Sulfur resource recovery method and device making incineration, resolution, charcoal head reduction coordinated

A technology of resource recovery and sulfur recovery, which is applied in the field of air pollutant control and resource utilization, can solve the problems of difficult storage and transportation of sulfuric acid, and small application range, and achieve broad market application prospects, high-efficiency regeneration, and sulfur resource recovery. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

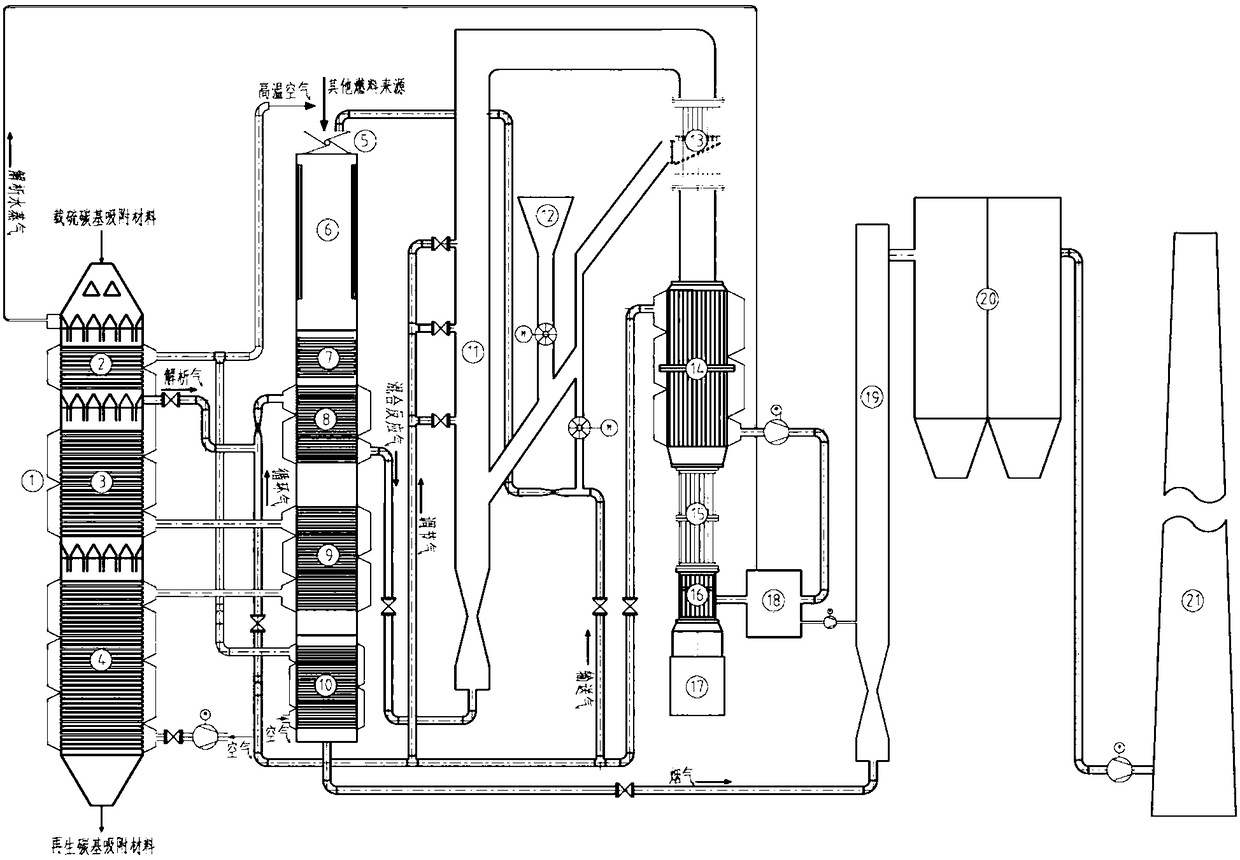

[0079] Such as figure 1 As shown, the desorption tower 1 includes a vertical tower body, and the tower is divided into a preheating section 2, a desorption section 3 and a cooling section 4, and heat exchange pipes are arranged horizontally in each section. The sulfur-loaded carbon-based adsorbent enters the tower from the upper part of the desorption tower 1, and successively passes through the space between the preheating section 2, desorption section 3, cooling section 4 and their respective internal heat exchange pipes. The incinerator 6 includes a vertical furnace body with a burner 5 on the top of the furnace. The incineration flue gas passes through the space between the rear heating surface shell and the heat exchange pipe, the acid gas removal tower 19, the dust collector 20 and the chimney 21 in sequence. , the conveying power is provided by the induced draft fan, and the rear heating surface includes an economizer 7, a mixed reaction gas heater 8, a secondary air he...

Embodiment 2

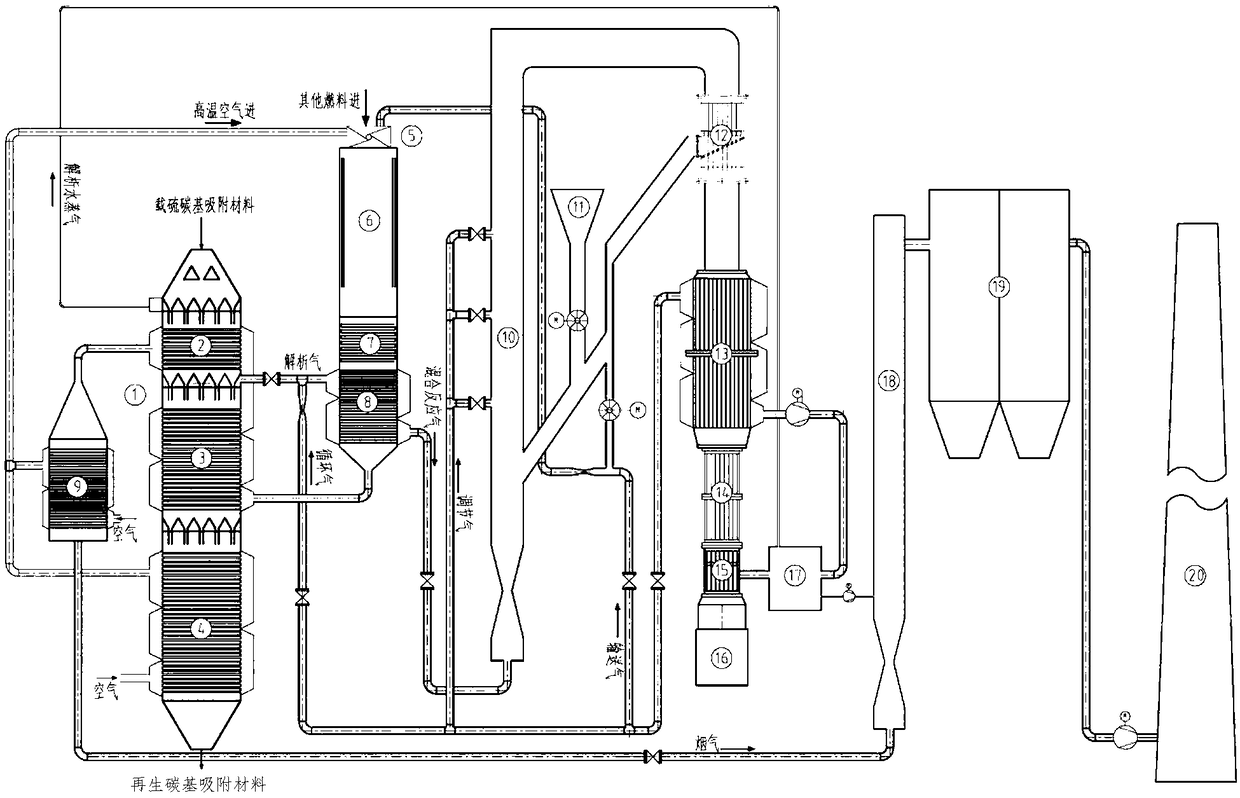

[0092] Such as figure 2As shown: the desorption tower 1 includes a vertical tower body, and the tower is divided into a preheating section 2, a desorption section 3 and a cooling section 4, and heat exchange pipes are arranged horizontally in each section. The sulfur-loaded carbon-based adsorbent enters the tower from the upper part of the desorption tower 1, and successively passes through the space between the preheating section 2, desorption section 3, cooling section 4 and their respective internal heat exchange pipes. The incinerator 6 includes a vertical furnace body, and a burner 5 is installed on the top of the furnace. The incineration flue gas passes through the space between the rear heating surface shell and the heat exchange pipe, the internal space of the analysis section 3 heat exchange tubes, and the preheating section. 2 The inner space of the heat exchange tubes, the space between the shell of the air heater 9 and the heat exchange pipes, the acid gas remova...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com