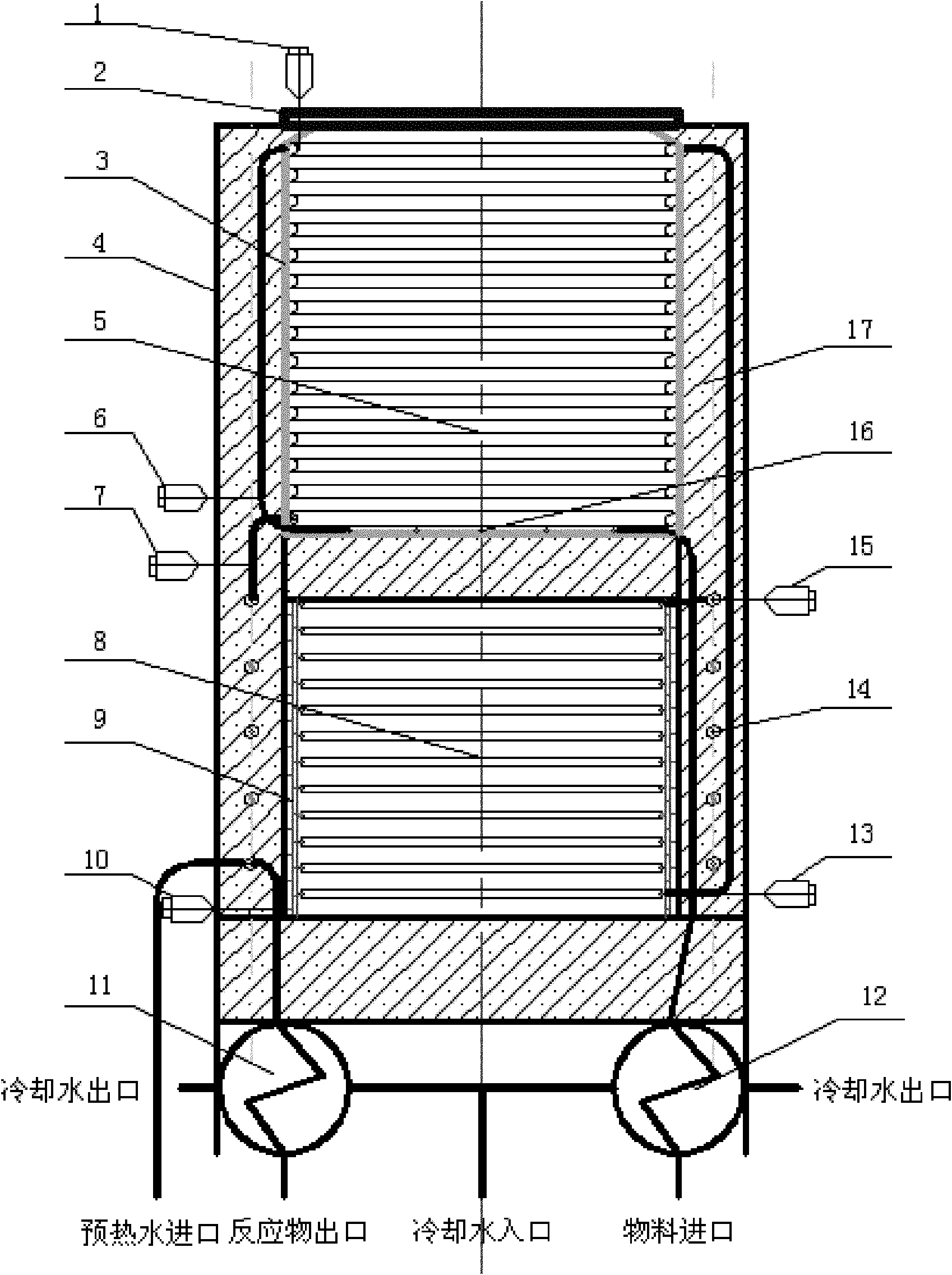

[0029] see figure 1, the present invention multi-disc solar heat concentrating coupled biomass supercritical water gasification hydrogen production endothermic reactor mainly includes cavity solar absorption reactor 4 and first and second coolers 11 and 12 . The chamber type solar energy absorption reactor 4 is composed of an endothermic reaction chamber at the upper part and a preheating water heating chamber at the lower part, and an insulating layer 17 is provided on the inner wall of the endothermic reaction chamber and the preheating water heating chamber. The upper opening of the endothermic reaction chamber (i.e. the entrance window) is sealed by quartz glass 2. In a preferred embodiment of the present invention, what the quartz glass 2 adopts is JGS3 infrared optical quartz glass with good light transmission performance, which can greatly avoid The convective ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solar absorptance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com