Heat reservoir based on phase-change material and movable heat storage device provided with heat reservoir

A technology of phase change materials and heat storage devices, which is applied in the direction of heat exchangers, indirect heat exchangers, heat storage equipment, etc., can solve the difficulties of recovery of phase change separation heat storage devices, troublesome installation or disassembly of heat storage devices, hydrogen Barium oxide has high toxicity and other problems, so as to avoid excessive heat loss, good heat insulation effect, and good heat preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0086] Manufacture Example 1 Manufacture of heat exchangers with different structures

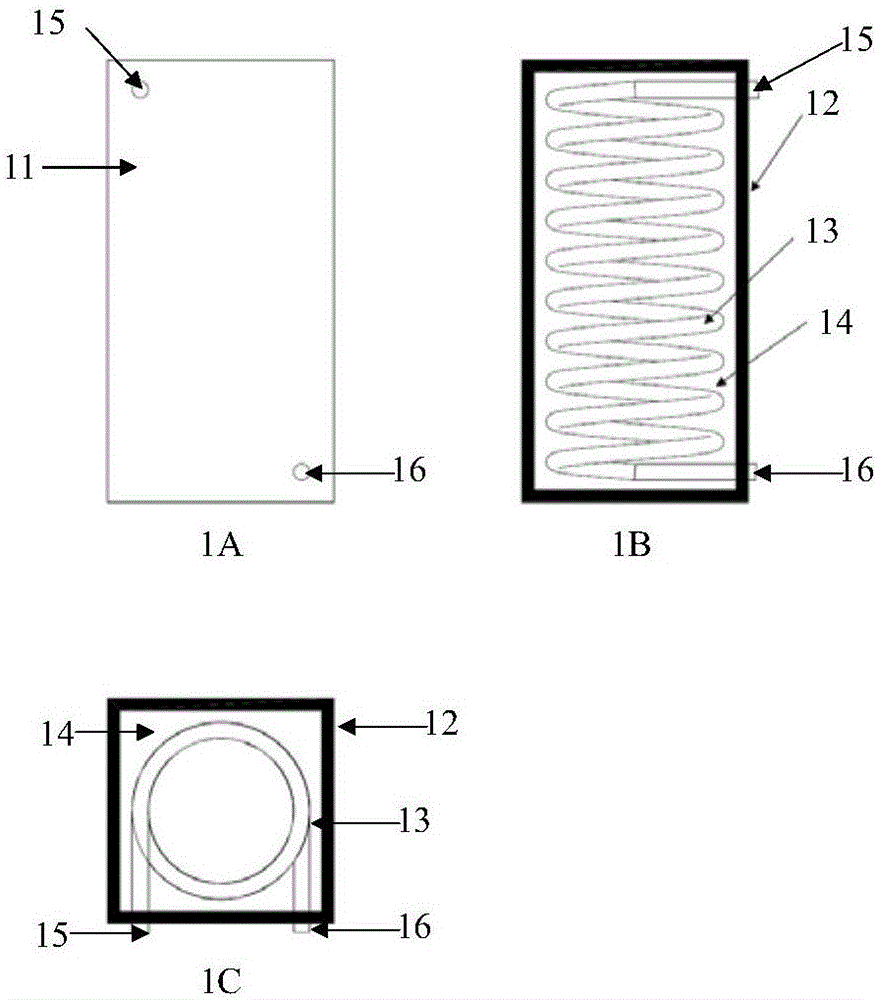

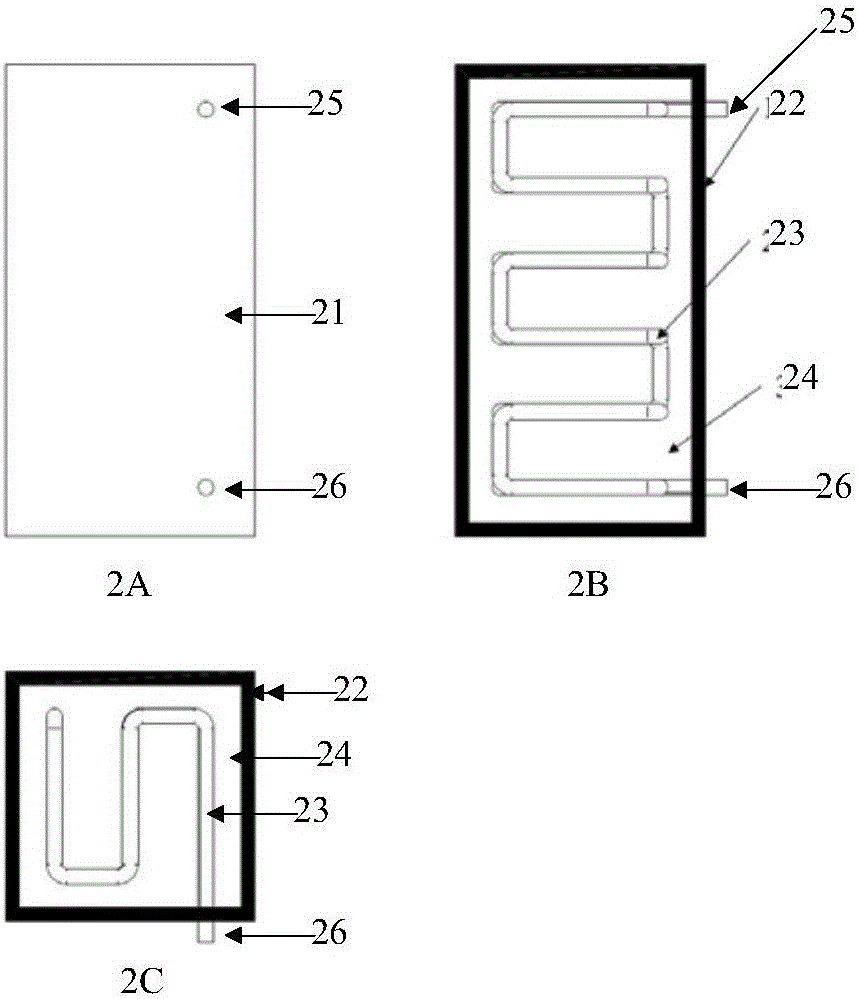

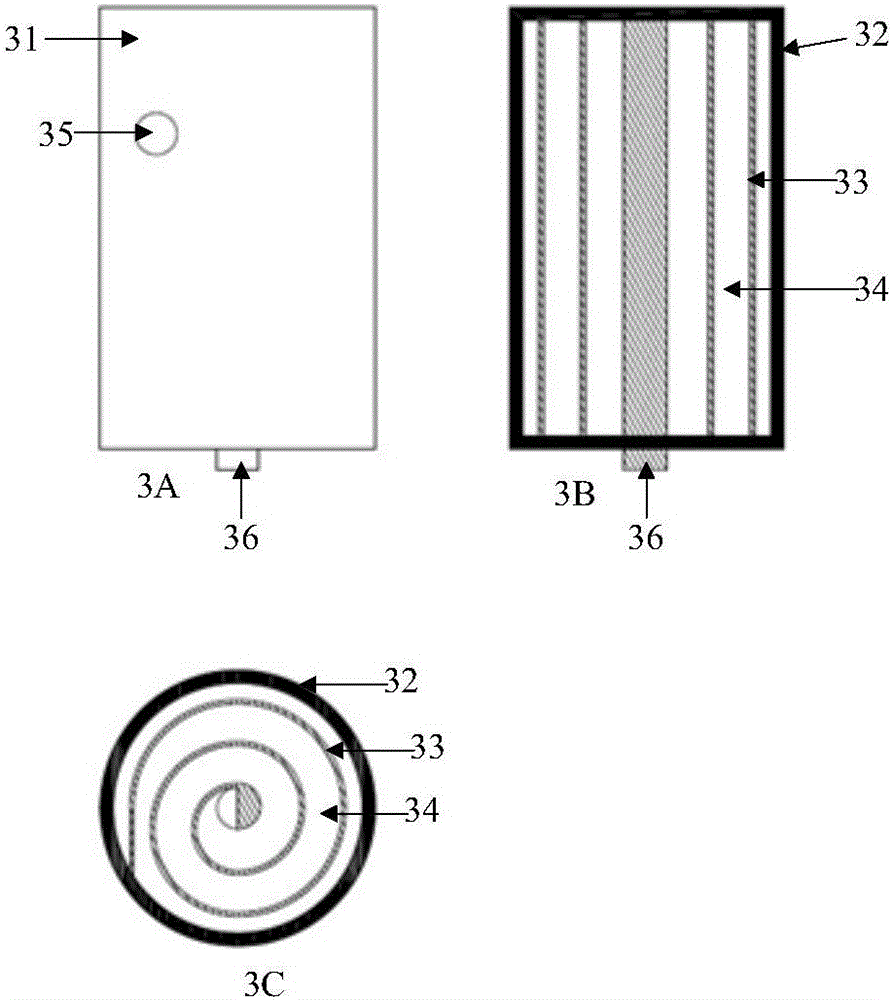

[0087] Design and manufacture respectively as figure 1 , 2 Three kinds of heat exchangers of the coil tube, the return tube and the spiral plate of the heat storage shown in 3, they have the following structural parameters:

[0088] Table 1: Structural parameters of three heat exchangers

[0089]

[0090] The heat exchanger described above was tested using a thermally conductive phase change material. The performance parameters of the material are as follows: the phase transition point is 120°C; the latent heat of phase transition is 250kJ / kg; the thermal conductivity at room temperature is 5W / mK; the density is 1000kg / m 3 ; Specific heat at constant pressure is 2kJ / kgK.

[0091] It is found through experiments that the heat storage performance of the spiral tube heat exchanger or the spiral plate heat exchanger is relatively better, and the phase change material in the heat storage ...

Embodiment 1

[0102] The exhaust gas temperature of a thermal power plant boiler is 220-250°C, the pressure is 0.6MPa, and the flow rate is 8000m 3 / h~9000m 3 / h. The heat exchanger of the mobile energy storage device of the present invention has a spiral plate structure, and erythritol with a melting point of 120°C is selected as the phase change material, and expanded graphite is used as the thermally conductive filler, and the thermally conductive phase change material is composed of erythritol and thermally conductive filler. Formed, the mass percentage of the thermally conductive filler in the thermally conductive phase change material is 10%, the phase change latent heat of the thermally conductive phase change material is 250kJ / kg, and the thermal conductivity is (10W / m·K); the shell sandwich structure contains The insulation material is airgel insulation material, and the thickness of the sandwich structure is 30mm. Using the mobile heat storage device of the present invention, th...

Embodiment 2-6

[0104] Except the content shown in the following table, it carried out in the same manner as Example 1.

[0105]

[0106]

[0107] It can be seen from the results in the table that the mobile heat storage device of the present invention has high heat storage efficiency and low heat transportation loss.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com