Method and device for cooperatively enhancing PM2.5 (Particulate Matter 2.5) removal and smoke afterheat deep utilization

A flue gas waste heat and removal technology, which is applied in the field of energy saving and emission reduction of industrial boilers and coal-fired power plant boilers, to achieve the effects of reducing the amount of flue gas under working conditions, increasing the moisture content of flue gas, and promoting the improvement of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

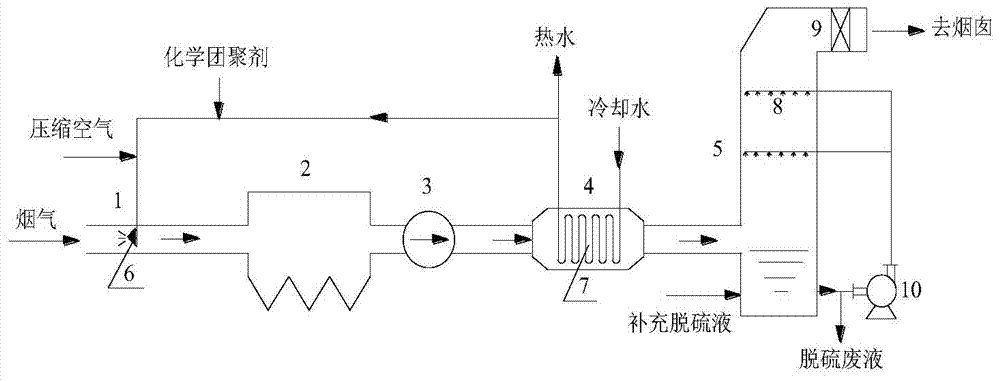

Image

Examples

Embodiment 1

[0026] The flue gas is produced by a fully automatic coal-fired boiler with a flue gas volume of 300Nm 3 / h, supplemented by a SAG-410 aerosol generator to add an appropriate amount of coal-fired fly ash to the flue gas, so that the dust concentration in the coal-fired flue gas is 4850mg / m 3 , where PM 2.5 The concentration is 172mg / m 3 . Along the flue gas flow direction, there are flue gas humidification devices, electrostatic precipitators, low-temperature economizers, and limestone / gypsum flue gas desulfurization systems. The electrostatic precipitator has a three-electric field structure, the cathode is a conventional acupuncture electrode, and the distance between the plates is 0.30m. The low-temperature economizer heat exchange tubes are made of finned tubes and ND corrosion-resistant steel. The wet desulfurization tower adopts a spray tower with a tower diameter of 200mm and a tower height of 4500mm, and a baffle demister is installed on the top of the spray tower....

Embodiment 2

[0028] Add polyferric sulfate and polyether modified silicone to the atomized hot water sprayed into the flue gas humidification device to make a chemical agglomeration agent solution. The mass percentage composition of the agglomeration agent solution is: 0.05% polyferric sulfate, 0.005% poly Ether modified silicone, all the other are the same as in Example 1. Tested by the WJ-60B pitot tube parallel automatic smoke sampler, the dust concentration at the outlet of the electrostatic precipitator and the outlet of the desulfurization tower is 37mg / m3 3 、13mg / m 3 ; Among them, the electric low-voltage impactor ELPI online test is used, and the outlet of the electrostatic precipitator and the outlet of the desulfurization tower are PM 2.5 The mass concentration is 12mg / m 3 , 5mg / m 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com