Method for synergistically realizing efficient removal of PM2.5/SO3 in high-moisture flue gas and zero water consumption in wet desulphurization

A wet desulfurization and high-moisture technology, applied in the field of dust removal, can solve the problems of high operating cost and complex equipment, and achieve the effects of suppressing evaporation, simple process, and deep utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

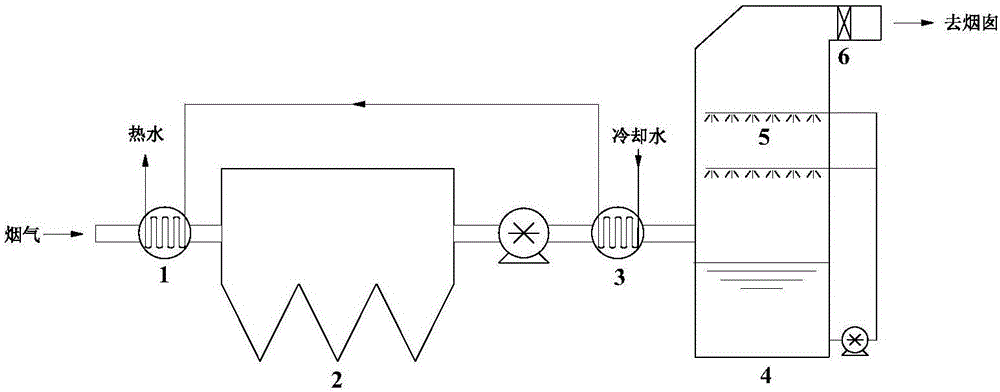

[0033] Such asfigure 1 As shown, a synergy of the present invention realizes PM in high-moisture flue gas 2.5 / SO 3 The method of high-efficiency desulfurization and wet desulfurization with zero water consumption mainly consists of low-temperature heat exchanger 1, electrostatic precipitator 2, low-low temperature heat exchanger 3, desulfurization tower 4, desulfurization liquid spray layer 5, and mist eliminator 6. The low-temperature heat exchanger 1 is set at the inlet flue of the electrostatic precipitator 2, and the low-low temperature heat exchanger 3 is set between the flue gas outlet of the electrostatic precipitator 2 and the flue gas inlet of the desulfurization tower 4; the cooling water of the low-temperature heat exchanger 1 comes from The cooling water in the low and low temperature heat exchanger 3 is discharged. The desulfurization tower 4 can adopt tower types such as spray tower, swirl plate tower, packed tower, turbulent ball tower, etc. The tower is provi...

Embodiment 2

[0036] The flue gas is produced by a fully automatic coal-fired boiler with a flue gas volume of 350Nm 3 / h, supplemented by an aerosol generator, SO 3 Add appropriate amount of coal-fired fly ash, SO 3 , water vapor, so that the dust concentration in the coal-fired flue gas is 3240mg / m 3 , in which the concentration of fine particles is 162mg / m 3 , SO 3 The concentration is 39mg / m 3 , the water vapor volume fraction is 14.35%. A low-temperature heat exchanger, an electric dust collector, a booster fan, a low-low temperature heat exchanger, and a limestone-gypsum flue gas desulfurization tower are arranged in sequence along the flue gas flow direction. The electrostatic precipitator has a three-electric field structure, the cathode is a conventional acupuncture electrode, and the distance between the plates is 0.30m. The heat exchange tube of the low temperature heat exchanger is made of finned tube and ND corrosion-resistant steel. The heat exchange tubes of the low an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com