Patents

Literature

37results about How to "Realize deep utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

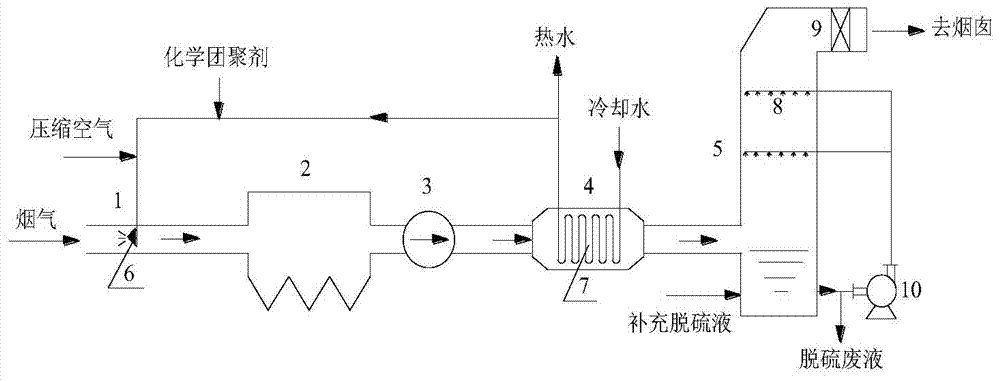

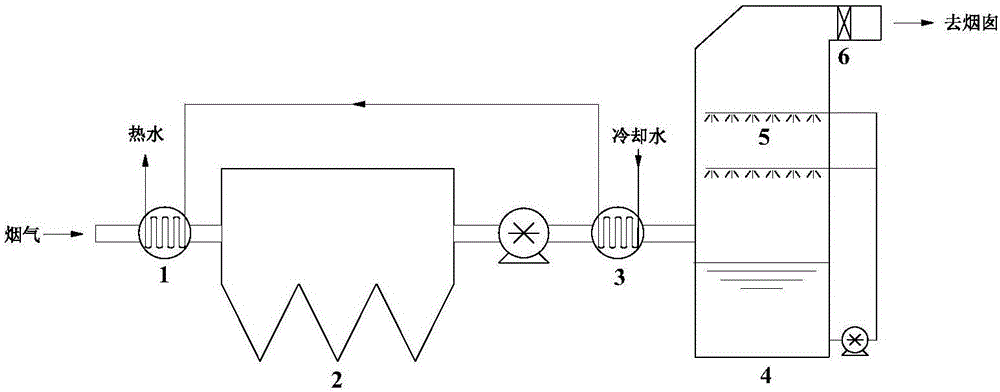

Method and device for cooperatively enhancing PM2.5 (Particulate Matter 2.5) removal and smoke afterheat deep utilization

ActiveCN103868087APromote reunionReduce dust specific resistanceExternal electric electrostatic seperatorFeed-water heatersLiquid temperatureFlue-gas desulfurization

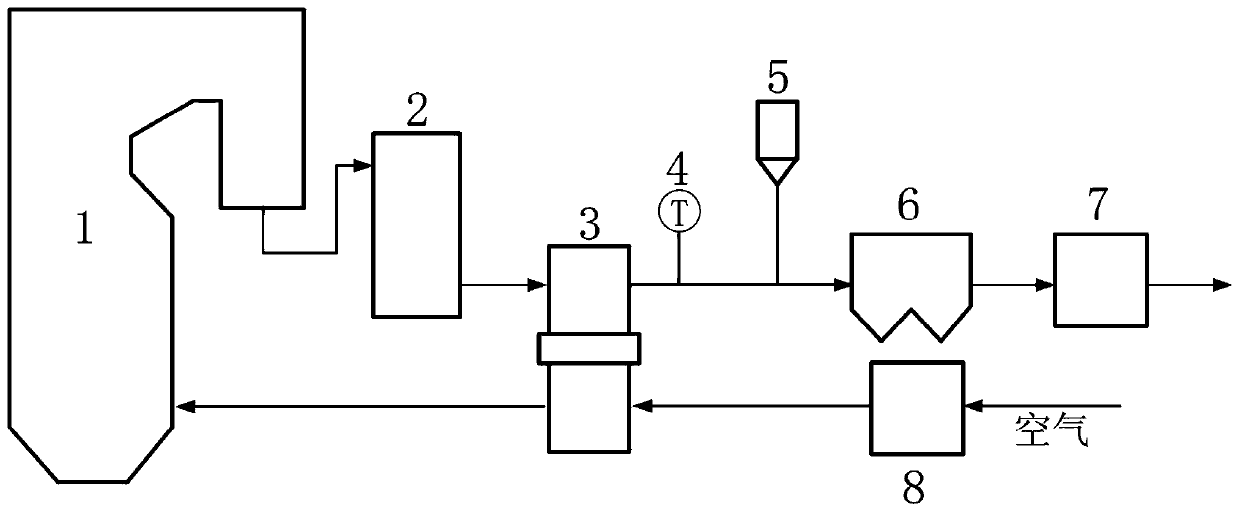

The invention relates to a method and a device for cooperatively enhancing PM2.5 (Particulate Matter 2.5) removal and smoke afterheat deep utilization. The device is composed of a smoke humidifying device, an electric dust remover, a low-temperature coal economizer and a wet desulphurization tower. The method comprises the following steps: before smoke enters the electric dust remover, spraying atomized hot water to carry out humidifying and tempering treatment; enhancing the PM2.5 capturing of the electric dust remover and improving the moisture content of the smoke; providing the atomized hot water by the low-temperature coal economizer; arranging the low-temperature coal economizer between the electric dust remover and the desulphurization tower to recycle the sensible heat released by cooling the smoke to obtain the smoke with high relative humidity; then adjusting an inlet gas-liquid temperature difference and a desulphurization liquid-gas ratio of the subsequent wet desulphurization tower to enable the smoke with the high relative humidity in the desulphurization tower to be over-saturated in a desulphurization and washing process; and carrying out nucleation condensation on over-saturated water steam on the surface of PM2.5 so as to enable the granularity of the PM2.5 to grow and be captured. According to the method and the device, the capturing effect on the PM2.5 by the electric dust remover and a wet smoke desulphurization system can be enhanced and the smoke afterheat can also be recycled.

Owner:SOUTHEAST UNIV

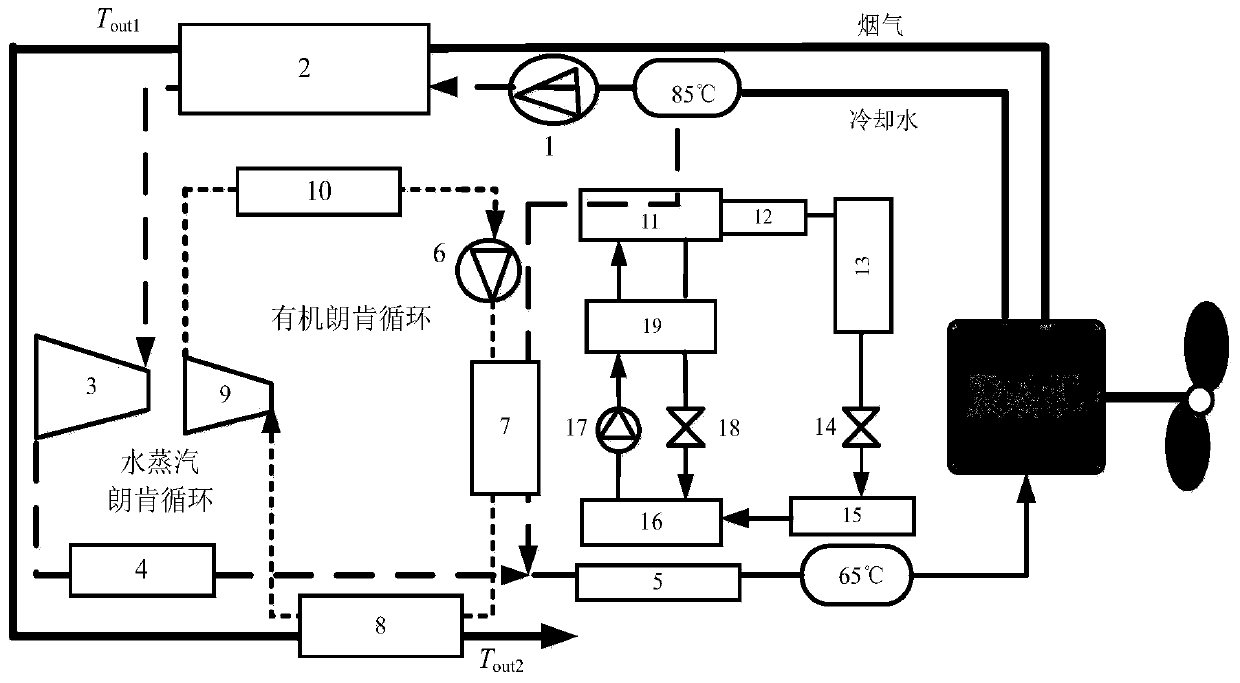

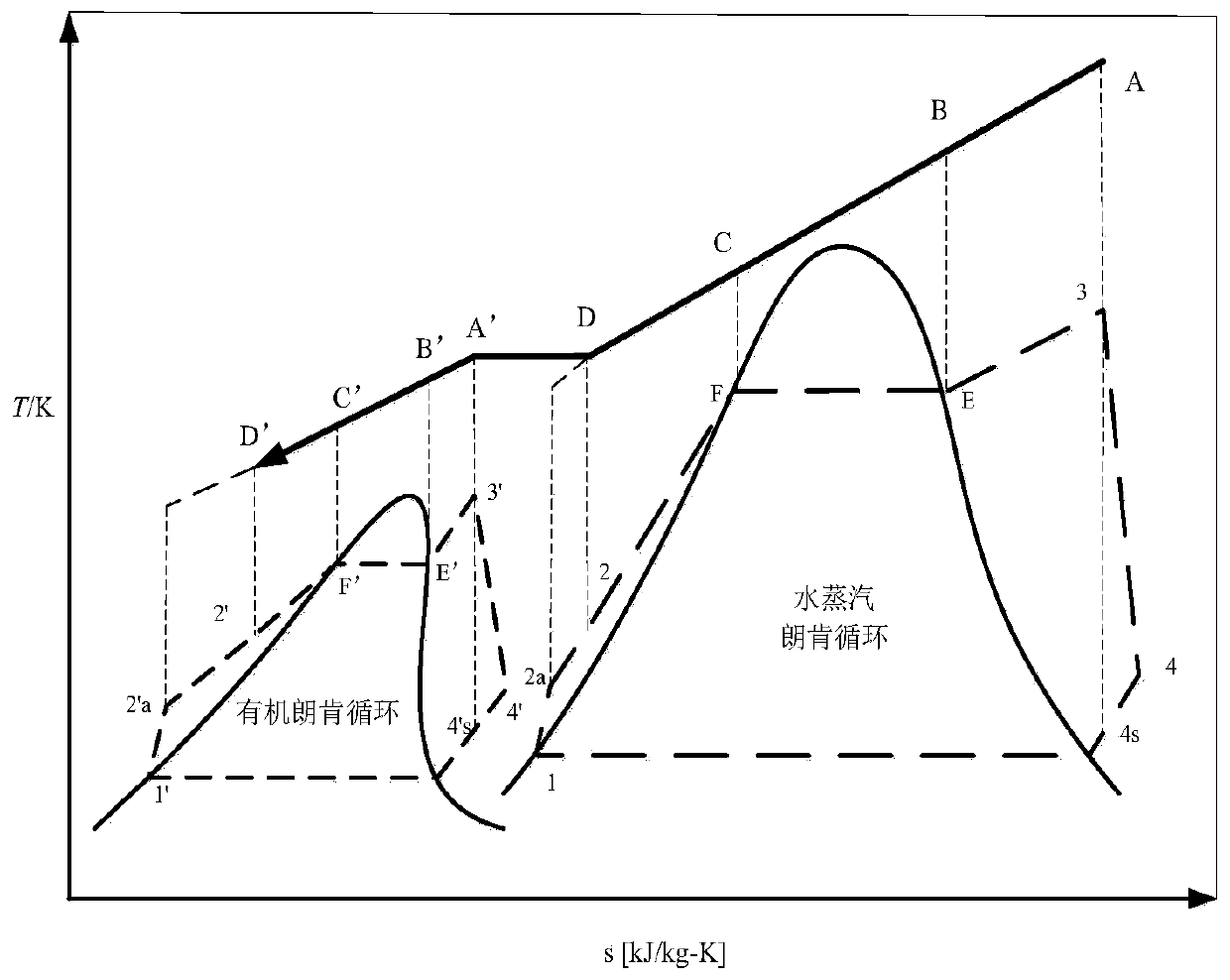

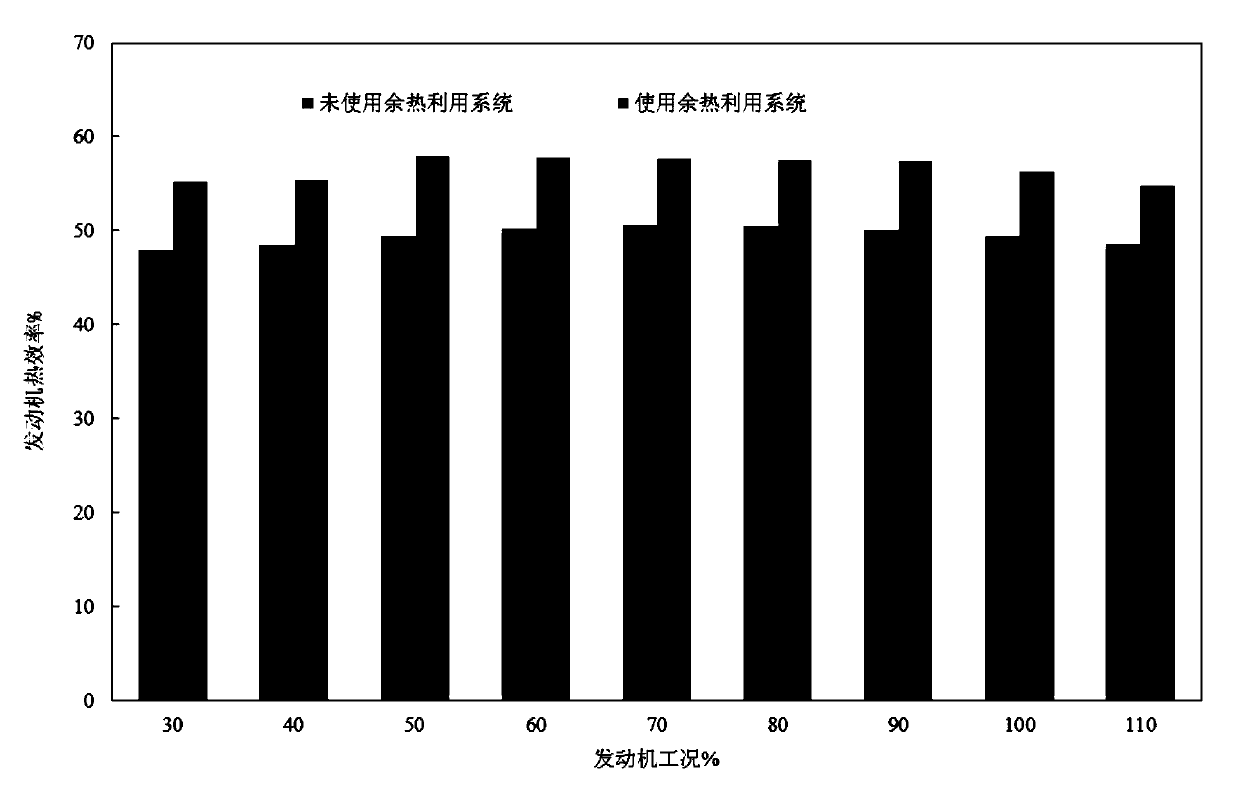

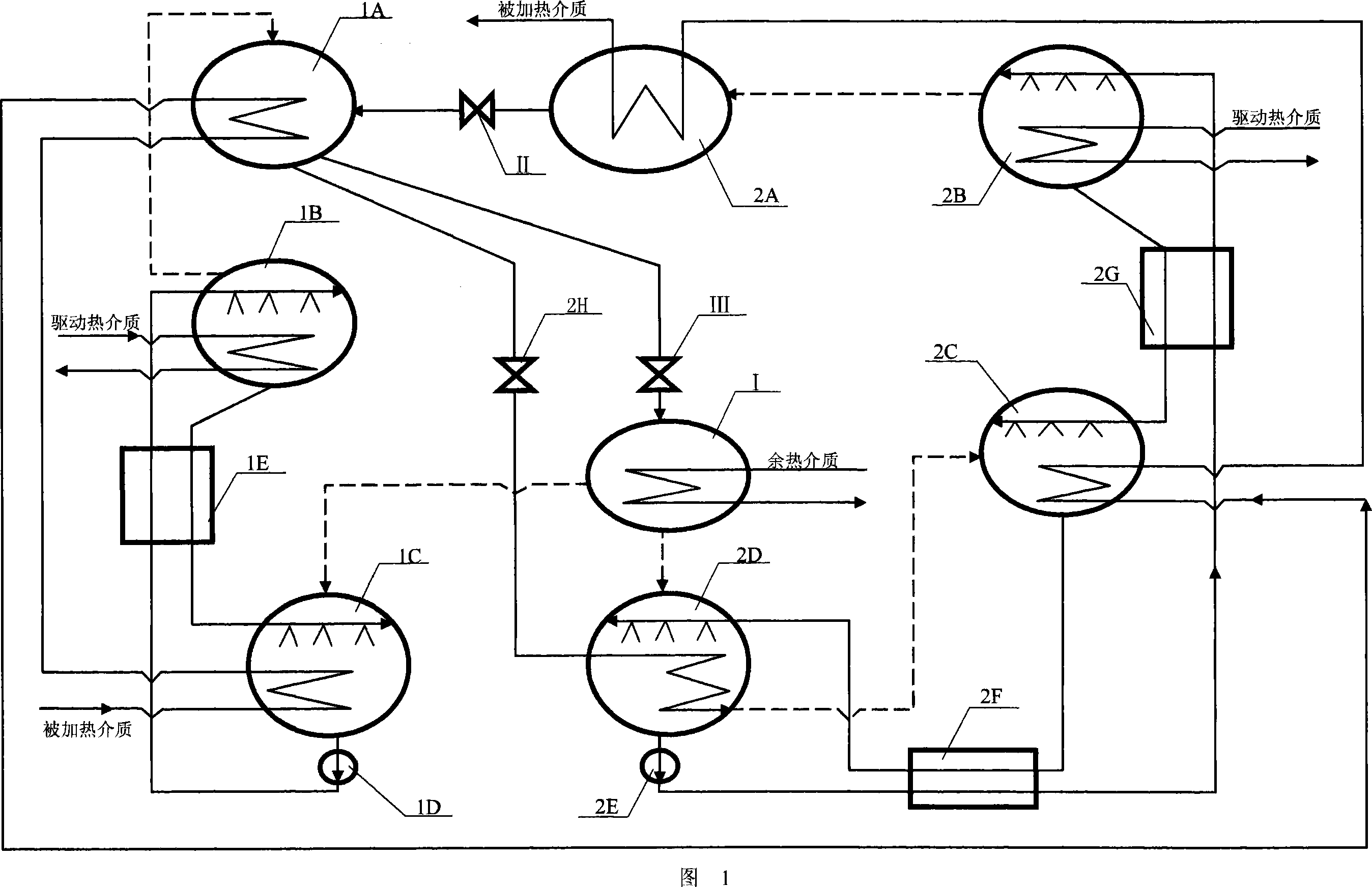

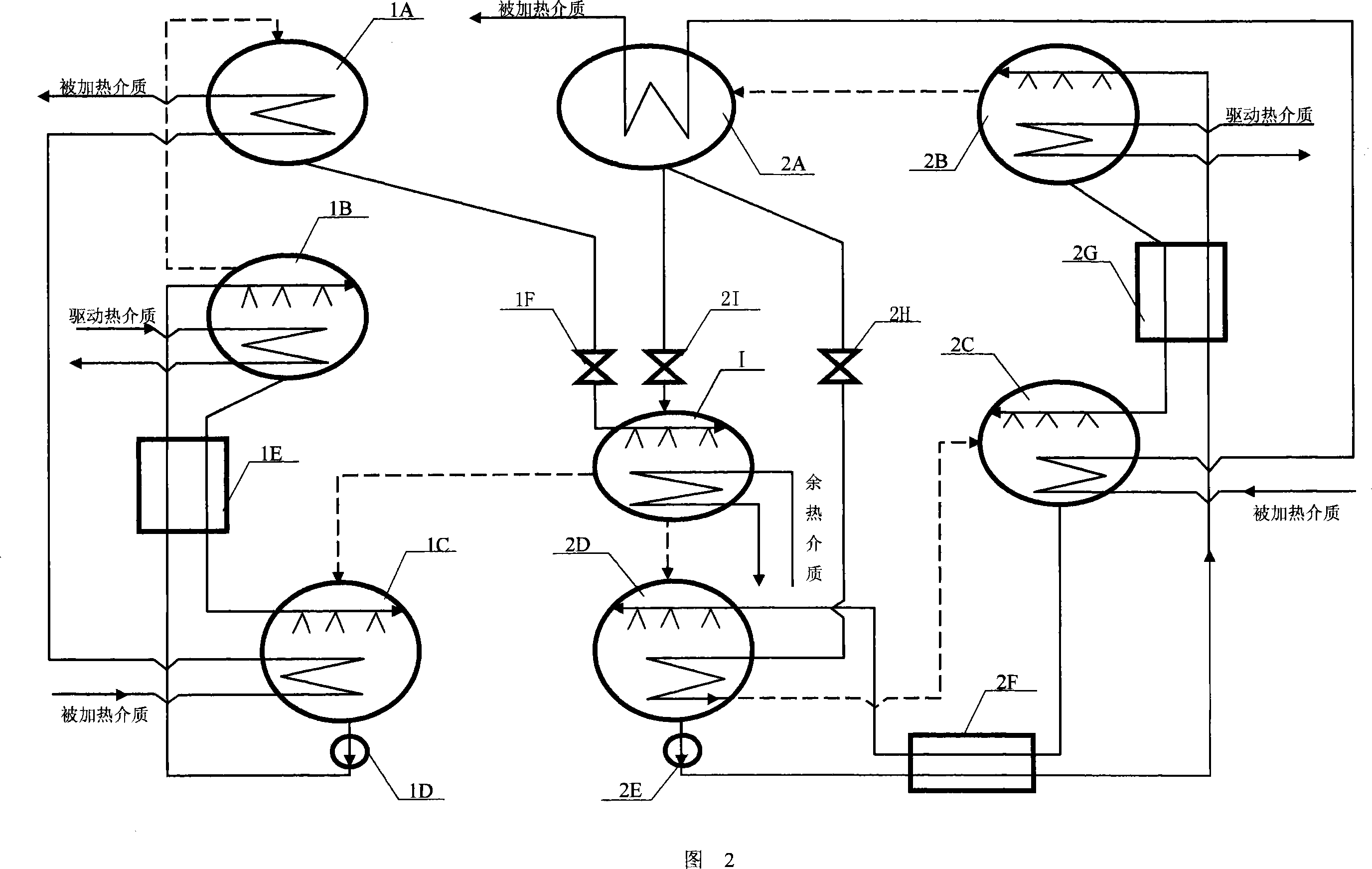

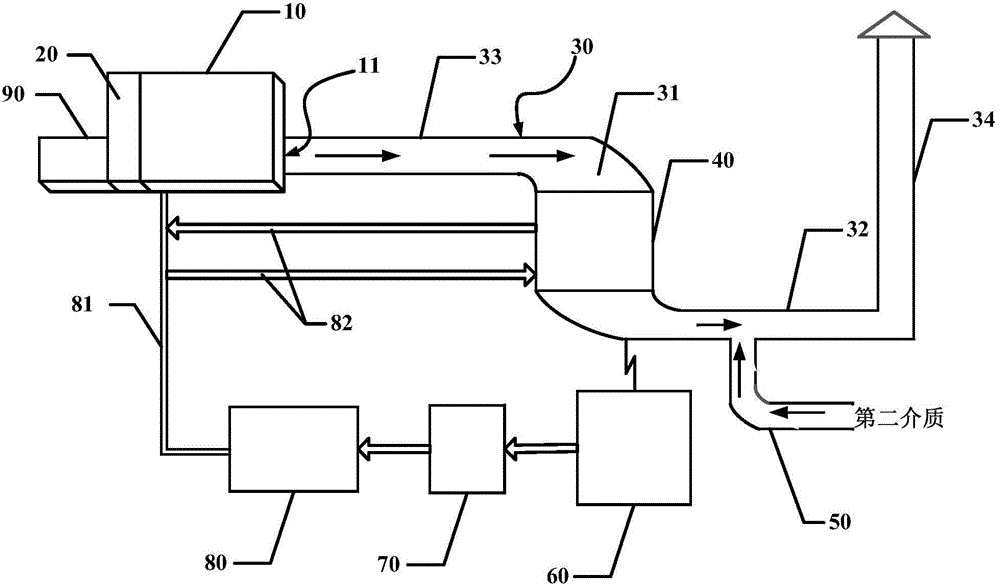

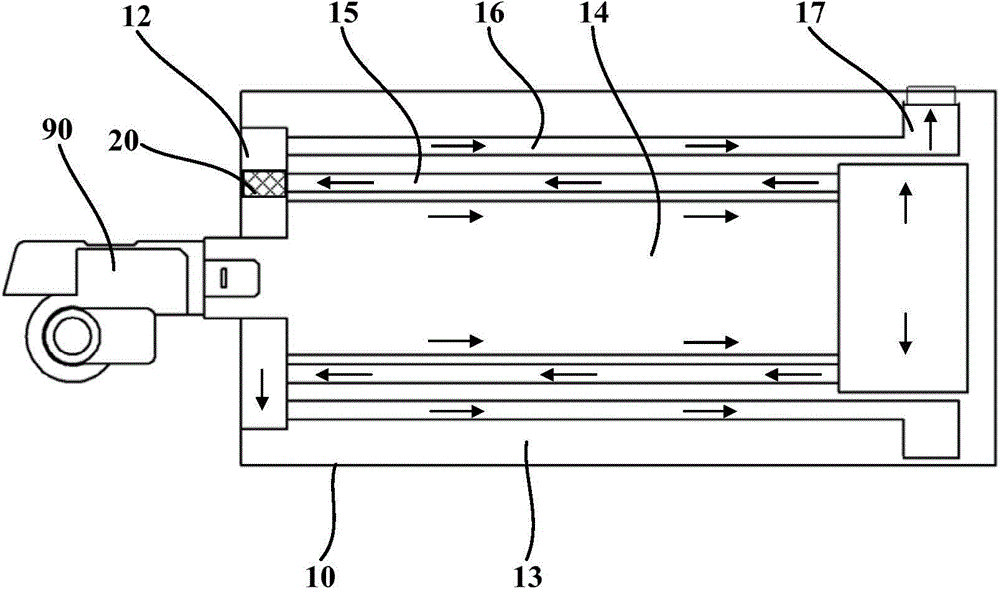

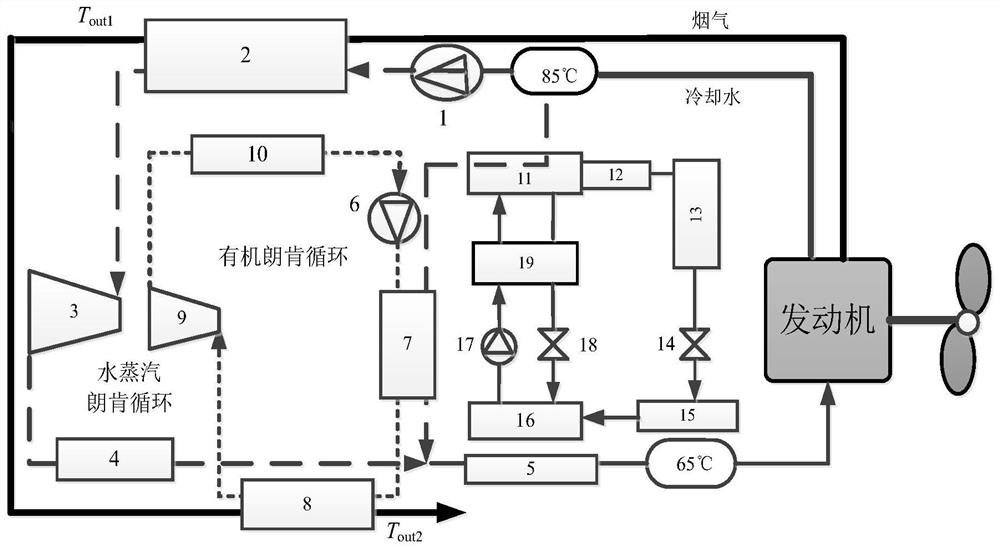

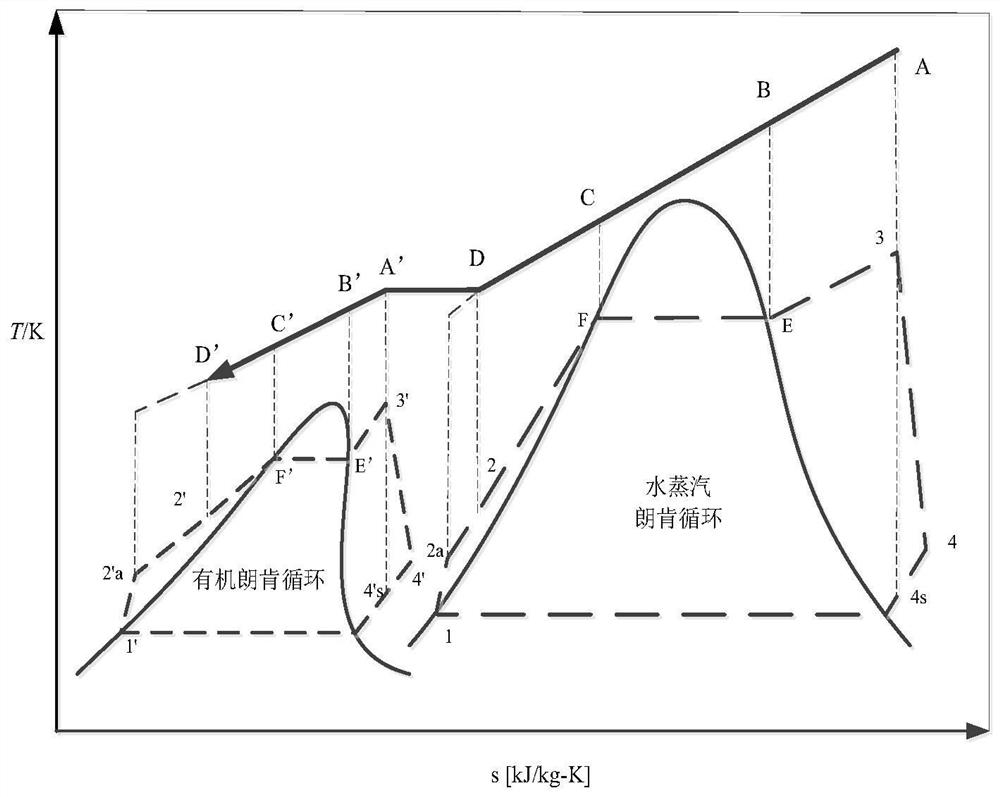

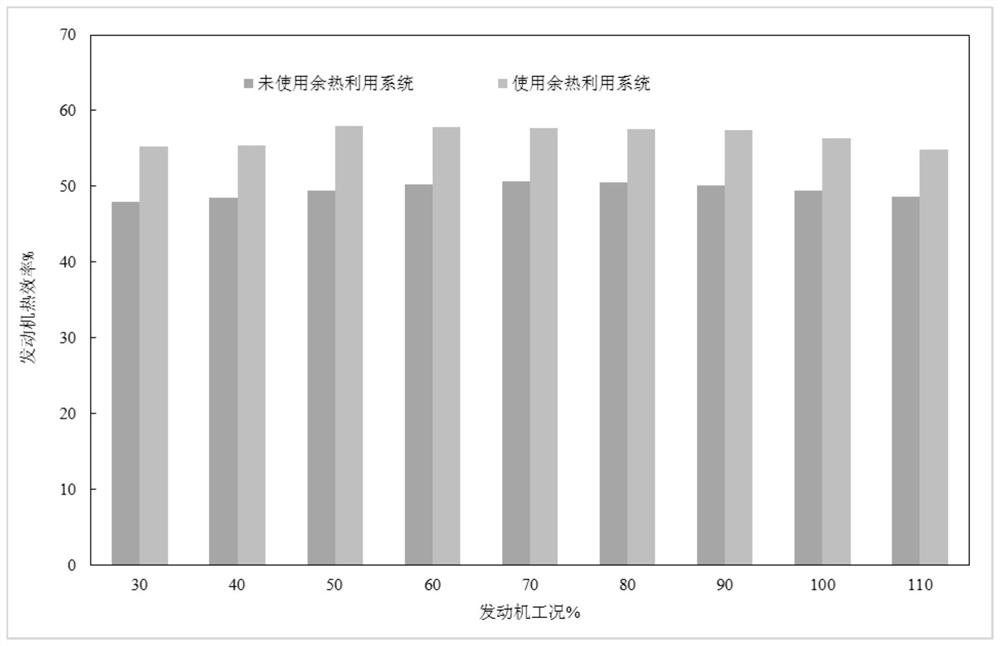

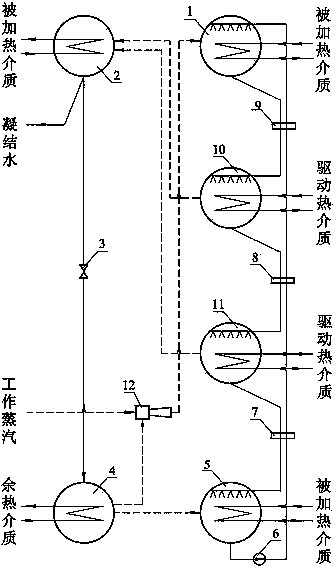

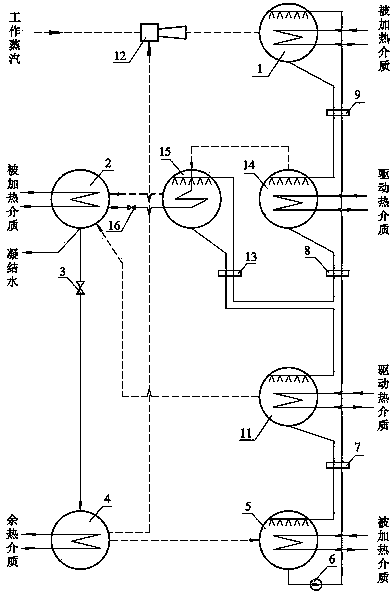

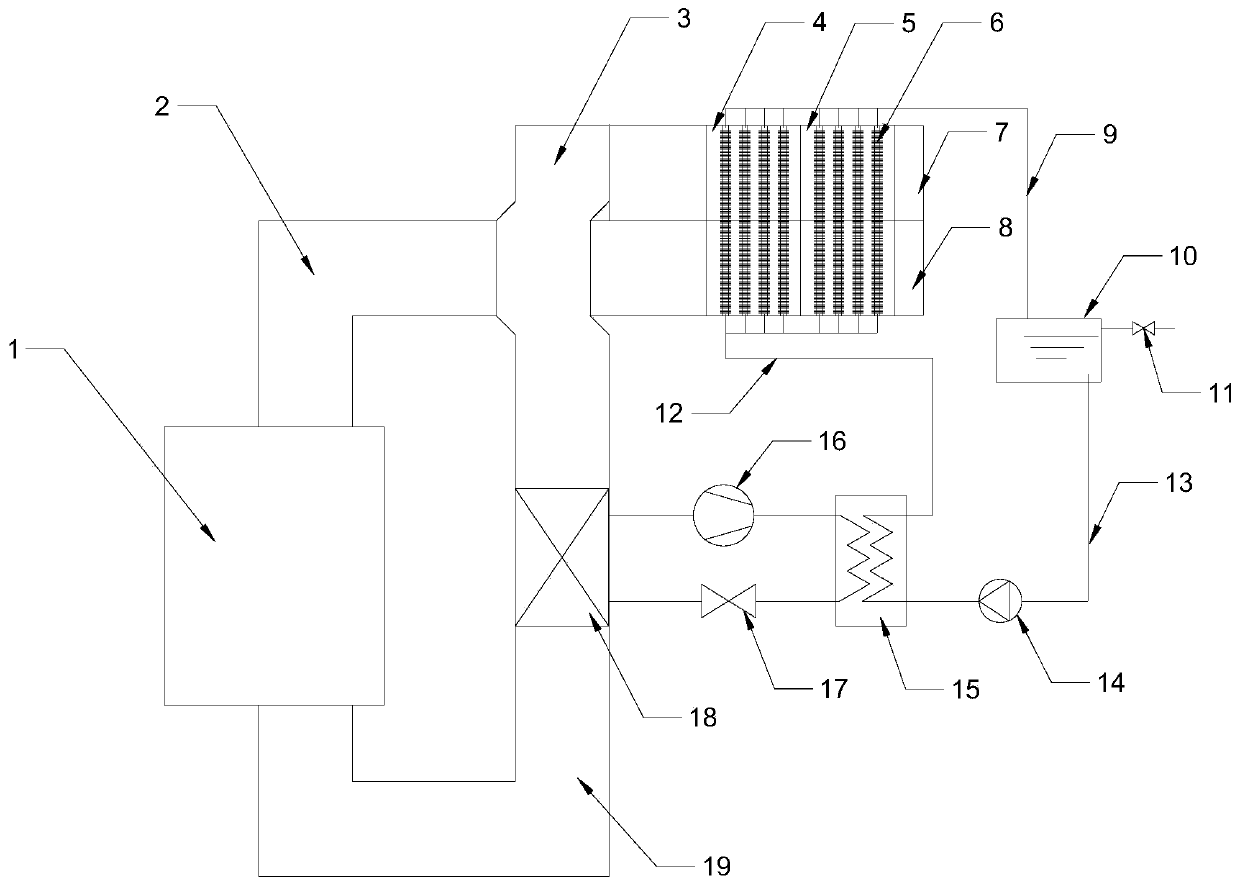

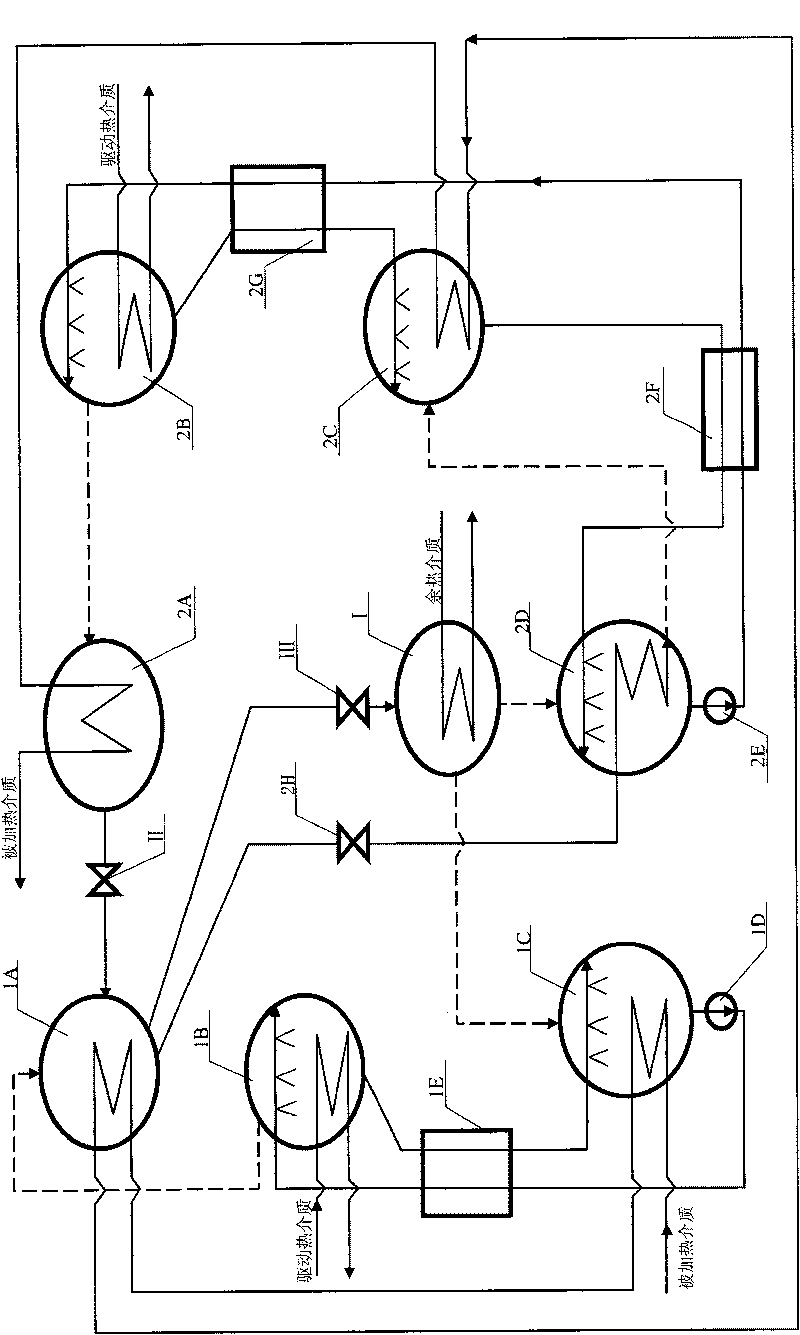

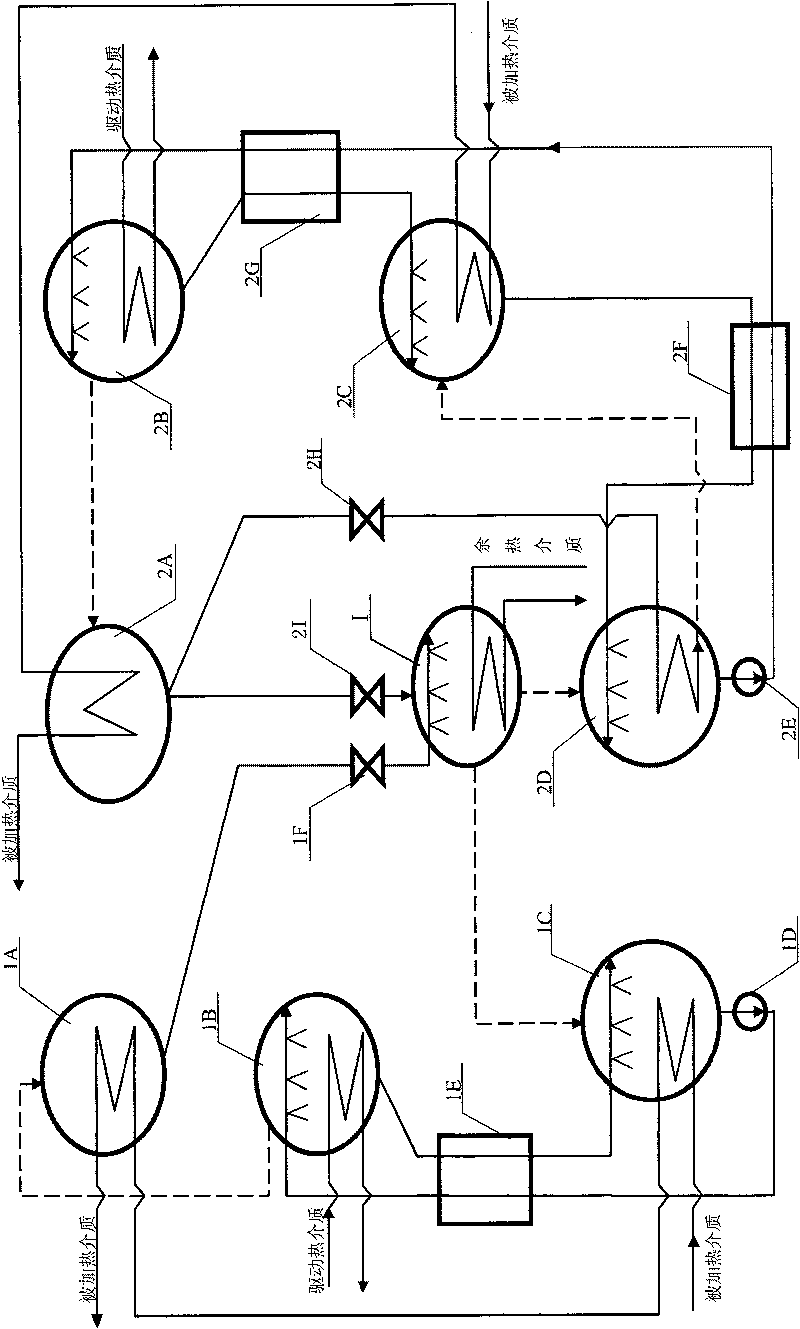

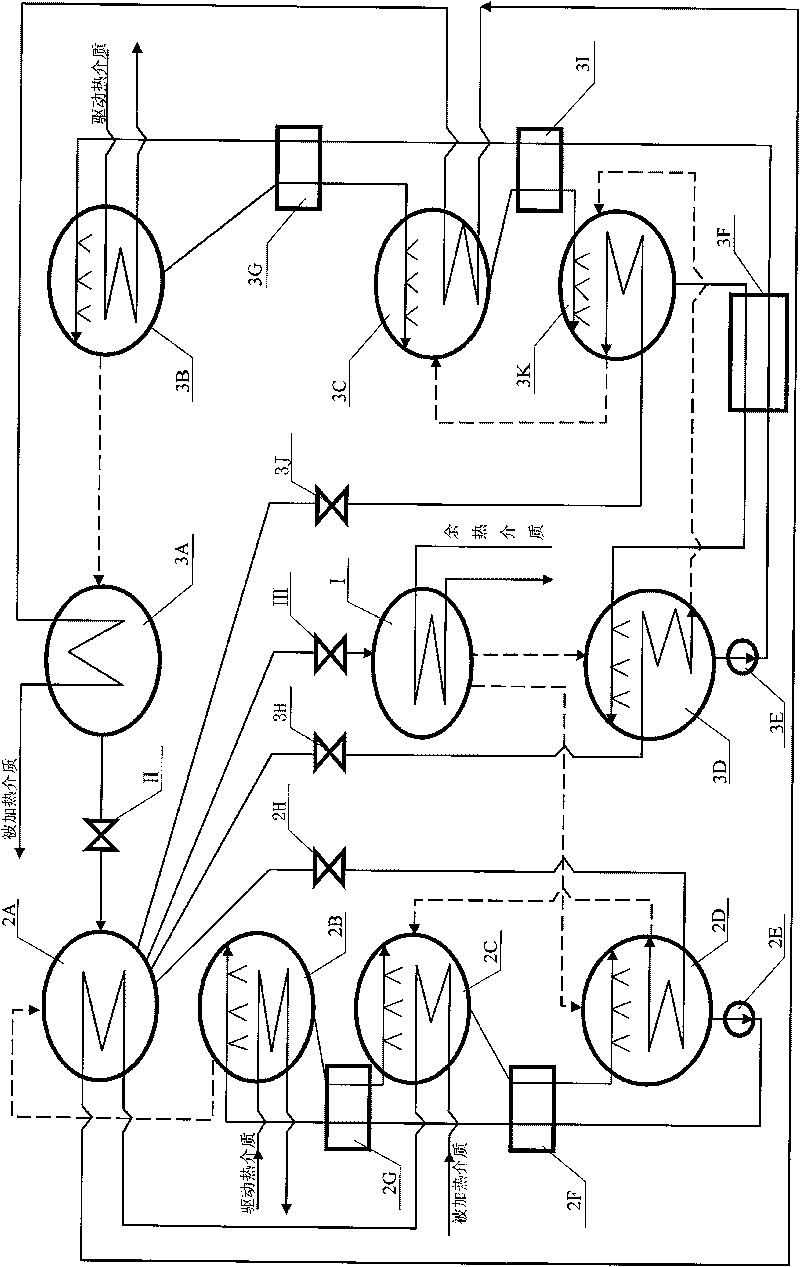

Residual heat utilization system and method for marine engine

ActiveCN109736963AHigh thermal efficiencyAvoid increasing ship loadInternal combustion piston enginesClimate change adaptationOrganic Rankine cycleWater vapor

The invention discloses a residual heat utilization system and method for a marine engine. The residual heat utilization system comprises a water vapor Rankine cycle subsystem, an organic Rankine cycle subsystem and an absorption type refrigeration cycle subsystem, wherein the water vapor Rankine cycle subsystem communicates with the marine engine, marine engine part cooling water and high temperature smoke are adopted as a working medium and a heat source of a water vapor Rankine cycle system, heat exchanger outlet smoke of the water vapor Rankine cycle system is adopted as the heat source ofan organic Rankine cycle system, the water vapor Rankine cycle system and the organic Rankine cycle system generate electricity by utilizing residual heat of the marine engine, and an absorption typerefrigeration cycle system performs refrigeration by utilizing the residual heat of the marine engine. According to the residual heat utilization system and method for the marine engine, by means ofcoupling of a variety of thermodynamic systems, gradient utilization on the residual heat of the marine engine smoke and cooling water is realized, the residual heat of the marine engine can be recycled deeply, and cold electricity co-generation can further be realized to meet marine livelihood requirements.

Owner:XI AN JIAOTONG UNIV

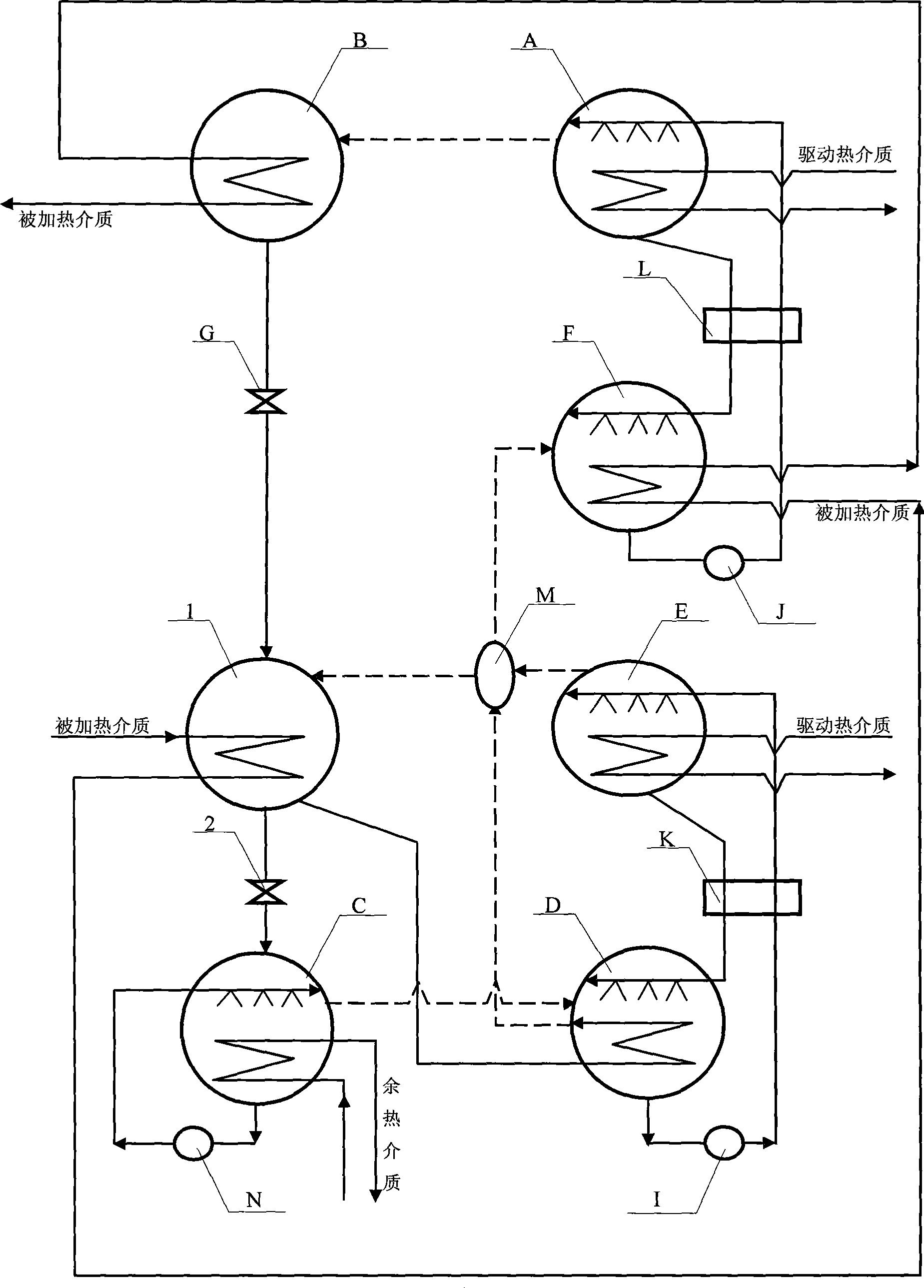

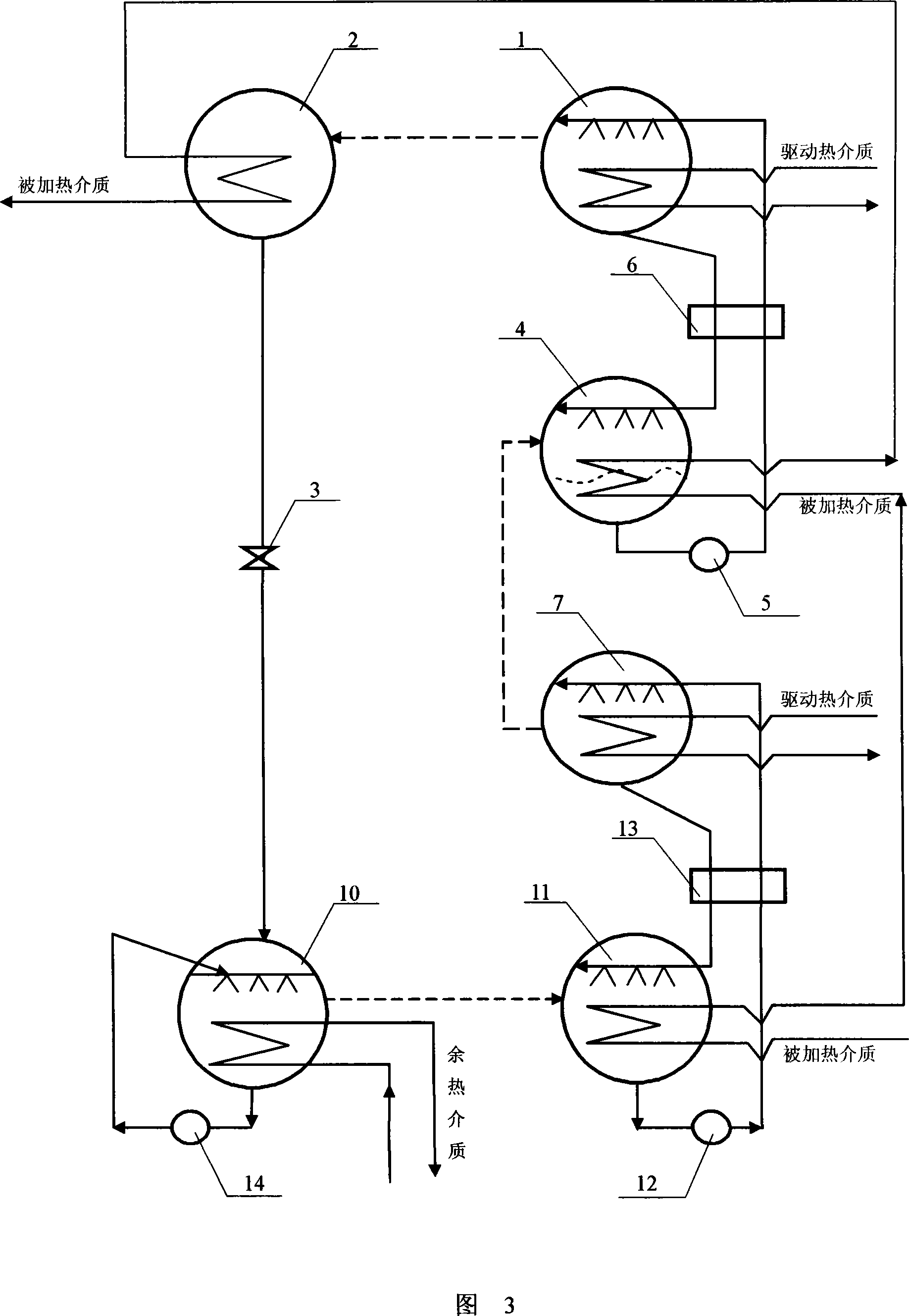

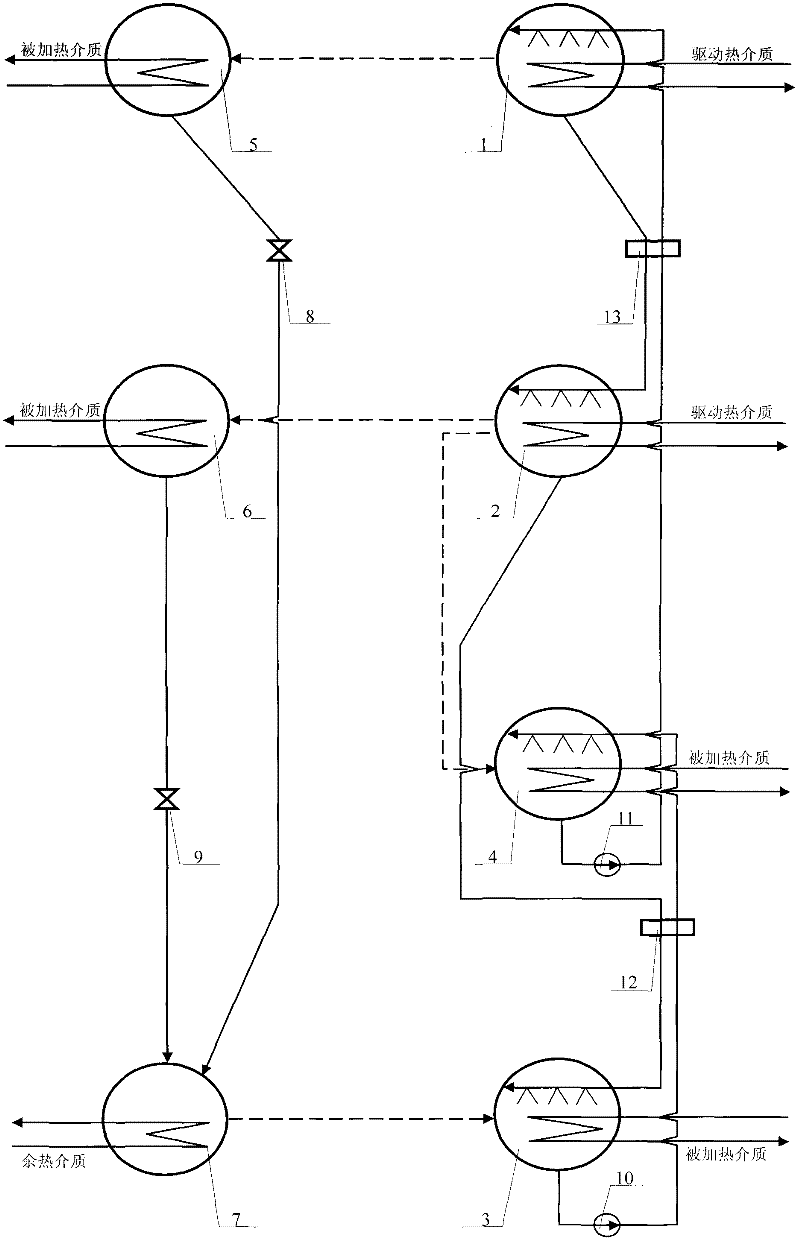

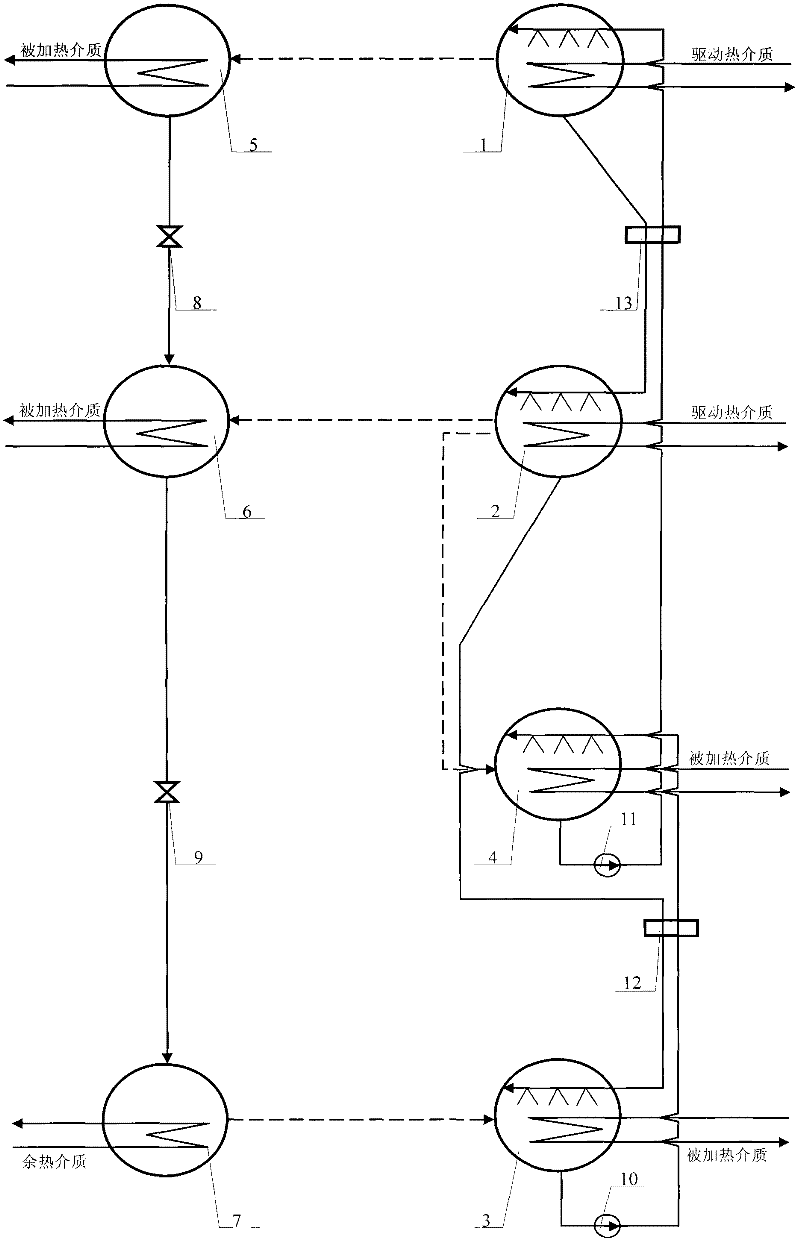

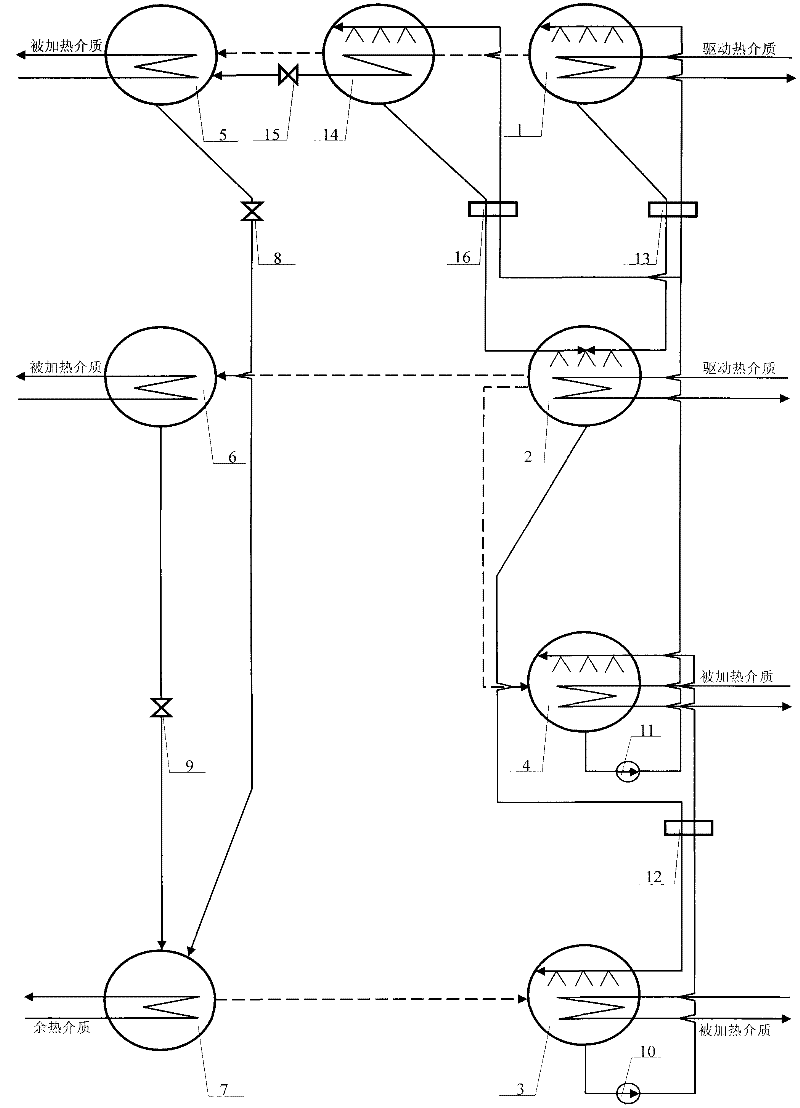

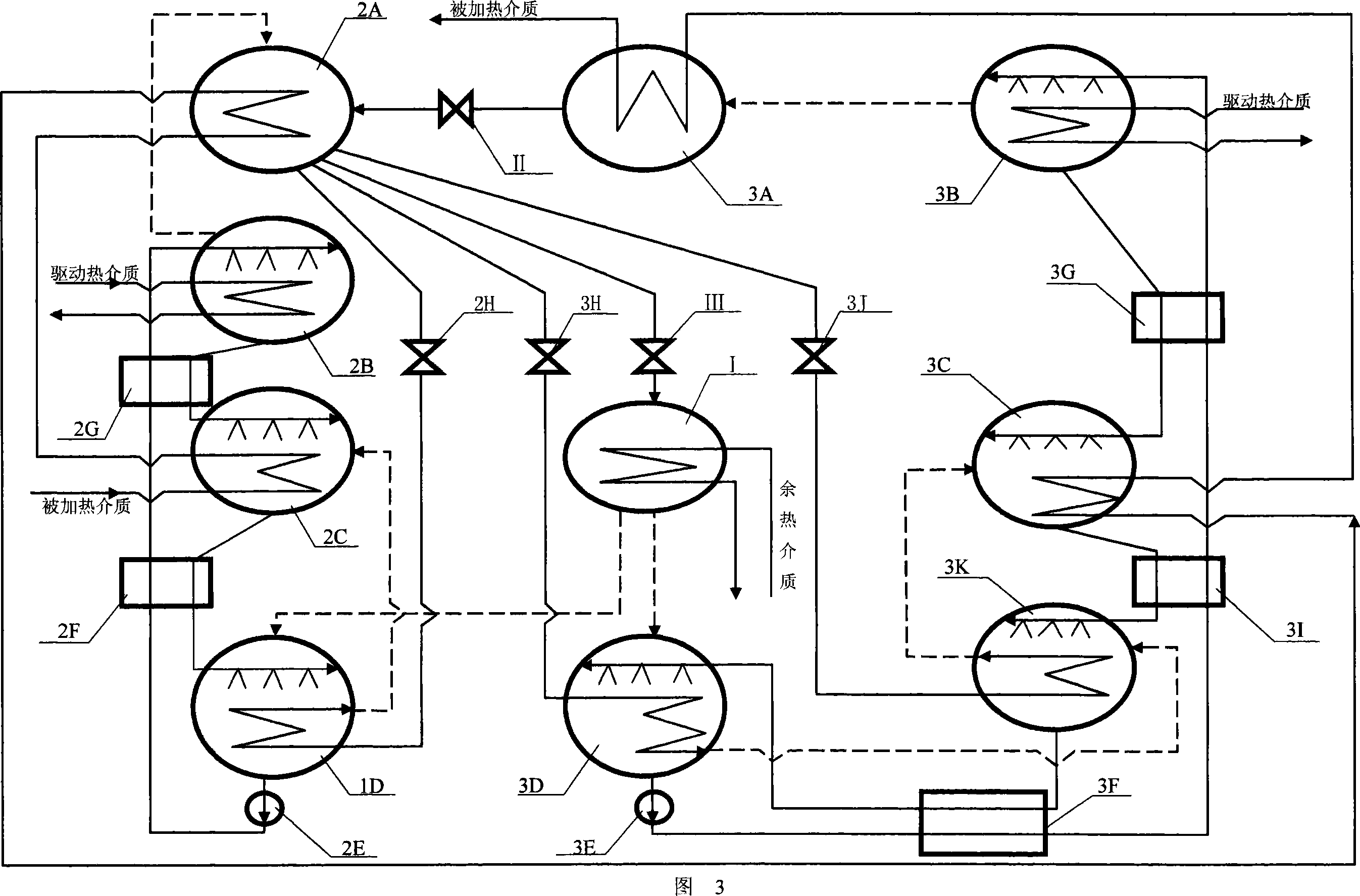

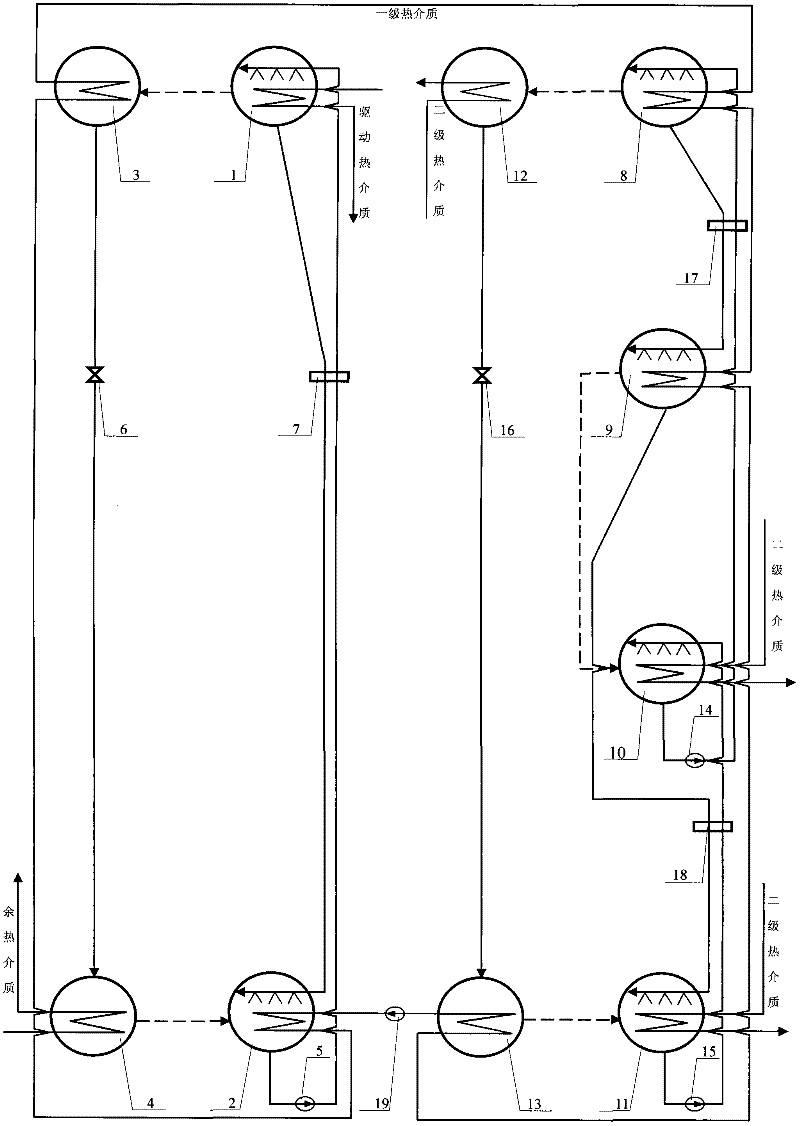

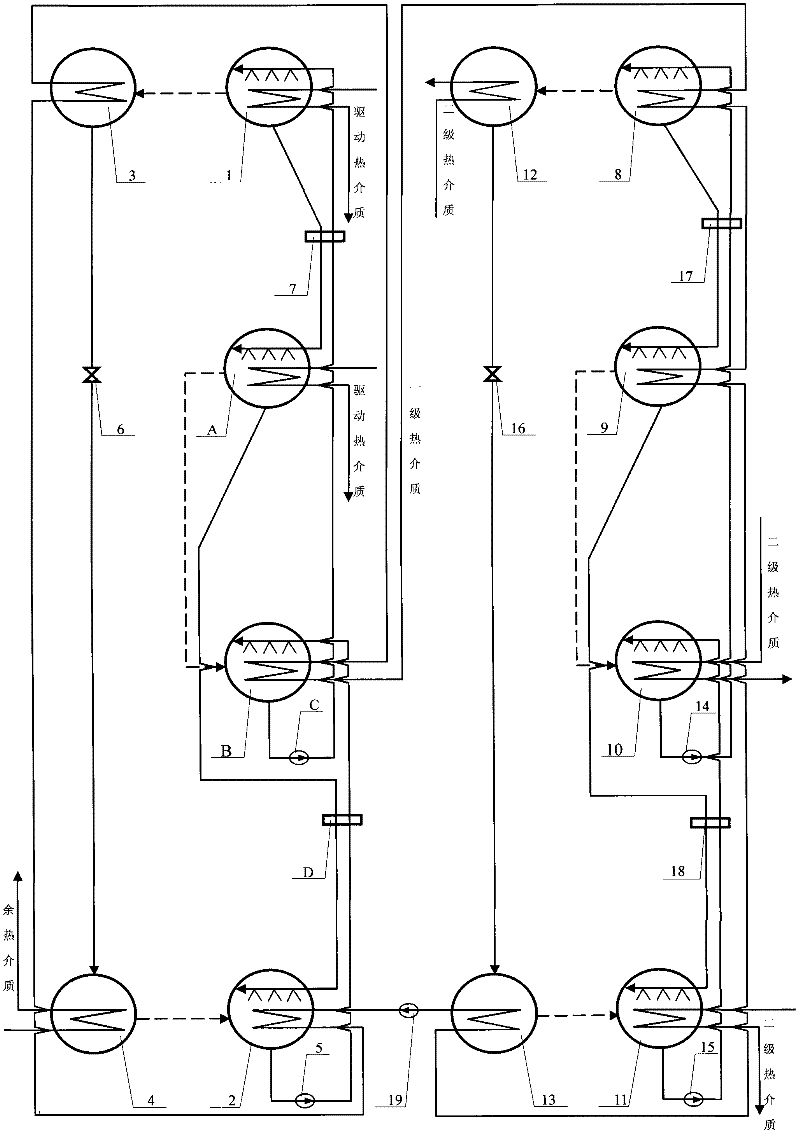

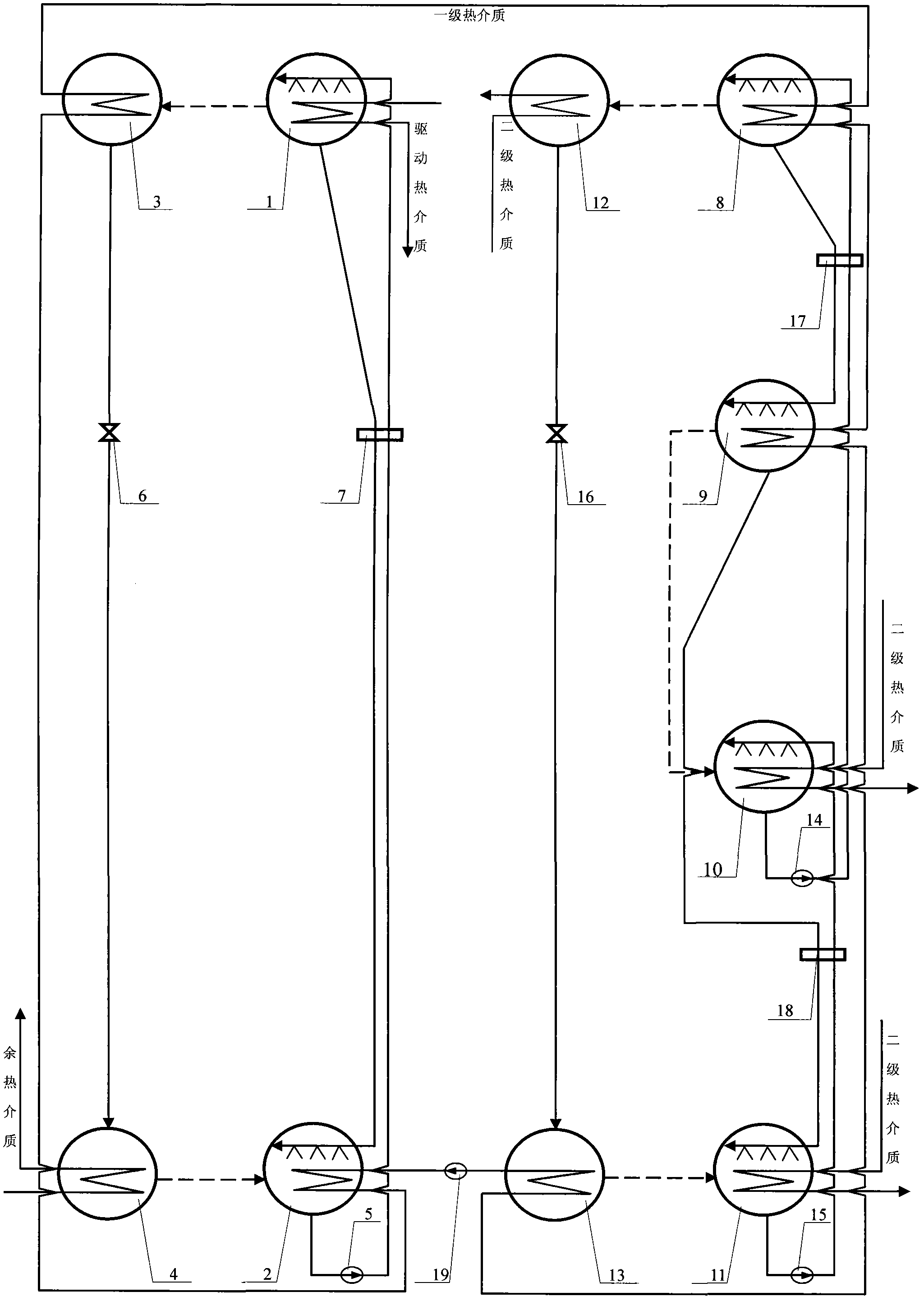

Composite absorption type heat pump formed by increasing low temperature heat supply terminal

ActiveCN101373112AMake up for the defect of low performance indexRealize deep utilizationHeat pumpsEnergy efficient heating/coolingEvaporatorEngineering

A composite absorption heat pump formed by increasing low temperature heating ends belongs to the heat pump / refrigeration technical field. The composite absorption heat pump consists of a first class generator, a condenser, an evaporator, an absorption-generator, a second class generator, an absorber, a first throttle valve / a second throttle valve or a throttle valve / a refrigerant liquid pump, a first solution pump, a second solution pump and a solution heat exchanger. A new condenser and a new throttle valve are added to a two-stage heat pump on which the absorption-generator and the first class generator provide a refrigerant vapor to the absorber; the absorption-generator and the first class generator are provided with a refrigerant vapor passage communicated with the new condenser; the new condenser is communicated with the generator through the new throttle valve; and a pipeline is communicated with medium to be heated and other necessary alternation. The first class generator, the new condenser, the new throttle valve, the generator, the absorption-generator and the first solution pump constituent a single-stage flow. The single-stage flow and a two-stage flow form a composite flow. The invention can improve the performance index of the heat pump in wide temperature range when heating at the high temperature, and the waste heat can be further utilized when refrigerating.

Owner:李华玉

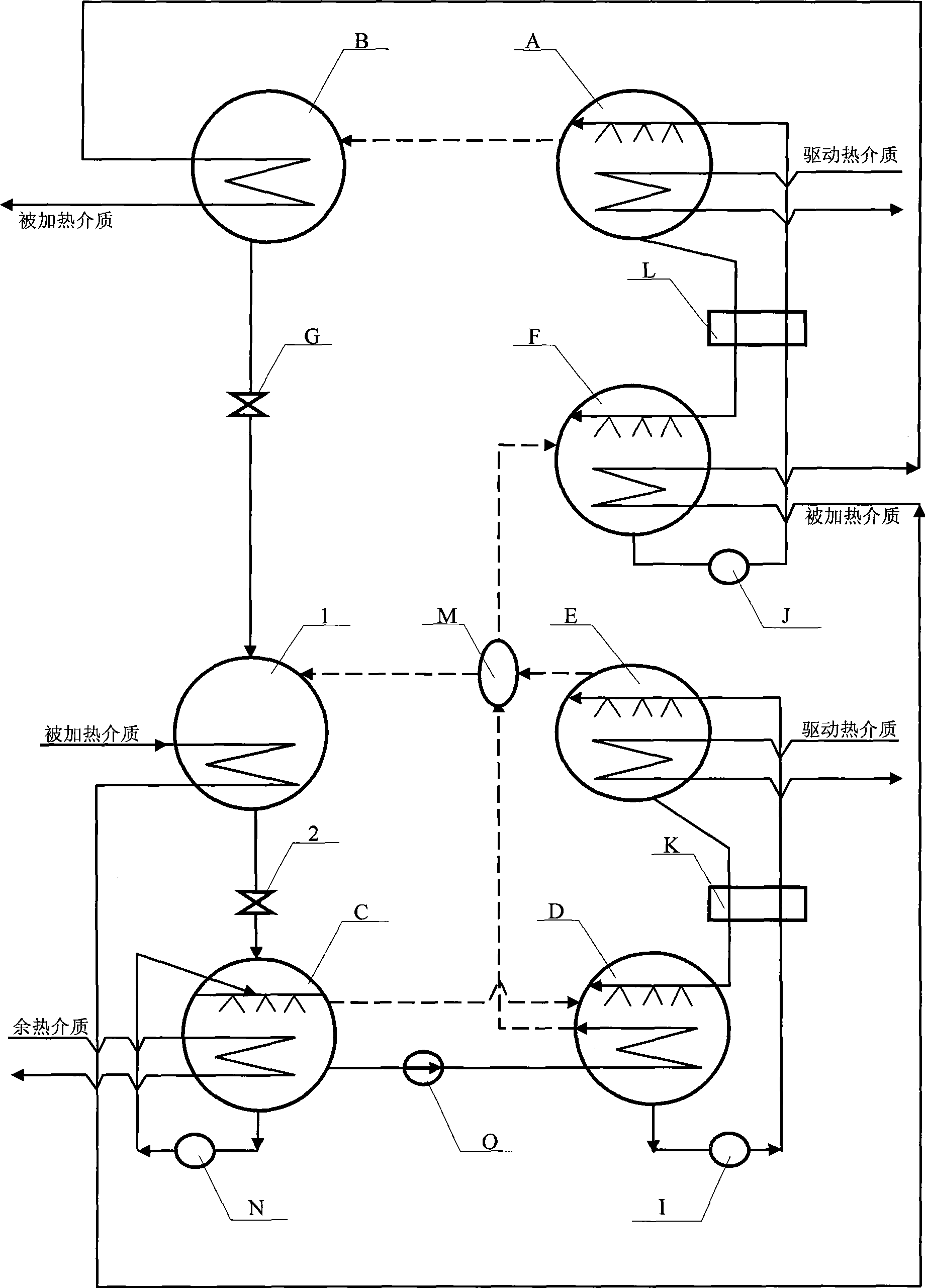

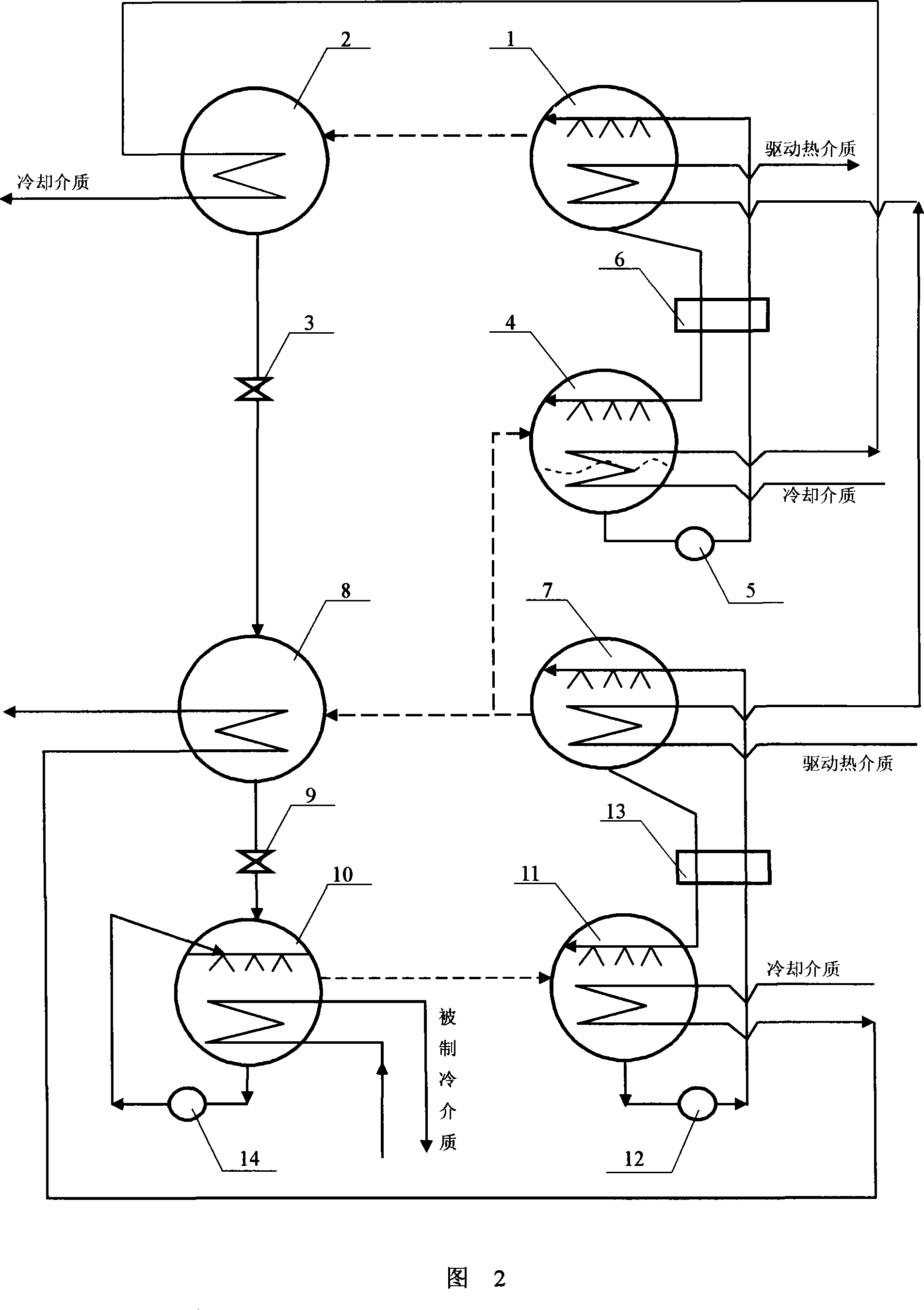

Composite absorption heat pump

ActiveCN101182962AWide heating rangeHigh heating temperatureHeat pumpsClimate change adaptationHigh energySoftware engineering

The invention provides a compound-typed first class absorption heat pump and belongs to the technical field of waste heat utilization and heat pump / refrigeration. The invention aims at the shortcomingof the single class heat pump and provides a compound integrated type machine set mainly consisting of a first class generator, a second class generator, a first class condenser, a second class condenser, a first class absorber, a second class absorber, an evaporator, a throttle, a solution pump and other basic components. A first class heat pump procedure with high performance index and a low temperature heat supply section consists of the first class generator, the first class condenser, the throttle, the evaporator, the solution pump and the first class absorber; the second class generator, the second class condenser, the throttle, the solution pump and the absorber form a second class heat pump procedure with a high temperature heat supply section and low performance index with the help of the first class procedure; wherein, the second class condenser is communicated with the first class condenser through the throttle and the first class generator is communicated with the second class absorber through a refrigerant evaporation channel; the heat pump can fully take use of the waste heat and has higher energy-saving benefit when in the high temperature heat supply in a wide temperature range; the waste heat refrigeration can make use of driven heat deeply.

Owner:李华玉

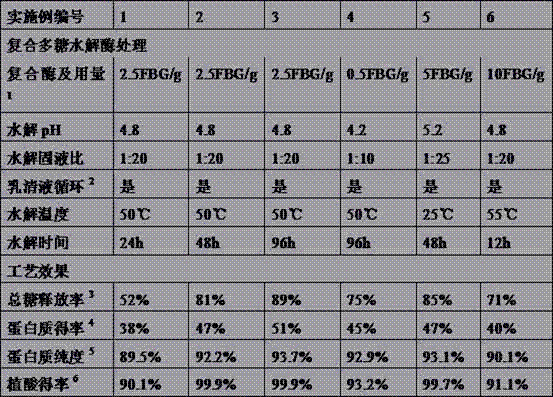

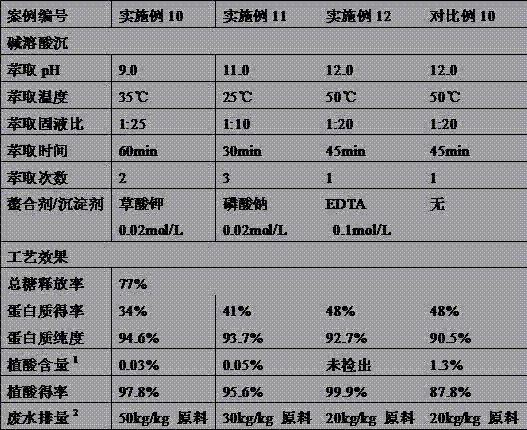

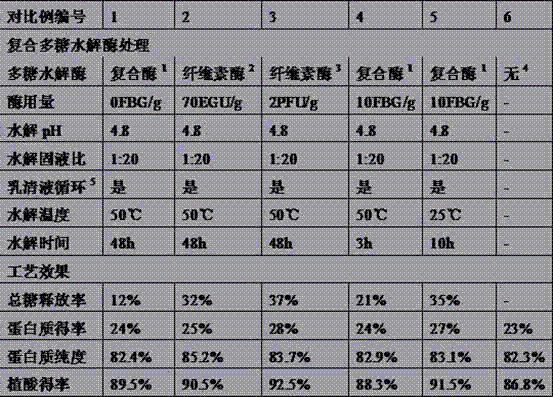

Method for extracting protein and phytic acid from rapeseed meal

InactiveCN102296099AResidue reductionEliminate residueGroup 5/15 element organic compoundsPeptide preparation methodsHydrolysatePolysaccharide Hydrolase

The method for extracting protein and phytic acid from rapeseed cake includes: using a compound of two or more polysaccharide hydrolytic enzymes to hydrolyze the rapeseed cake so that the ratio of the total sugar of the rapeseed cake released into the hydrolyzate liquid phase is greater than 50% ; Adjust the obtained hydrolyzate to pH 3-6 to extract phytic acid, and then separate solid-liquid to obtain phytic acid extract and hydrolyzed cake; use alkaline solution to extract protein in hydrolyzed cake at pH 9-12; use acid precipitation method Or membrane separation method to separate protein from alkaline extract. Improve the extraction efficiency of rapeseed protein and phytic acid, and improve the purity and quality of rapeseed protein products (reduce phytic acid residue).

Owner:刘晔

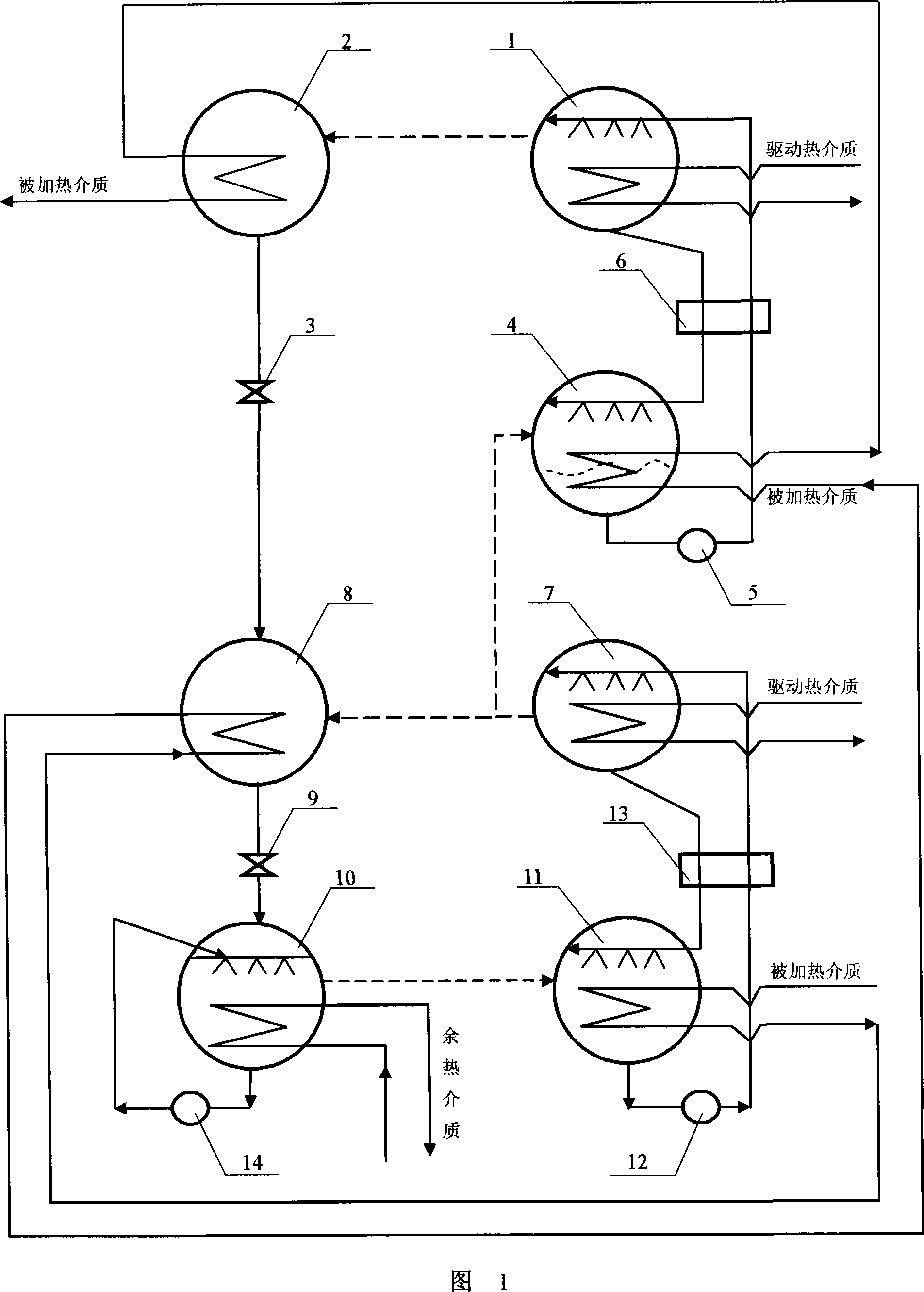

Multi-end heat supply first type absorption type heat pump

ActiveCN102384603AImprove performance indexReduce concentrationEnergy efficient heating/coolingClimate change adaptationAbsorption heat pumpProcess engineering

The invention provides a multi-end heat supply first type absorption type heat pump, which belongs to the technical field of afterheat utilization and heat pump / refrigeration and mainly consists of a first generator, a second generator, a first absorber, a second absorber, a first condenser, a second condenser, an evaporator, a first throttle valve, a second throttle valve, a first solution pump, a second solution pump, a first solution heat exchanger and a second solution heat exchanger, wherein the first absorber provides solution for the second absorber, the second absorber provides solution for the first generator, the first generator provides solution for the second generator, the second generator provides solution for the first absorber, the first generator provides coolant steam for the first condenser, the second generator provides coolant steam for the second absorber and the second condenser, the first condenser and the second condenser provide coolant liquid for the evaporator, the evaporator provides the coolant steam for the first absorber, and the multi-end heat supply first type absorption type heat pump is formed.

Owner:李华玉

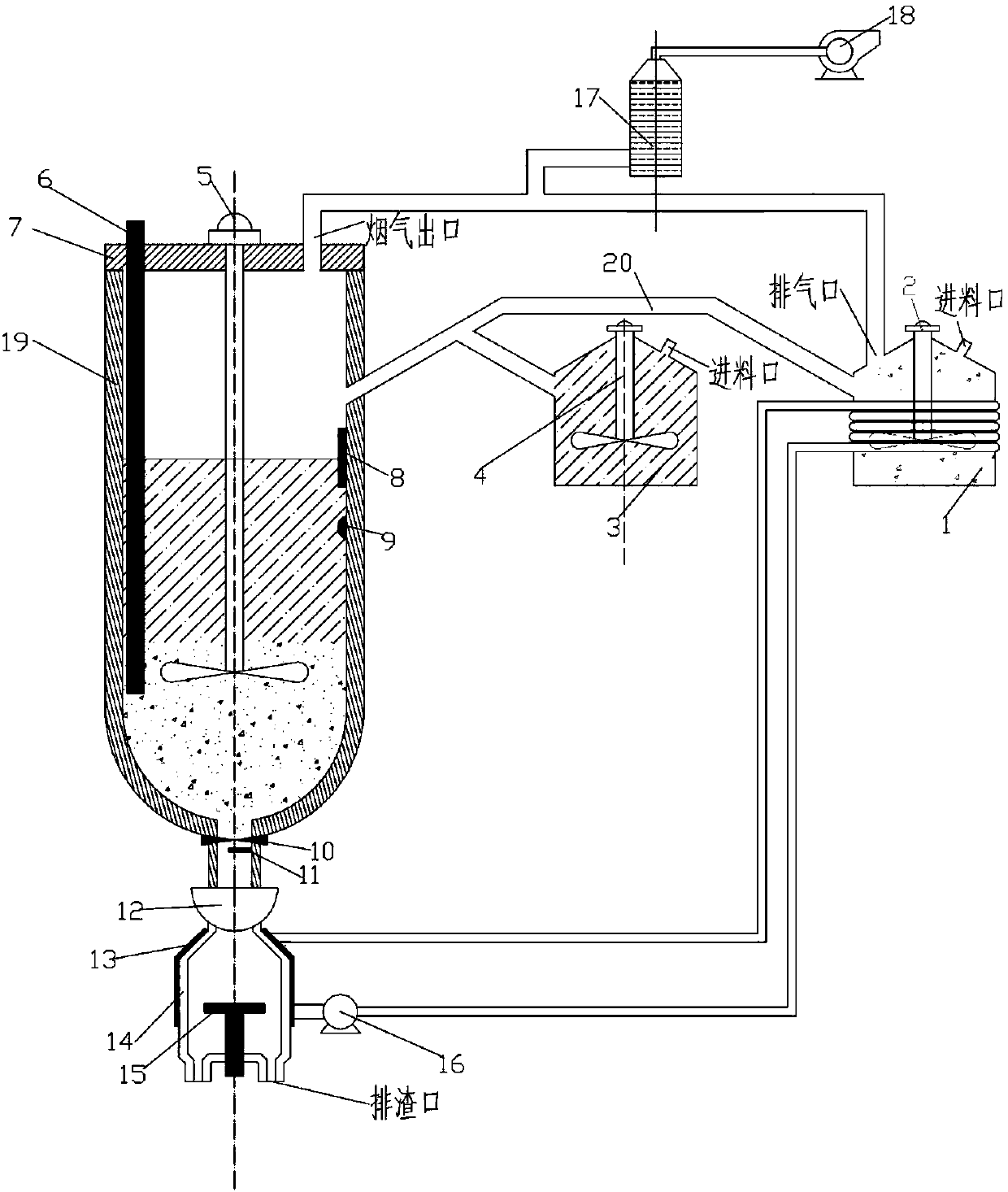

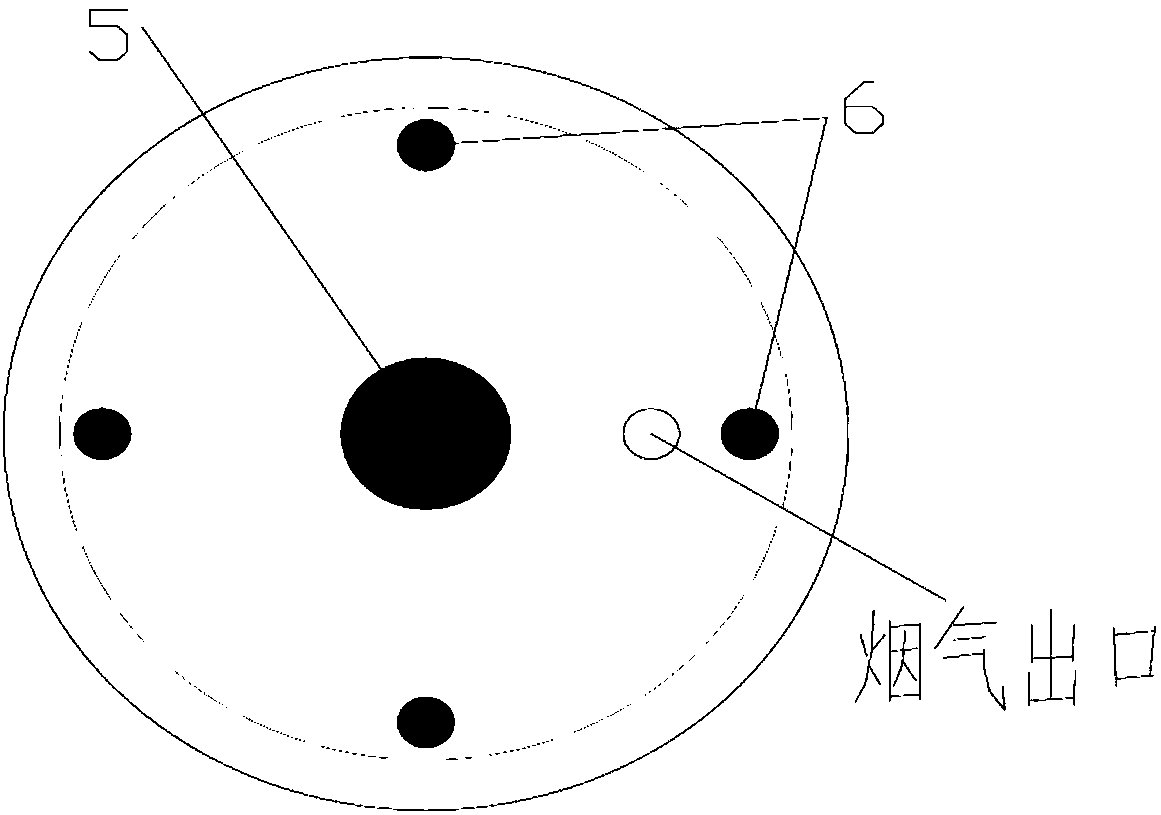

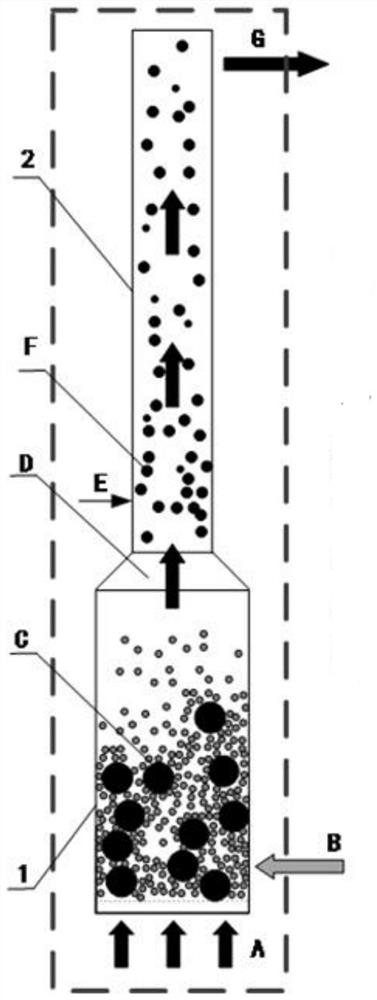

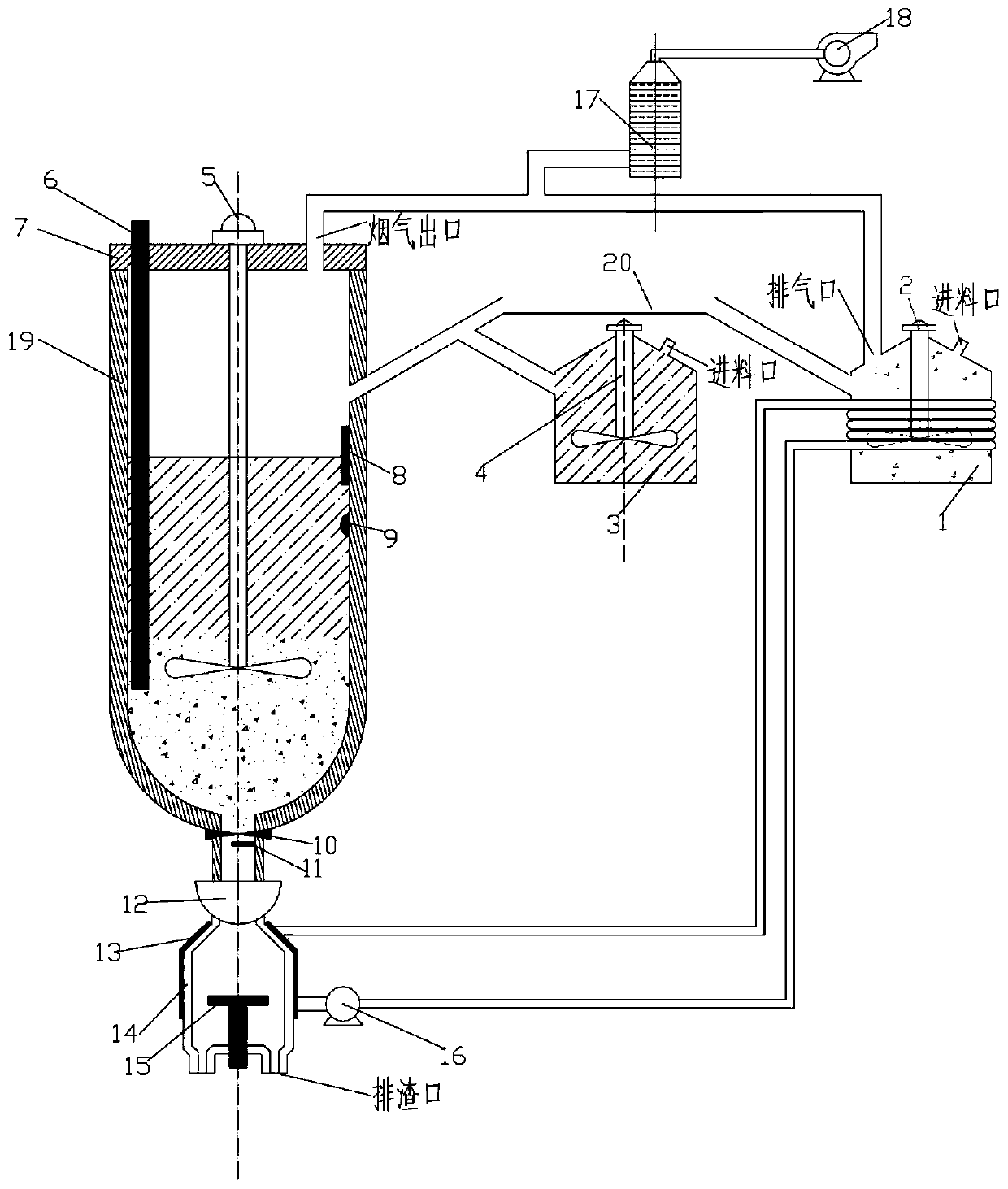

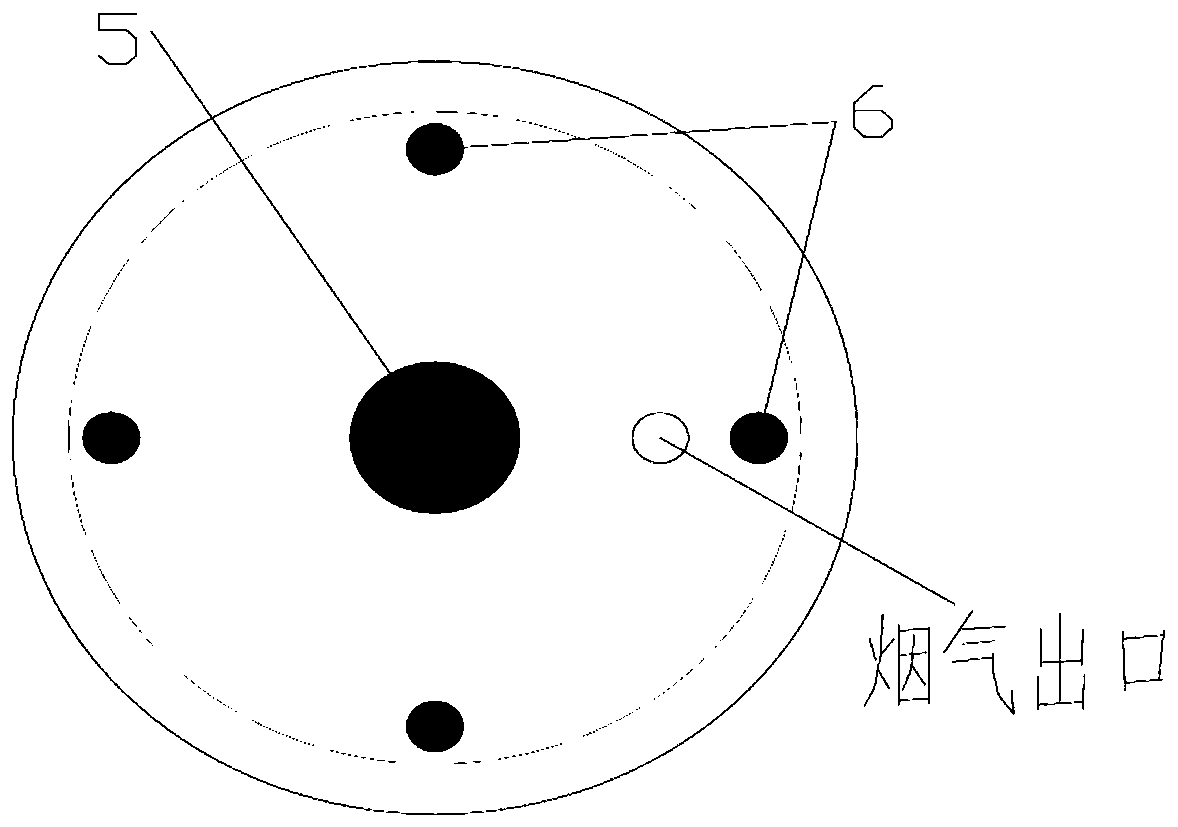

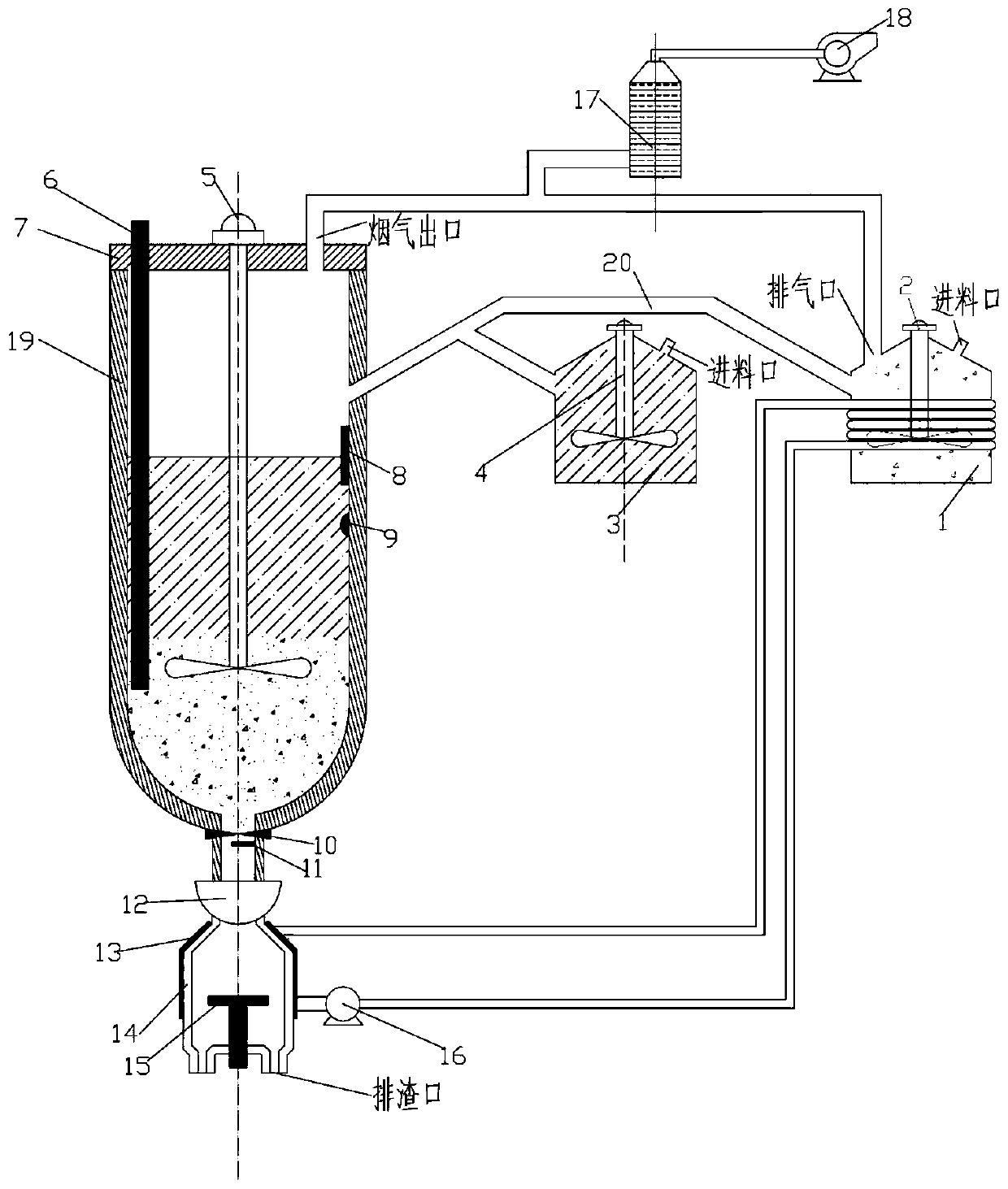

Waste incineration fly ash molten salt heat treatment system

ActiveCN107931301AEnough timePlenty of spaceTransportation and packagingSolid waste disposalResource utilizationMolten slag

The invention relates to the field of waste incineration fly ash treatment, in particular to a waste incineration fly ash molten salt heat treatment system. The waste incineration fly ash molten saltheat treatment system comprises a raw material feeding system, a fly ash heat treatment system, a discharging control system, a waste heat recycling system and a smoke gas purification system. The rawmaterial feeding system comprises a molten salt storage bin, a fly ash storage bin and a supply device; the fly ash heat treatment system comprises a reaction furnace, an electric heating bar, a stirrer and a temperature controller; the discharging control system comprises a liquid level sensor, a density sensor, a constant temperature cinder ladle, a centrifugal granulator and a catcher; the waste heat recycling system comprises a heat conduction oil heat exchanger, a hot oil circulation pump and a matching pipeline; the smoke gas purification system comprises an induced draft fan and a purification device; fly ash resource recycling and detoxification treatment is achieved synchronous with fly ash molten salt heat treatment, and through tail gas purification, intelligent slag discharging and molten slag waste heat recycling, energy saving emission reduction and product deep resource utilization in the fly ash heat treatment process can be promoted.

Owner:HUAZHONG UNIV OF SCI & TECH

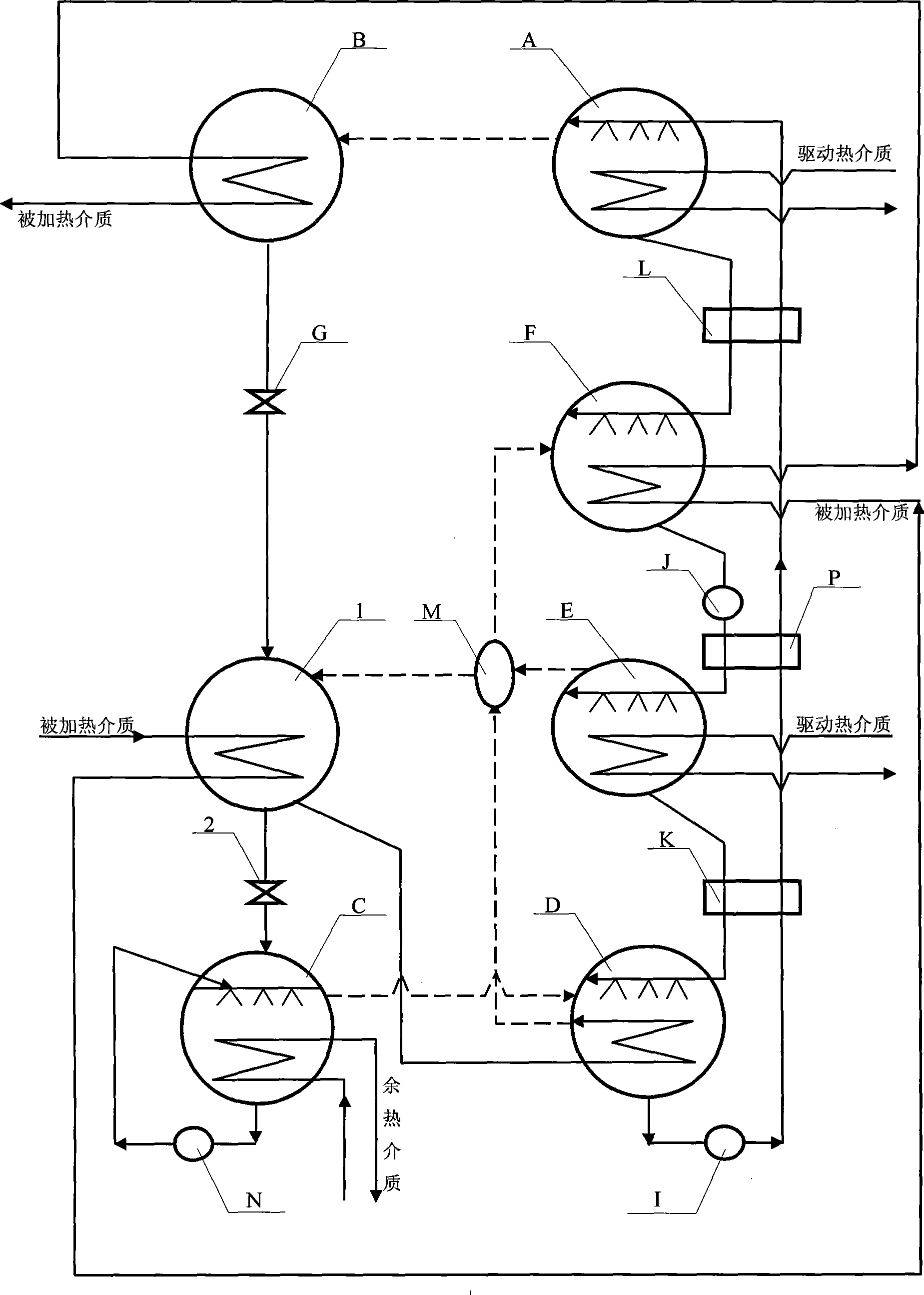

Different grade composite first kind absorption heat pump

ActiveCN101182961AMeet needsImprove performance indexHeat pumpsEnergy efficient heating/coolingComing outEvaporation

The invention provides a different-level compound first class absorption-typed heat pump and belongs to the technical field of waste heat utilization and heat pump / refrigeration. The invention aims atthe shortcoming of a single class heat pump and provides an integrated machine set consisting of a generator, a condenser, an absorber, an evaporator, an absorption-evaporation device, a throttle valve, a solution pump and other basic components; the invention is divided into three types respectively with a common evaporator, a common condenser or no common component; the processes of the heat pump in different levels are compounded through the evaporator or the condenser and / or waste heat medium channel simply while accompanied by other components; when sharing the evaporator, each condenser is interconnected through the throttle valve or is separated from each other or is separated partly; when under other conditions, waste heat medium enters into and comes out of each evaporator in sequence; refrigerant medium from the condenser enters into the evaporator and the absorption-evaporation device through the throttle valve and is absorbed by solution at each associated connection; diluted solution releases refrigerant into the condenser with the action of driven heat. The heat pump can take use of waste heat and refrigeration with waste heat has high benefit.

Owner:李华玉

Method for synergistically realizing efficient removal of PM2.5/SO3 in high-moisture flue gas and zero water consumption in wet desulphurization

InactiveCN106669345APrevent evaporationReduce the temperatureCombination devicesGas treatmentWater vaporFine particulate

The invention provides a method for synergistically realizing efficient removal of PM2.5 / SO3 in high-moisture flue gas and zero water consumption in wet desulphurization. The method comprises the following steps: making the high-moisture flue gas pass through a low-temperature heat exchanger before entering an electric precipitator, so that the smoke temperature drops below an acid dew point, gaseous SO3 in the flue gas is condensed and adsorbed onto the surface of fine particulate matters, the PM2.5 removal of the electric precipitator is enhanced, and synergistic removal of SO3 is realized; after the flue gas leaves the electric precipitator, further cooling through a low-low-temperature heat exchanger to obtain high-relative-humidity flue gas, then reaching oversaturation in a desulfurization tower within a low-temperature desulfurization fluid contact process, and nucleating and condensing the oversaturated water vapor on the acid mist surface of the PM2.5 and the SO3, so that the particle size increases, and the removal of the acid mist of the PM2.5 and the SO3 in the desulfurization process is facilitated. At the same time, an oversaturated water vapor environment is established in the tower, so that a part of moisture is condensed from the flue gas to the desulfurization fluid, and zero water consumption in the wet desulphurization is realized synergistically. The method has the characteristics of high efficiency, energy saving, low investment and treatment cost, and the like.

Owner:SOUTHEAST UNIV

Method for two-stage preparation of methane gas from solid waste

ActiveCN113477190AImprove quality and increase productionAchieve reductionGaseous fuelsWaste based fuelPtru catalystMethanation

The invention discloses a method for two-stage preparation of methane gas from solid waste. The method comprises the following steps: step 10) in a first-stage methanation area, introducing water vapor from the bottom of the area, introducing solid waste and a modified calcium-based ore catalyst from a side edge, and under the action of the water vapor, mixing the solid waste and the modified calcium-based ore catalyst and allowing the mixture of the solid waste and the catalyst to ascend and undergo direct methanation reaction with water vapor to obtain crude methane gas; and step 20) discharging the crude methane gas from the top of the first-stage methanation area, feeding the crude methane gas into a second-stage methanation area, uniformly feeding hydrogen into the second-stage methanation area, pre-regulating the hydrogen-carbon ratio of the crude methane gas, carrying out catalytic methanation reaction on methane gas by using a catalytic methanation catalyst, and preparing high-quality methane gas via the catalytic methanation catalyst under the fluidization action of the hydrogen and the crude methane gas. The method can achieve the effects of high fuel utilization rate, high methane quality and low catalysis cost.

Owner:SOUTHEAST UNIV

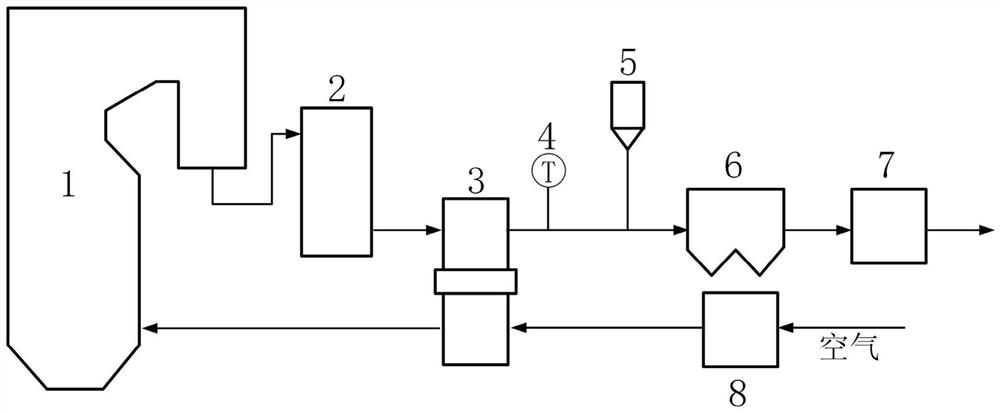

Gas boiler system

InactiveCN104089283AEmission reductionLow costCombustion technology mitigationCombustion using catalytic materialNitrogen oxidesProcess engineering

The invention discloses a gas boiler system, which comprises a furnace body, a catalytic reactor, a smoke exhaust pipeline, a smoke residual heat utilizing device and a smoke re-cooling device, wherein a smoke exhaust opening is formed in the furnace body; the catalytic reactor is arranged in the furnace body and is used for promoting NO in the smoke to be oxidized to NO2 before the smoke is exhausted from the smoke exhaust opening; the smoke exhaust pipeline is arranged outside the furnace body, is connected with the smoke exhaust opening of the furnace body and is used for receiving exhausted smoke and exhausting the smoke to the atmosphere; the smoke residual heat utilizing device is arranged in the smoke exhaust pipeline and is used for receiving the smoke exhausted from the furnace body, so that the smoke exchanges heat with a first medium to heat the first medium and cool the smoke to separate out condensate water; the smoke re-cooling device is arranged at the downstream of the smoke residual heat utilizing device and is used for further cooling the smoke exhausted from the smoke residual heat utilizing device; while working, the condensate water is used for absorbing NO2 in the smoke. According to the gas boiler system, at the time that the emission of nitrogen oxide is greatly reduced, deep recycling of residual heat of smoke condensing is realized.

Owner:北京华通兴远供热节能技术有限公司 +1

A system and method for utilizing waste heat of a ship engine

ActiveCN109736963BHigh thermal efficiencyAvoid increasing ship loadInternal combustion piston enginesClimate change adaptationOrganic Rankine cycleWater vapor

Owner:XI AN JIAOTONG UNIV

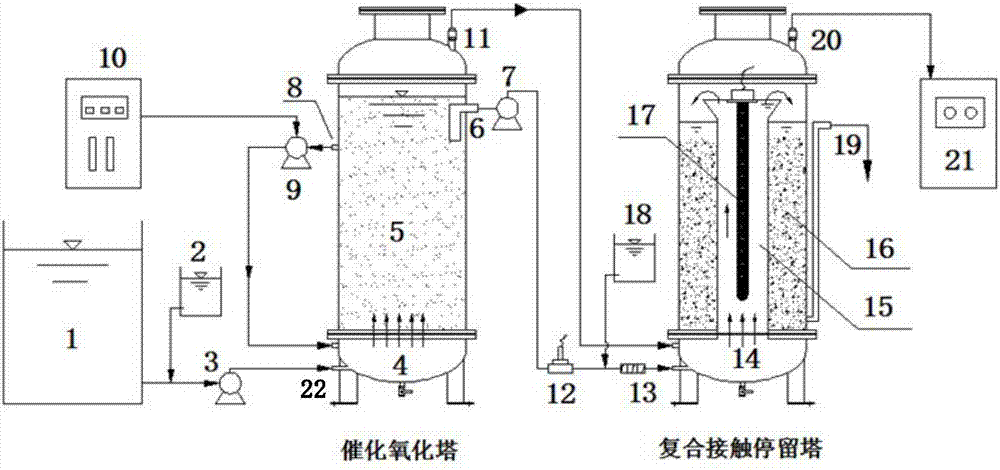

Device and method for treating pharmaceutical tail water

InactiveCN107010767AImprove mass transfer efficiency and utilization efficiencyAchieve rapid degradationWater treatment parameter controlWater/sewage treatment by irradiationPollutantChemistry

The invention provides a device and method for treating pharmaceutical tail water. The device for treating the pharmaceutical tail water comprises a catalytic oxidation tower and a composite contact stop tower, wherein a first water distribution area is arranged at the lower part of the catalytic oxidation tower; a catalytic reaction area is arranged at the upper part of the first water distribution area; a first catalyst is fed to the catalytic reaction area; a second water distribution area is arranged at the lower part of the composite contact stop tower; a contact stop area is arranged at the upper part of the second water distribution area; the contact stop area comprises a UV photocatalytic stop area communicating with the top of the second water distribution area and a fixed bed contact stop area separated from the second water distribution area. Different types of catalytic oxidation reactions are fully utilized and grading oxidation treatment is carried out on refractory organic compounds in the pharmaceutical tail water, so that removal of pollutants and efficient utilization of ozone are achieved to the maximum extent.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

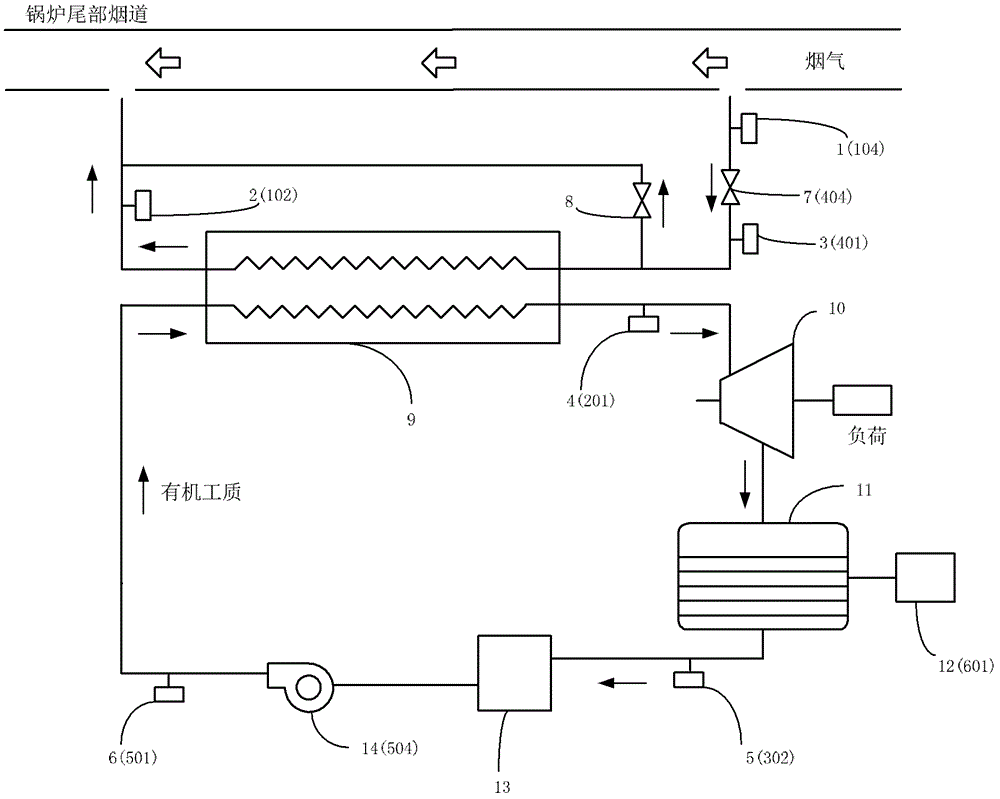

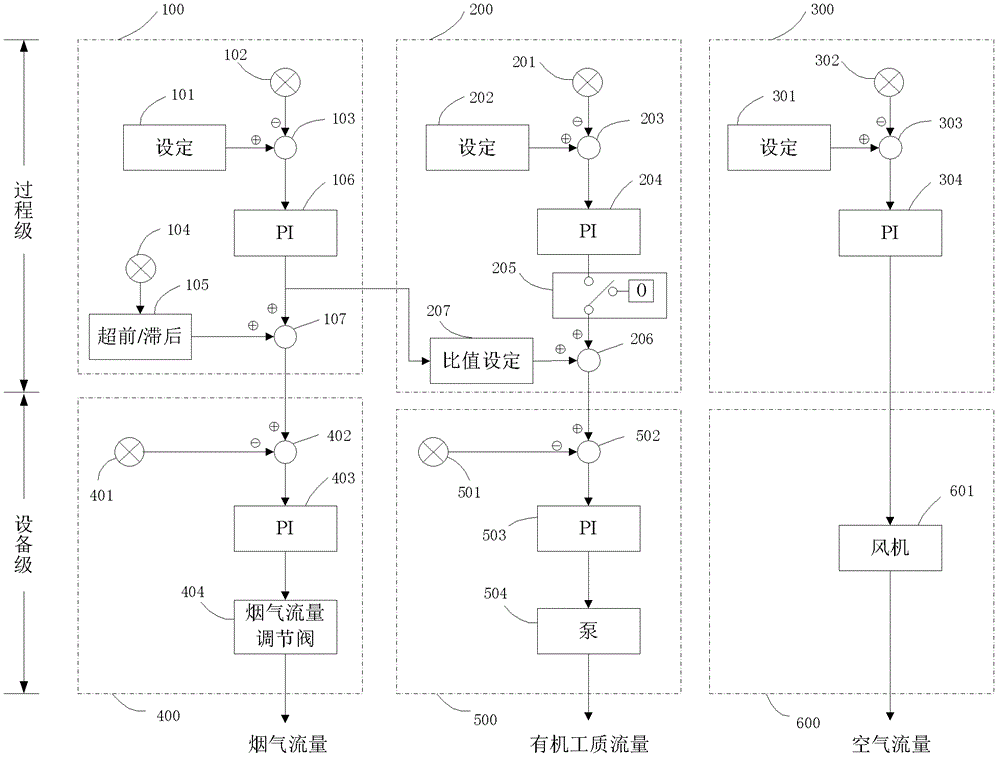

Boiler flue gas waste-heat utilization system based on organic Rankine cycle

InactiveCN102644488BRealize deep utilizationSimple structureIncreasing energy efficiencySteam engine plantsOrganic Rankine cycleFlue gas

The invention discloses a boiler flue gas waste-heat utilization system based on organic Rankine cycle, which belongs to the technical field of the process control. The boiler flue gas waste-heat utilization system is composed of a flue gas flow control subsystem, an organic working-medium flow control subsystem and an air flow control subsystem, wherein the flue gas flow control subsystem adopts a cascading and feed-forward control structure, the temperature of the flue gas at an outlet of an evaporator is adjusted by controlling the flue gas flow, and the influence of the temperature disturbance on a flue gas inlet is eliminated by a feed-forward step; the organic working-medium flow control subsystem adopts a change ratio value control structure and the working-medium flow is adjusted to proportionally change with the flue gas flow during the operation process; and the air flow control subsystem adopts a feedback control structure and the air flow in a condenser is changed to adjust the temperature of the working medium at an outlet of the condenser to a reset value. The structure of the boiler flue gas waste-heat utilization system is simple, the construction is convenient, and the stability, economical efficiency and safety of the waste-heat utilization process are ensured.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

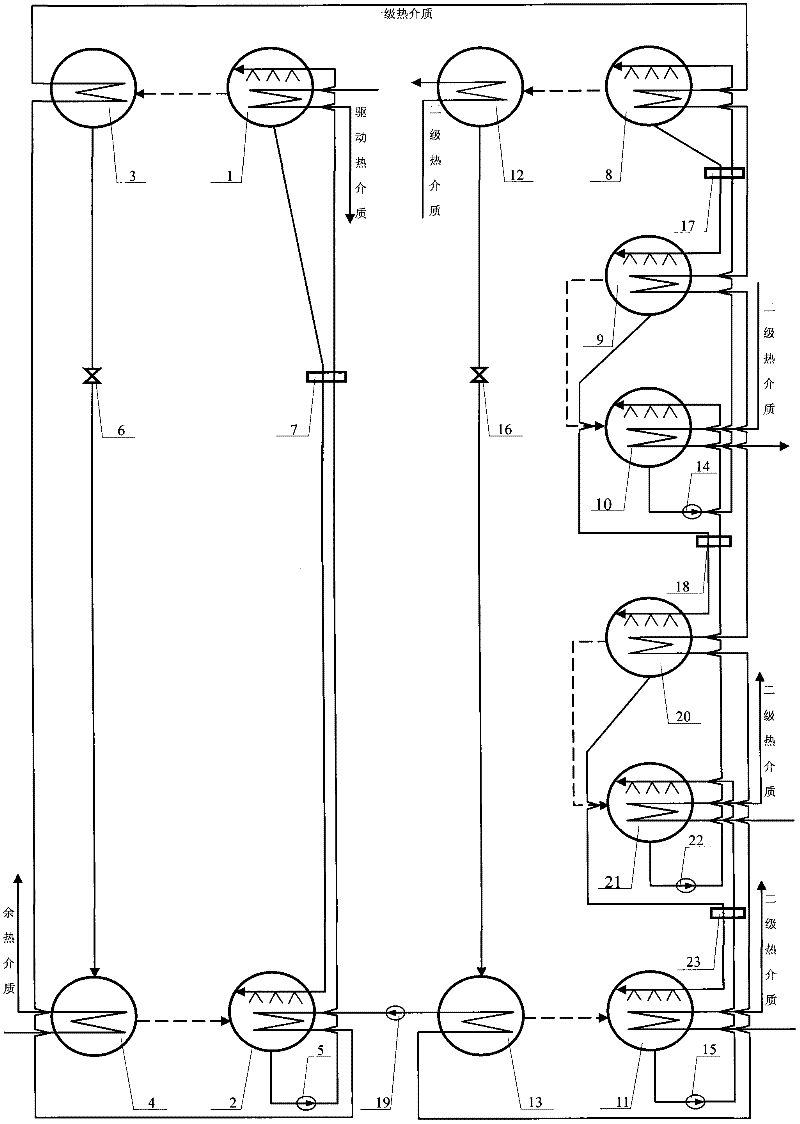

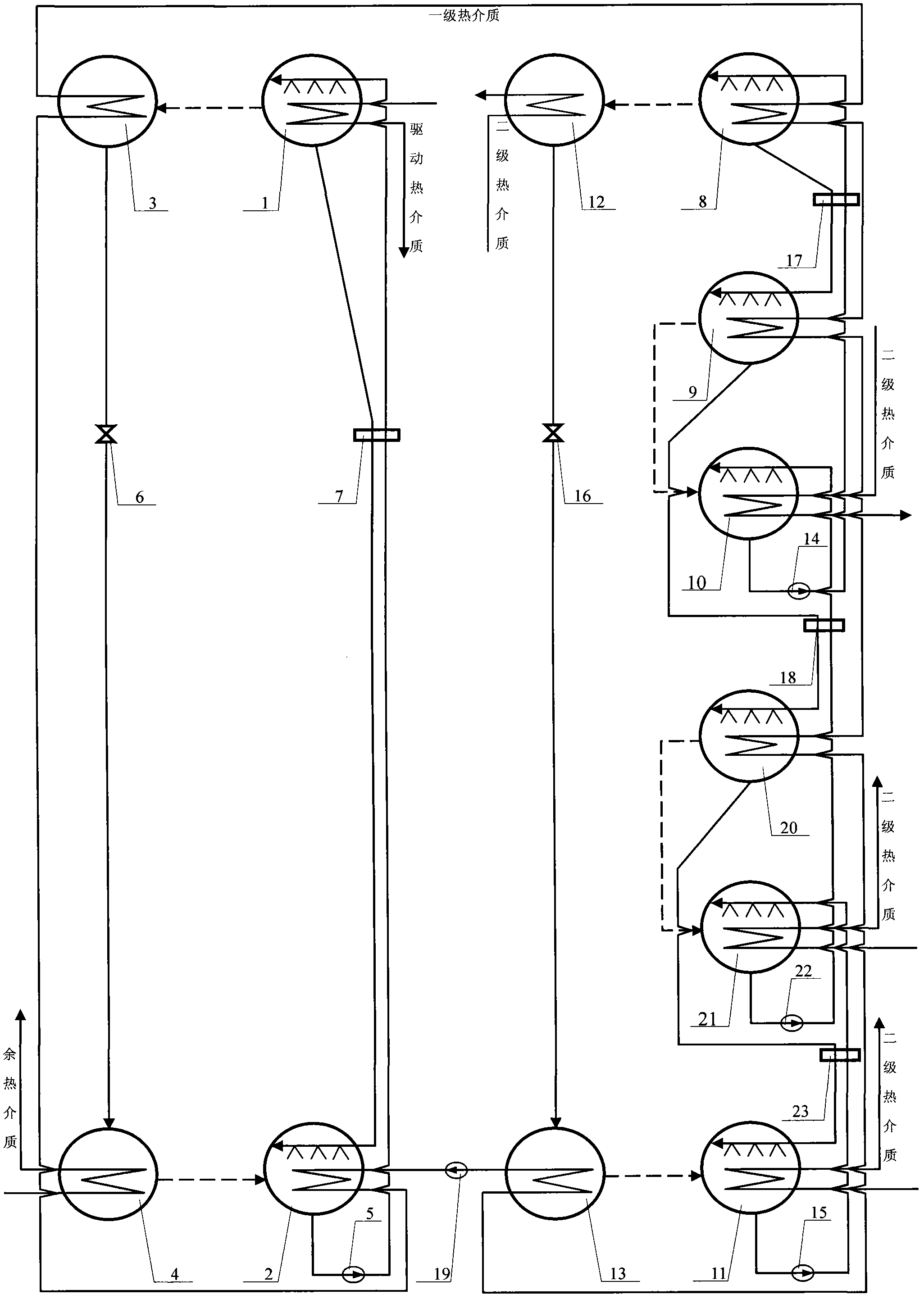

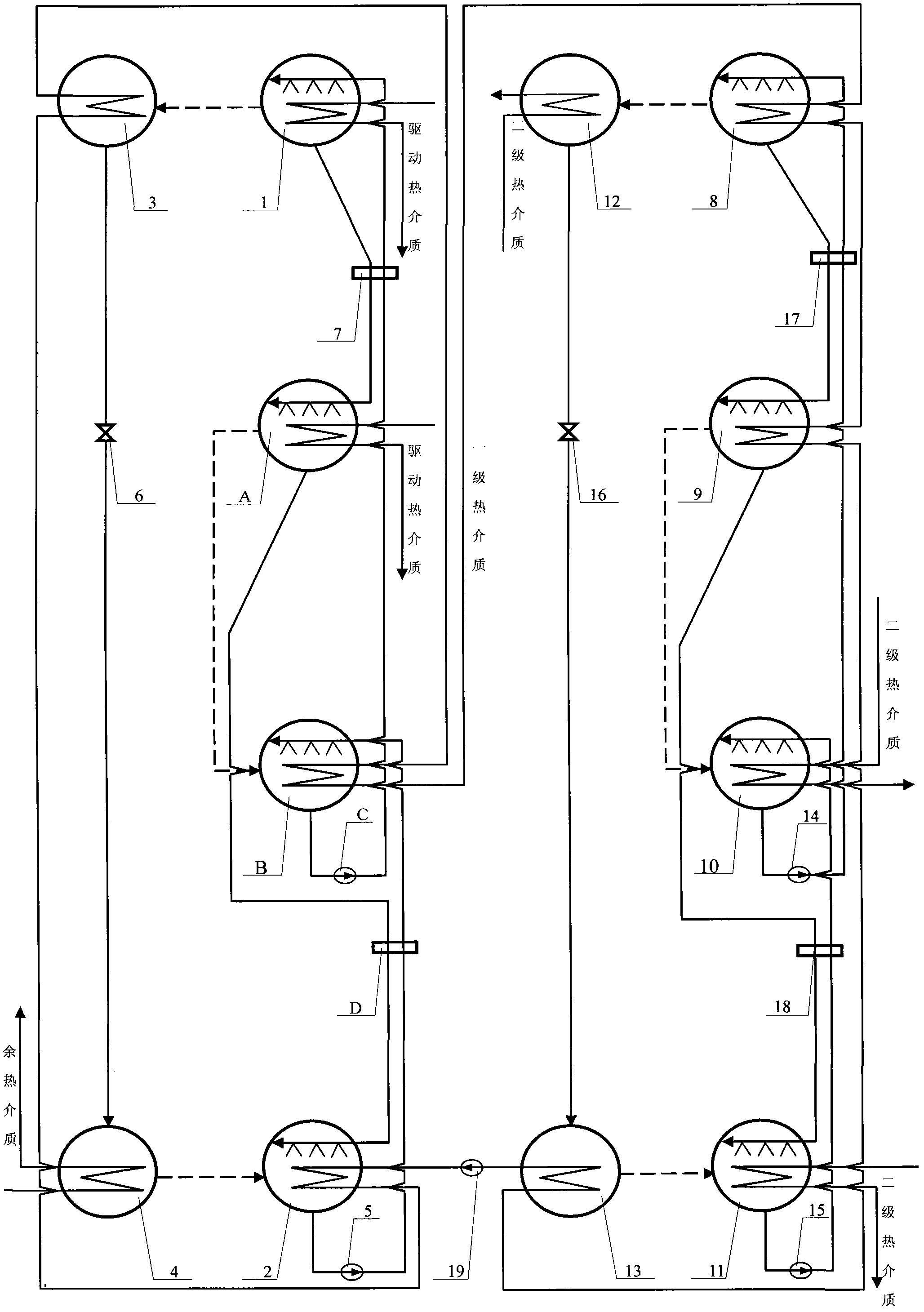

Absorption type grading heat supply system

ActiveCN102410575AAdjustable heating loadRealize deep utilizationLighting and heating apparatusEnergy efficient heating/coolingProcess engineeringRefrigeration

The invention provides an absorption type grading heat supply system, belonging to the technical field of waste heat utilization and heat pump / refrigeration. A first generator, a first absorber, a first condenser, a first evaporator, a first solution pump, a first throttle valve, a first solution heat exchanger, a newly-added generator, a newly-added absorber, a newly-added solution pump and a newly-added solution heat exchanger form a primary heat medium heating process; a second generator, a third generator, a second absorber, a third absorber, a second condenser, a second evaporator, a second solution pump, a third solution pump, a second throttling valve, a second solution heat exchanger and a third solution heat exchanger form a secondary heat medium heating process; and a primary heat medium flows through the secondary heat medium heating process and provides a drive heat load and a low-temperature heat load, and a circulating pump realizes primary heat medium circulating flowing. Corresponding parts are additionally provided, thus a series of absorption type grading heat supply systems are obtained.

Owner:李华玉

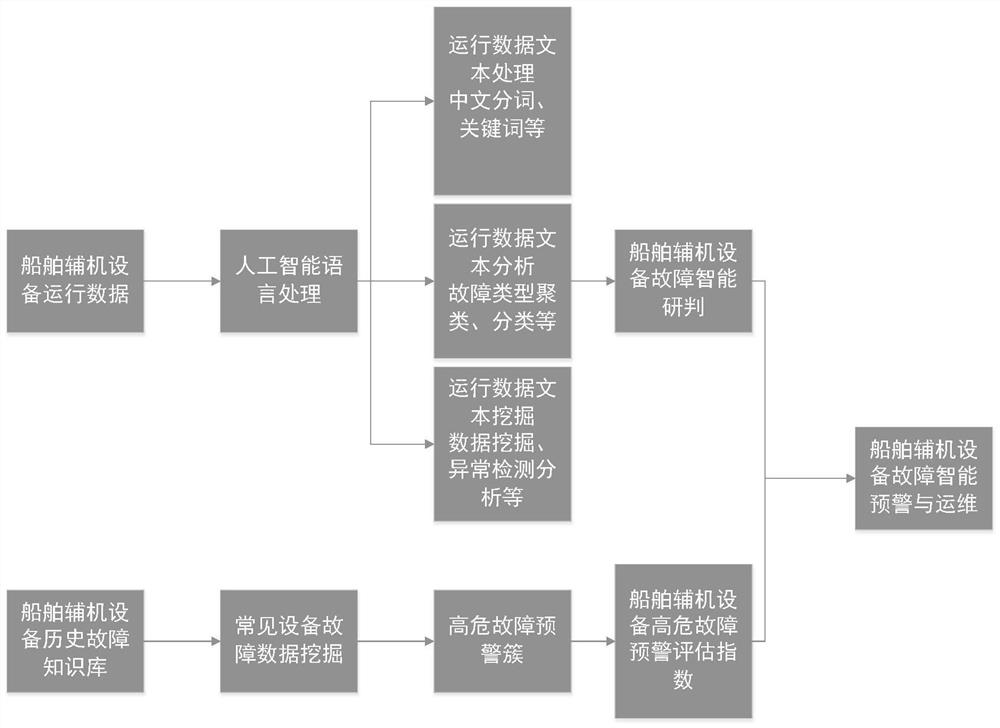

Marine auxiliary equipment fault intelligent early warning design method based on artificial intelligence

PendingCN113313272AReduce maintenance costsImprove the level of intelligenceSemantic analysisCharacter and pattern recognitionAlgorithmMachine

The invention discloses a marine auxiliary engine equipment fault intelligent early warning design method based on artificial intelligence in the technical field of fault intelligent early warning. The method comprises the following steps: 1, naming an entity extraction rule and a semantic sentiment analysis algorithm; 2, calling data of samples in the historical knowledge base for study and judgment, and performing secondary processing on operation data of auxiliary equipment; 3, obtaining key operation information of the auxiliary machine equipment; and 4, extracting actual operation data and key operation indexes of the marine auxiliary equipment, carrying out data classification, and selecting classification analysis in a manual supervision mode to realize intelligent monitoring and state self-analysis of the ship auxiliary equipment. Deep utilization of historical operation data of the ship auxiliary equipment is realized, heterogeneous data intercommunication and information fusion are fully realized, the intelligent level of operation and maintenance can be improved in actual engineering application, and the maintenance cost of ship auxiliary equipment can be reduced.

Owner:江苏杰瑞信息科技有限公司

Jet typed sectional generating absorbing typed circulation

InactiveCN103542600ARealize deep utilizationIncrease concentrationMechanical apparatusClimate change adaptationThermal energyEngineering

A jet typed sectional generating absorbing typed circulation comprises a high temperature absorber, a condenser, a first throttle valve, an evaporimeter, an absorber, a solution pump, a first solution heat exchanger, a second solution heat exchanger, a third solution heat exchanger, an additional generator, an ejector, a generator or a high pressure generator, a low pressure generator and a second throttle valve. A jet typed heat pump is dynamically integrated with an absorption heat pump, and the concentration of solution at an exit of the high temperature absorber is increased after at least two generating processes. The jet typed sectional generating absorbing typed circulation has the advantages that when driving heat source is latent heat, steam from different grades can be utilized, when driving heat source is sensible heat, deep utilization of driving heat source can be realized, and meanwhile, higher heating temperature and more efficient heat energy use ratio can be acquired, efficient utilization of high-quality driving steam can be realized, mean concentration of solution in generators can be effectively reduced, smaller compression ratio and higher injecting indexes can be acquired, and the jet typed sectional generating absorbing typed circulation has good energy-saving efficiency compared with the traditional heat supplying method.

Owner:刘辉

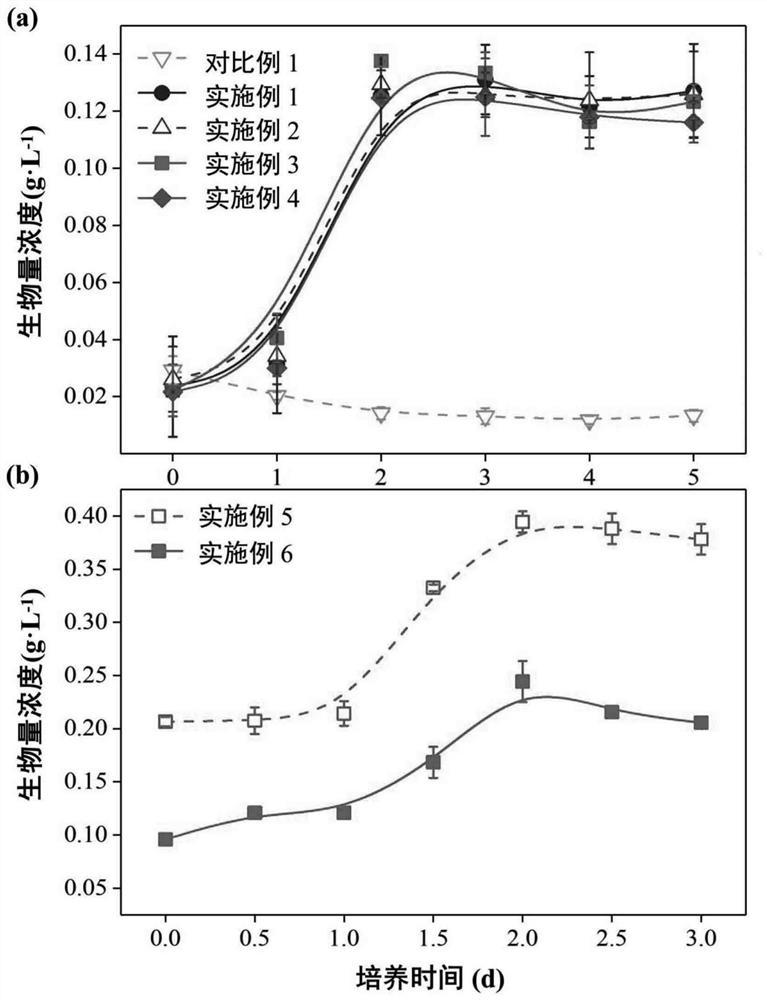

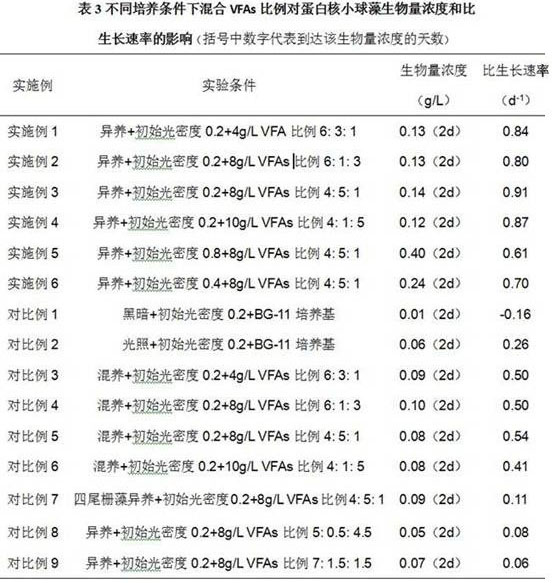

Method for promoting chlorella pyrenoidosa growth by using Volatile fatty acids

ActiveCN112457994AShort metabolic pathwayHigh theoretical lipid conversion efficiencyUnicellular algaeMicroorganism based processesBiotechnologyPropanoic acid

The invention belongs to the technical field of microalgae biology, and particularly relates to a method for promoting chlorella pyrenoidosa growth by using Volatile fatty acids. According to the present invention, a BG-11 culture medium is used as the base culture medium of chlorella pyrenoidosa, the algae liquid is subjected to centrifugal concentration when the microalgae grows to the logarithmic growth phase, 4-10g / L mixed Volatile Fatty Acids (VFAs) comprising acetic acid, propionic acid and butyric acid are added, the optical density value of the inoculated seed liquid at 680nm is 0.2-1.0, and the obtained material is placed at a temperature of 24-26 DEG C and is cultured for 2-5 days under a dark condition; and with the method, the growth period of heterotrophic chlorella pyrenoidosa can be significantly shortened, the microalgae can obtain the highest biomass concentration within two days, the rapid accumulation of biomass can be achieved, the conversion efficiency can be improved, the high culture cost problem caused by the too long culture period in the actual production can be reduced, and the new idea is provided for the large-scale production of oil production from microalgae.

Owner:QILU UNIV OF TECH

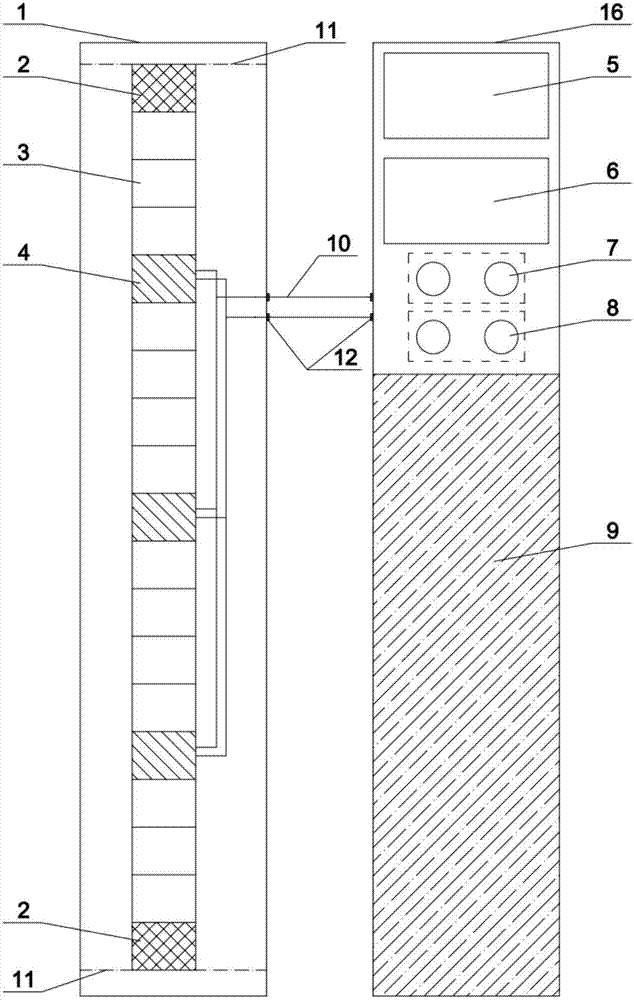

Modular data center

PendingCN107327996AEasy to transportQuick installationSpace heating and ventilation safety systemsLighting and heating apparatusData centerLow voltage

The invention discloses a modular data center. The modular data center comprises at least one first box body and at least one second box body, wherein the first box body is provided with an information equipment module and a power supply and distribution module, the information equipment module comprises cabinets, precise air conditioners and information devices arranged in the cabinets, and the power supply and distribution module comprises high-low-voltage conversion devices and uninterruptible power supplies which are arranged in power distribution cabinets; and the second box body is provided with a refrigeration module, and the refrigeration module comprises a double-working-condition cold water unit integrating mechanical refrigeration and natural cooling, an ice making unit, chilled water circulating pumps, cold storage and discharge pumps and an ice storage tank. According to the modular data center, the information equipment module and the refrigeration module are separately arranged in the independent box bodies, so that the transportation is convenient, and the installation is fast; and the double-working-condition cold water unit integrating mechanical refrigeration and natural cooling and the ice storage tank are adopted to realize deep utilization and gradient utilization of natural coldness resource, and the operation cost is greatly reduced by means of the peak load shifting effect of the ice storage tank.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

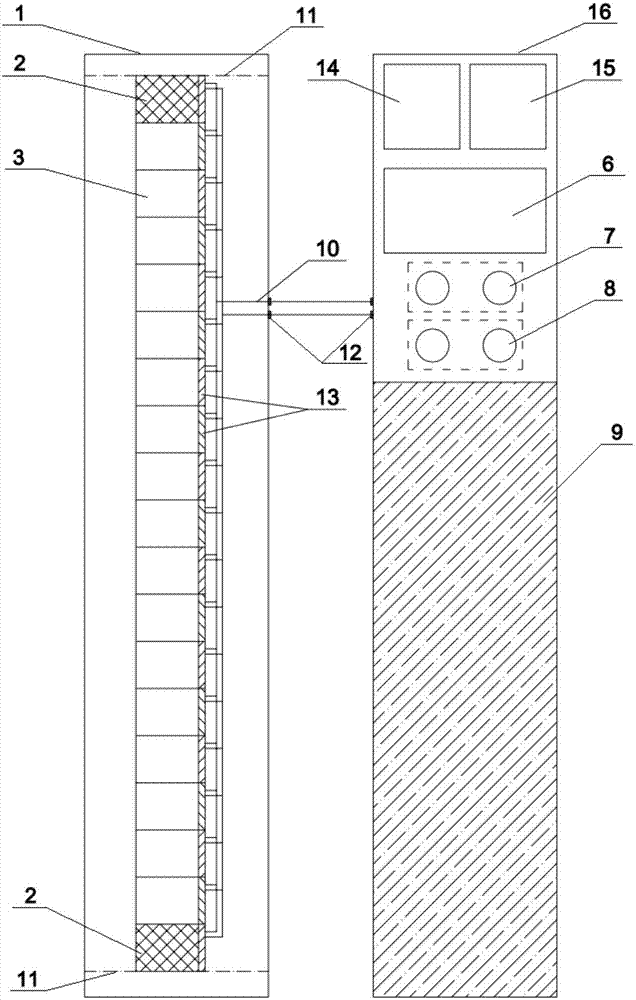

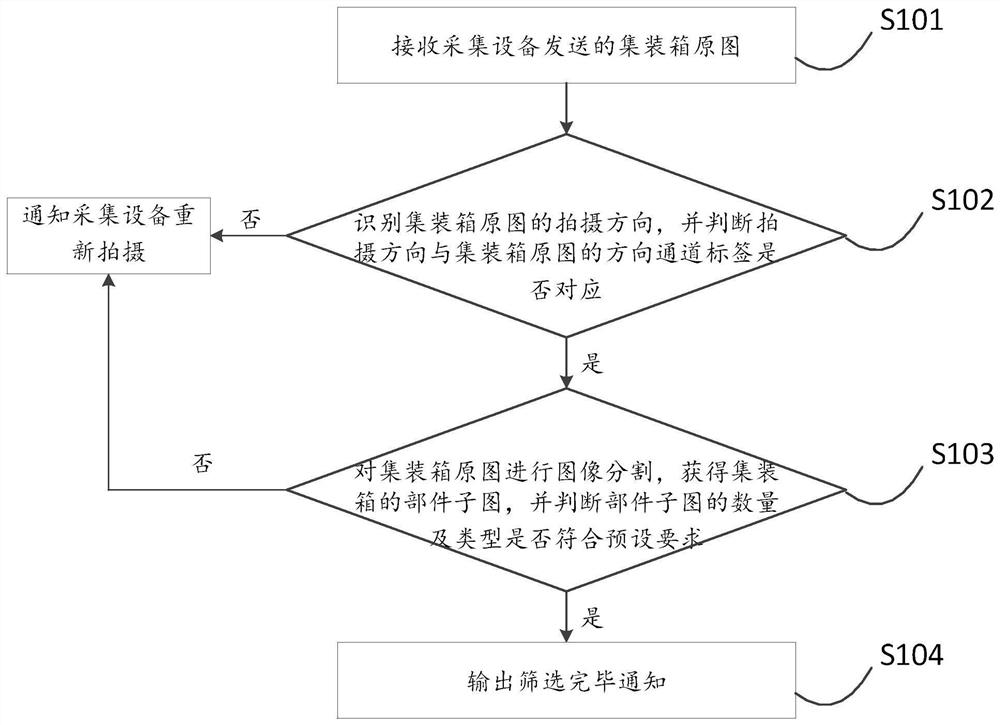

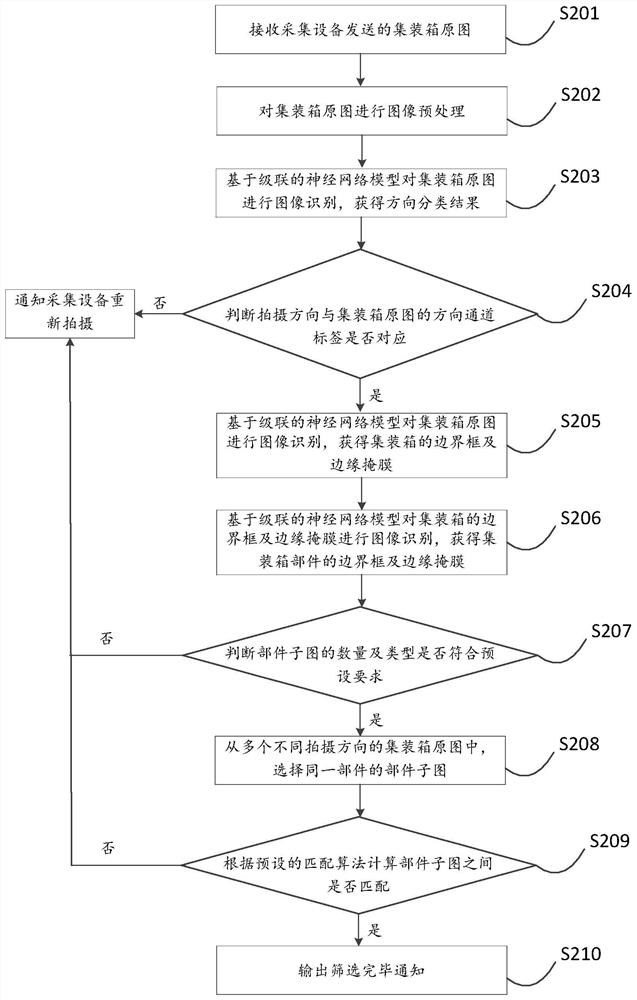

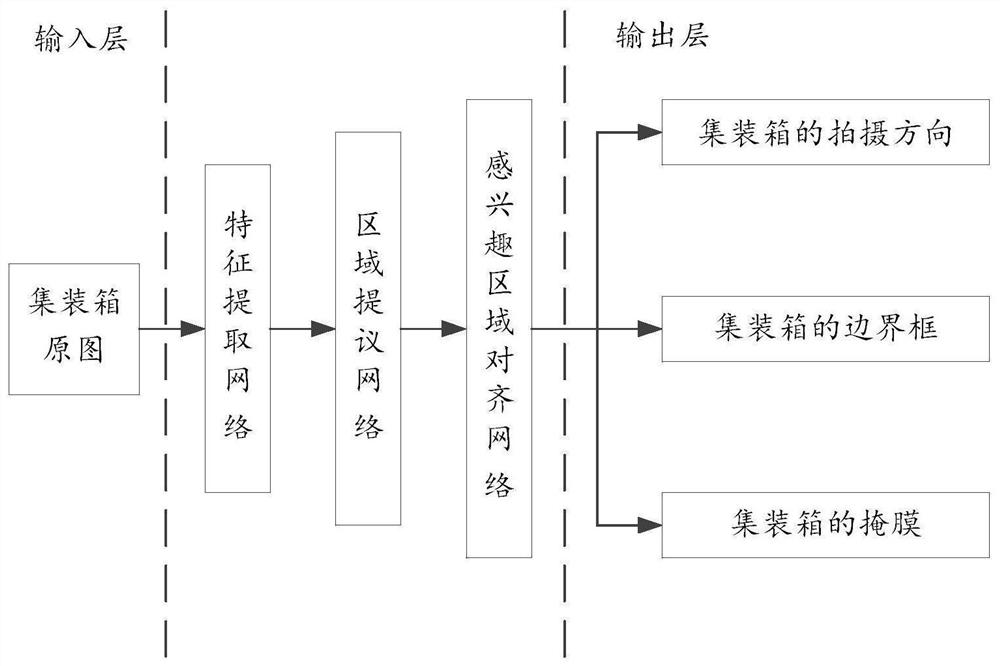

Container image screening method, computing equipment and storage medium

PendingCN111798446AImprove screening efficiencyPrevent over-occlusionImage enhancementImage analysisComputer graphics (images)Imaging quality

The invention discloses a container image screening method, computing equipment and a storage medium, relates to the technical field of automation, and aims to solve the problem of nonstandard container image acquisition. Shooting direction detection is carried out on an original container image collected in a non-fixed scene through an intelligent means, and the situation that images in the samedirection are transmitted in multiple times and a container body is excessively shielded is prevented. A cut image of container parts is obtained through an image segmentation technology, and the defect detection of the image part is carried out, so that the condition of part loss or incomplete shooting in the original image of the container is prevented, improper operations such as mistaken shooting and wrong shooting in the image acquisition process can be avoided, and standardized container body materials are provided for the subsequent container inspection link. The whole process is fullyautomatically realized, manual intervention is not needed, the image screening efficiency is improved, and the standardization of image quality can be ensured.

Owner:SHANGHAI QIAODONG NETWORK TECH CO LTD

System and method for simultaneously removing sulfur trioxide, ammonia gas, and fly ash in flue gas after SCR

ActiveCN109821409AGuaranteed uptimeGood temperingCombustion processDispersed particle separationAir preheaterFlue gas

The invention discloses a system and method for simultaneously removing sulfur trioxide, ammonia gas, and fly ash in flue gas after SCR. A rotary air preheater and an auxiliary flue gas conditioning system are taken as the basis of the system. The system mainly comprises the rotary air preheater, a flue gas online monitoring system, the auxiliary flue gas conditioning system, an electrostatic deduster, a flue gas deep cooler, and a pre-posed air heater. The heat exchange area of the rotary air preheater is reduced, the temperature of the flue gas outlet of the rotary air preheater is raised tothe dew point temperature of ammonium bisulfate or so, ammonia gas and sulfur trioxide in flue gas are used to modify flue gas; at the same time, the auxiliary flue gas conditioning system can adjustand optimize the flue gas conditioning process in real time according to the flue gas information provided by the flue gas online monitoring system. The provided simultaneous removal method can improve the dedusting efficiency of an electric deduster, is capable of removing sulfur trioxide and SCR escaped ammonia gas in flue gas, and solves the problem that a downstream heat-absorbing surface isobstructed and corroded by deposited ash.

Owner:XI AN JIAOTONG UNIV

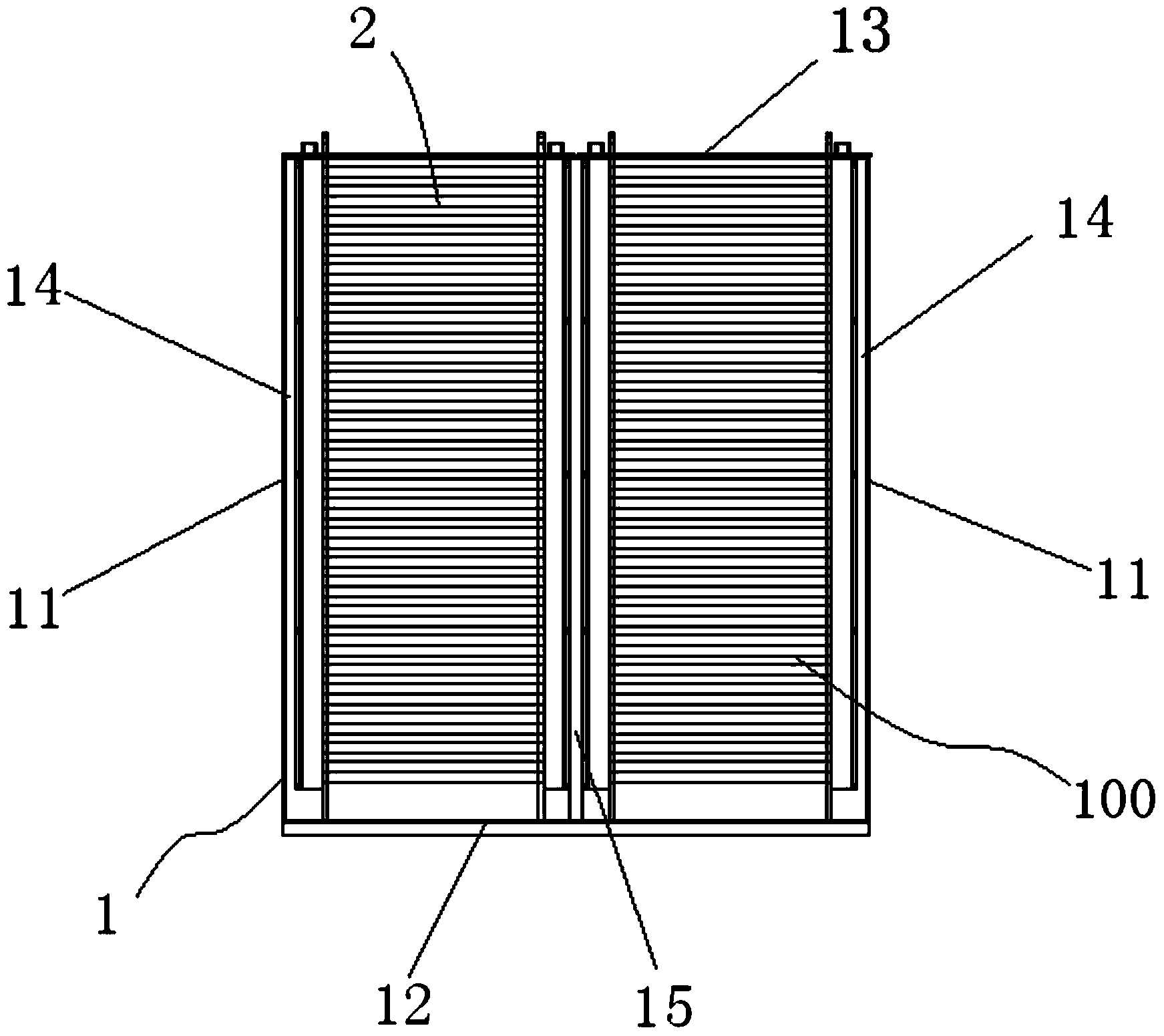

Grain drying system based on multi-fluid heat pipe

PendingCN111197928AReasonable structureIncrease profitDrying gas arrangementsIndirect heat exchangersWater storage tankEngineering

The invention relates to a grain drying system based on a multi-fluid heat pipe. The grain drying system based on the multi-fluid heat pipe comprises a dryer, a fresh air port, an evaporator, a condenser, a compressor and an expansion valve, wherein the dryer is connected to an air exhaust outlet through an air exhaust pipeline; the evaporation ends of a first multi-fluid heat pipe heat exchange device and a second multi-fluid heat pipe heat exchange device are arranged on the air exhaust pipeline; the evaporator is connected to a water storage tank; the condenser is arranged in an air supplypipe; the two ends of the compressor and the expansion valve are respectively connected to the condenser and the evaporator; and the condensation ends of the first multi-fluid heat pipe heat exchangedevice and the second multi-fluid heat pipe heat exchange device are arranged in the fresh air port. The multi-fluid heat pipe heat exchange devices are used for preheating fresh air. A multi-fluid sleeve type heat pipe is used for heating water flowing in a sleeve with the relatively low temperature, so that the heated water serves as a heat source of a water source heat pump; and the water source heat pump is used for reheating the preheated fresh air to meet the air inlet requirements of the grain dryer. The grain drying system improves the recovery utilization rate of the waste heat of exhaust air of the dryer, and can be used for drying food or seeds.

Owner:赛诺浦新能源(江苏)有限公司

Separation and extraction method for flavone function component in cowberry fruit residue waste

The invention discloses a separation and extraction method for a flavone function component in cowberry fruit residue waste. The method comprises the following steps: carrying out crushing, degreasing and drying on cowberry fruit residue to obtain powder; carrying out multiple extractions on the obtained powder with ethanol, and mixing the obtained filtrates; sequentially carrying out concentration, dissolving and centrifugation, and taking the supernatant; adding the obtained supernatant to a resin column to carry out absorption purification, and then carrying out elution; and carrying out recovery drying on the obtained eluent to obtain the finished product powder. The method has characteristics of fast absorption, high desorption rate, high adsorption capacity, high elution rate, simple resin regeneration, low cost, and the like, wherein a yield and purity of the obtained product are high, and the method is suitable for cowberry fruit residue deep utilization.

Owner:BAISHAN LINYUANCHUN ECOLOGY TECH

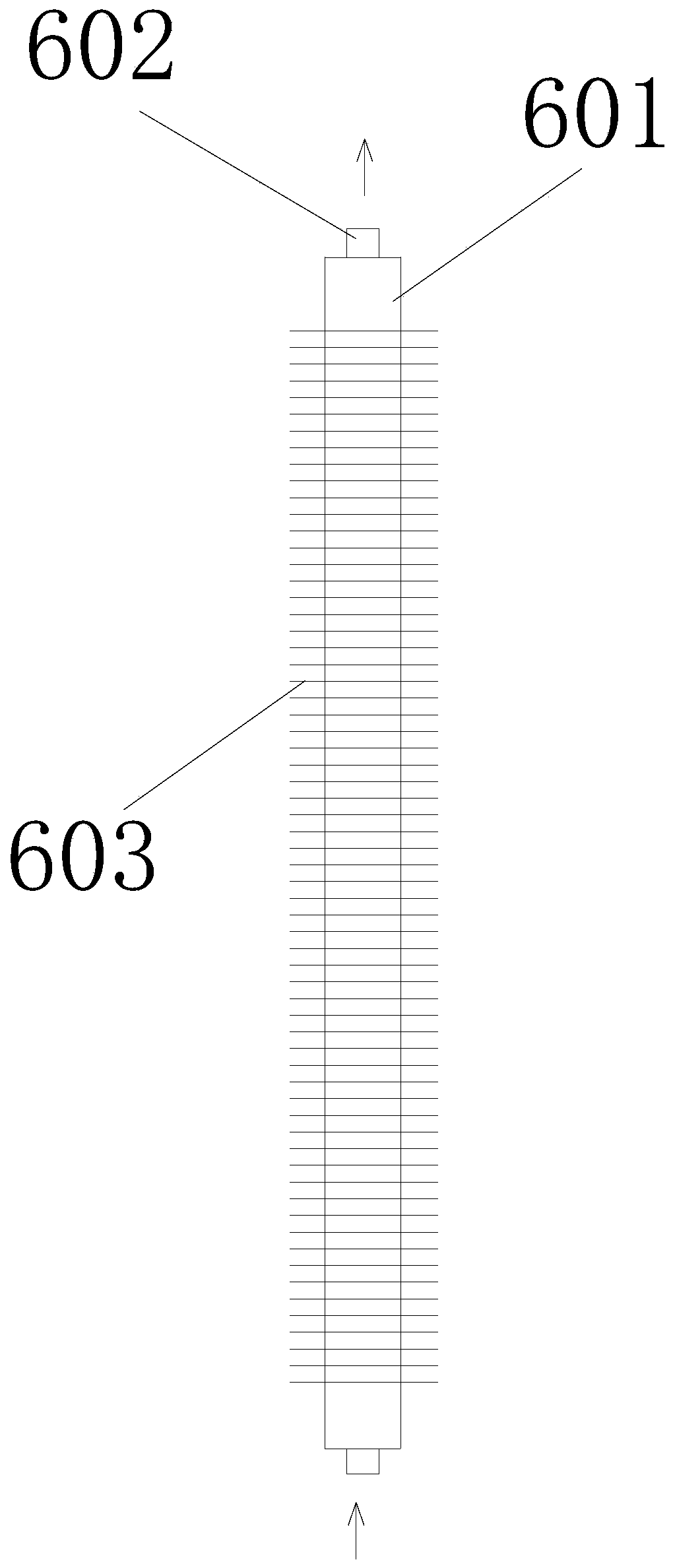

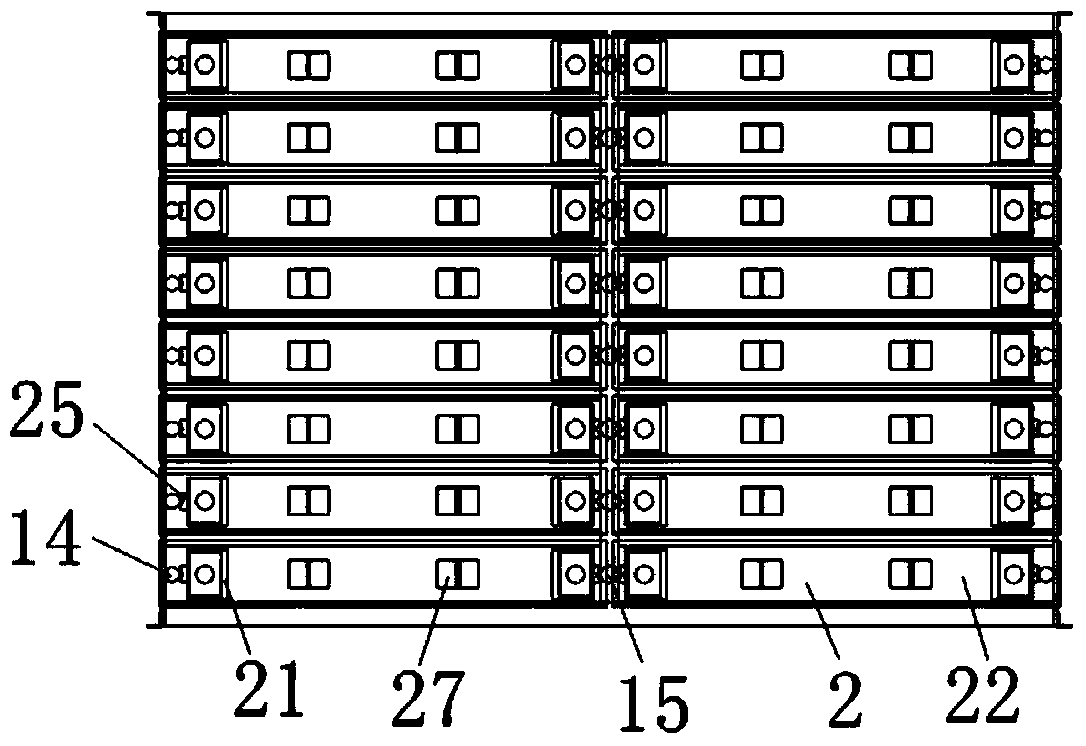

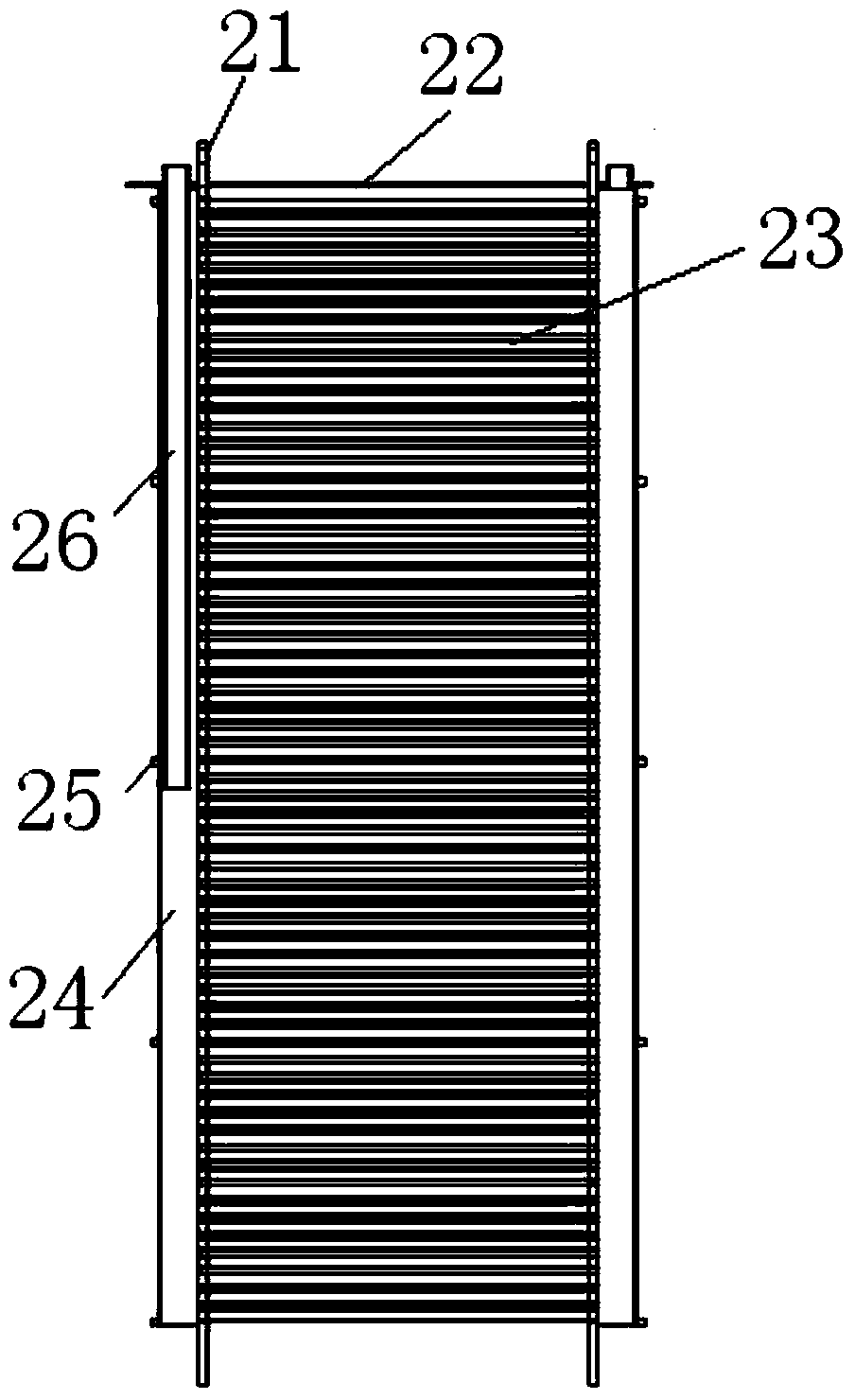

Smoke waste heat exchanger and recovery device

ActiveCN103884196AWear-resistantRealize deep utilizationEnergy industryCombustion technology mitigationMiddle lineCarbon steel

The invention relates to a smoke waste heat exchanger and recovery device for recovering kiln discharge smoke waste heat. The smoke waste heat exchanger comprises a shell body, a plurality of heat exchanging modules and a water supply-returning system. The shell body is arranged horizontally, openings in the two sides of the shell body are in a square cylinder shape, a plurality of vertically-arranged first sliding tracks are arranged at equal distance in the longitudinal direction on the inner wall of a side plate, and a plurality of vertically-arranged second sliding tracks are arranged at equal distance in the longitudinal direction between the middle line of the bottom plate and the middle line of the top plate. Each heat exchanging module comprises two pipe plates which are arranged vertically arranged at intervals and a module cover plate, the outer sides of the two pipe plates and groove type carbon steel are installed and welded to form water sleeves, the lower ends of the two water sleeves are sealed, the upper ends of the two water sleeves are openings, an opening of one water sleeve is a water inlet, an opening of the other water sleeve is a water outlet, a plurality of polished pipes which are arranged in parallel and are communicated with the water sleeves are connected between the two water sleeves, a plurality of sliding blocks are arranged on the outer sides of the two water sleeves at equal distance respectively, the heat exchanging modules are connected between the first sliding track and the second siding track collinear with the first sliding track through the sliding blocks on the two sides of the heat exchanging modules, water inlets of the heat exchanging modules are close to one side of the first sliding track, and water outlets of the heat exchanging modules are close to one side of the second sliding track.

Owner:北京中矿创智节能科技有限公司

A molten salt heat treatment system for waste incineration fly ash

ActiveCN107931301BEnough timePlenty of spaceSolid waste disposalTransportation and packagingSlagVolumetric Mass Density

The invention relates to the field of garbage incineration fly ash treatment, in particular to a garbage incineration fly ash molten salt heat treatment system. The waste incineration fly ash molten salt heat treatment system includes a raw material feeding system, a fly ash heat treatment system, a material discharge control system, a waste heat recovery system, and a flue gas purification system. The raw material feeding system includes molten salt storage bins, fly ash storage bins, and feeding devices; the fly ash heat treatment system includes reaction furnaces, electric heating rods, stirrers, and temperature controllers; the discharge control system includes liquid level sensors, density sensors, Constant temperature slag bag, centrifugal granulator, trap; waste heat recovery system includes heat transfer oil heat exchanger, thermal oil circulation pump and supporting pipelines; flue gas purification system includes induced draft fan and purification equipment. The invention revolves around the molten salt heat treatment of fly ash, realizes the resource recovery and detoxification treatment of fly ash simultaneously, and promotes the energy saving and emission reduction of the fly ash heat treatment process and the deep resource utilization of products through tail gas purification, intelligent slag discharge and slag waste heat recovery use.

Owner:HUAZHONG UNIV OF SCI & TECH

Different grade composite first kind absorption heat pump

ActiveCN101182961BImprove performance indexWide heating temperature rangeHeat pumpsEnergy efficient heating/coolingComing outEvaporation

The invention provides a different-level compound first class absorption-typed heat pump and belongs to the technical field of waste heat utilization and heat pump / refrigeration. The invention aims atthe shortcoming of a single class heat pump and provides an integrated machine set consisting of a generator, a condenser, an absorber, an evaporator, an absorption-evaporation device, a throttle valve, a solution pump and other basic components; the invention is divided into three types respectively with a common evaporator, a common condenser or no common component; the processes of the heat pump in different levels are compounded through the evaporator or the condenser and / or waste heat medium channel simply while accompanied by other components; when sharing the evaporator, each condenser is interconnected through the throttle valve or is separated from each other or is separated partly; when under other conditions, waste heat medium enters into and comes out of each evaporator in sequence; refrigerant medium from the condenser enters into the evaporator and the absorption-evaporation device through the throttle valve and is absorbed by solution at each associated connection; diluted solution releases refrigerant into the condenser with the action of driven heat. The heat pump can take use of waste heat and refrigeration with waste heat has high benefit.

Owner:李华玉

System and method for synergistic removal of sulfur trioxide, ammonia and fly ash in SCR flue gas

ActiveCN109821409BGood temperingImprove removal efficiencyCombustion processDispersed particle separationAir preheaterDust control

The invention discloses a system and method for simultaneously removing sulfur trioxide, ammonia gas, and fly ash in flue gas after SCR. A rotary air preheater and an auxiliary flue gas conditioning system are taken as the basis of the system. The system mainly comprises the rotary air preheater, a flue gas online monitoring system, the auxiliary flue gas conditioning system, an electrostatic deduster, a flue gas deep cooler, and a pre-posed air heater. The heat exchange area of the rotary air preheater is reduced, the temperature of the flue gas outlet of the rotary air preheater is raised tothe dew point temperature of ammonium bisulfate or so, ammonia gas and sulfur trioxide in flue gas are used to modify flue gas; at the same time, the auxiliary flue gas conditioning system can adjustand optimize the flue gas conditioning process in real time according to the flue gas information provided by the flue gas online monitoring system. The provided simultaneous removal method can improve the dedusting efficiency of an electric deduster, is capable of removing sulfur trioxide and SCR escaped ammonia gas in flue gas, and solves the problem that a downstream heat-absorbing surface isobstructed and corroded by deposited ash.

Owner:XI AN JIAOTONG UNIV

Method for manufacturing light ceramisite through high-sulfur coal gangue tailings

InactiveCN107082585AHigh strengthImprove plasticitySolid waste managementWet separationResource utilizationSlag

The invention discloses a method for manufacturing light ceramisite through high-sulfur coal gangue tailings. The method comprise the following steps of step 1 of weighing raw materials according to parts by weight: 45 to 65 parts of kaolinite tailings, 20 to 30 parts of steel slag and 5 to 10 parts of coal slime; step 2 of ball milling and evenly mixing the raw materials to obtain a mixed material which has a particle size of 230 to 270 meshes; the step 3 of adding 15 to 20 parts of water into the mixed material, then utilizing a disc granulator to perform balling treatment to obtain a ball material, wherein the diameter of the ball material is 8 to 10mm; step 4 of preheating the ball material; step 5 of sintering the preheated ball material at high temperature and cooling to obtain the light ceramisite; the kaolinite tailings are high-sulfur coal gangue obtained through hydrocyclone separation and floatation. The method disclosed by the invention improves resource utilization of the high-sulfur coal gangue and the steel slag, further is simple in processing technology, reduces environmental pollution and meanwhile greatly improves added value space of the high-sulfur coal gangue and the steel slag.

Owner:绵阳耀邦环保科技有限公司

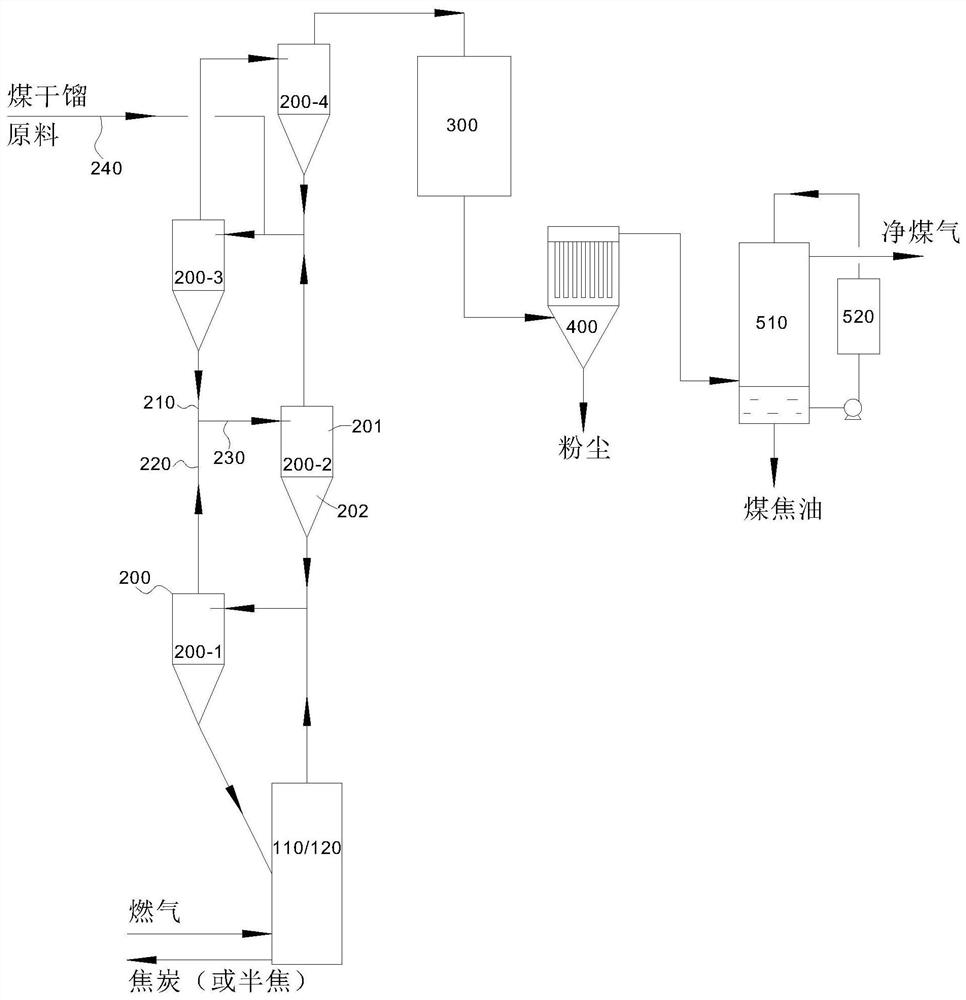

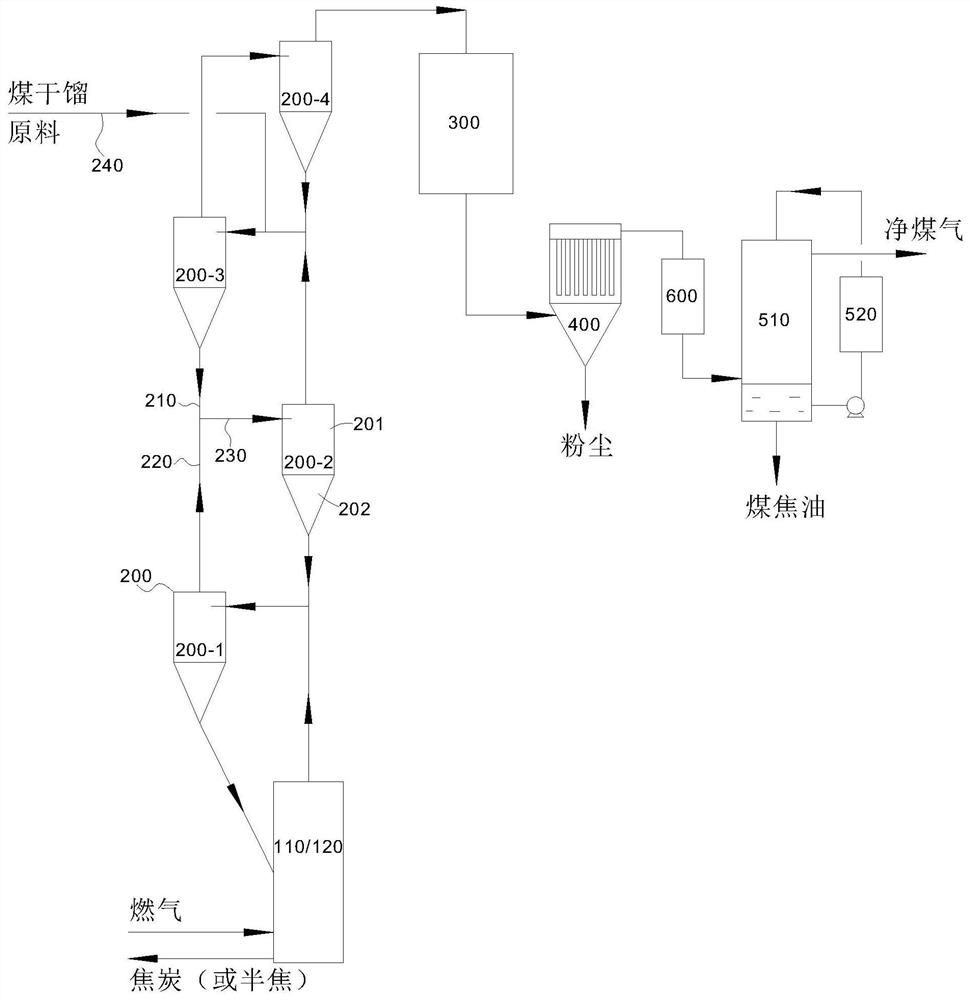

Treatment method of high-temperature dry distillation raw gas

ActiveCN114106890AAchieving High Value RecyclingRealize deep utilizationGas purification by non-gaseous materials condensationGas contaminants removalGas solidThermodynamics

The invention discloses a treatment method of high-temperature dry distillation raw gas, and solves the technical problem that the high-temperature dry distillation raw gas is not fully and efficiently treated in the prior art. The treatment method of the high-temperature dry distillation raw gas comprises the following steps: (1) carrying out pre-decomposition reaction and pre-dedusting on the raw gas from a coal dry distillation rotary kiln or a coal dry distillation furnace and a coal dry distillation raw material, and outputting first gas and solid; (2) drying the first gas, and outputting second gas; (3) carrying out gas-solid separation treatment on the second gas, and outputting third gas; and (4) condensing the third gas, and outputting coal tar and clean gas.

Owner:CHENGDU INTERMENT TECH

Absorption type grading heat supply system

ActiveCN102410575BAdjustable heating loadRealize deep utilizationEnergy efficient heating/coolingClimate change adaptationProcess engineeringRefrigeration

The invention provides an absorption type grading heat supply system, belonging to the technical field of waste heat utilization and heat pump / refrigeration. A first generator, a first absorber, a first condenser, a first evaporator, a first solution pump, a first throttle valve, a first solution heat exchanger, a newly-added generator, a newly-added absorber, a newly-added solution pump and a newly-added solution heat exchanger form a primary heat medium heating process; a second generator, a third generator, a second absorber, a third absorber, a second condenser, a second evaporator, a second solution pump, a third solution pump, a second throttling valve, a second solution heat exchanger and a third solution heat exchanger form a secondary heat medium heating process; and a primary heat medium flows through the secondary heat medium heating process and provides a drive heat load and a low-temperature heat load, and a circulating pump realizes primary heat medium circulating flowing. Corresponding parts are additionally provided, thus a series of absorption type grading heat supply systems are obtained.

Owner:李华玉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com