Special carrier-free colored plastic high-gloss modified master batch

A carrier-free, color technology, applied in the field of plastic material preparation, can solve the problems of low molecular weight, reduced surface hardness and gloss of blended plastics, etc., and achieve the effect of promoting agglomeration and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

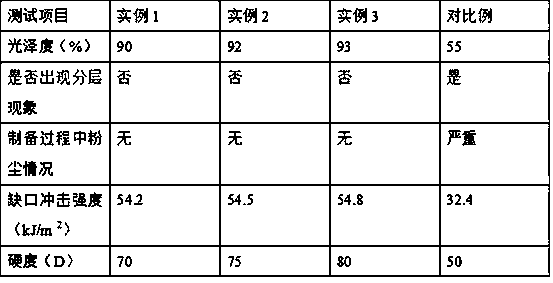

Examples

example 1

[0025]In a three-necked flask equipped with a thermometer, a stirrer, and a reflux device, add palm oil and diethanolamine at a mass ratio of 1:2, react at a temperature of 150°C for 2 hours, then lower the temperature to 70°C, and add palm oil with a content of 1.0 double the amount of diethanolamine, continue to react for 3h to obtain a brown viscous transparent liquid, which turns into a white solid after natural cooling; under a nitrogen atmosphere, take 40 parts of the above white solid, 1 part of stearic acid and 0.5 part of ethylene glycol, place In a four-necked flask, heat up to 160°C, mix and react for 4 hours at a stirring speed of 600r / min, and prepare a lubricating dispersant; in parts by weight, 8 parts of glaze powder, 30 parts of albite, 20 parts of albite One part of potassium feldspar, 40 parts of hydroxy silicone oil emulsion with a mass fraction of 20% were placed in a mixer and stirred at a speed of 100r / min for 30 minutes to obtain a mixed stone slurry, 30...

example 2

[0027] In a three-necked flask equipped with a thermometer, a stirrer, and a reflux device, add palm oil and diethanolamine at a mass ratio of 1:2, react at a temperature of 160°C for 2.5 hours, then cool down to 75°C, and add palm oil content 1.2 times of diethanolamine, continue to react for 3.5h to obtain a brown viscous transparent liquid, which turns into a white solid after natural cooling; under a nitrogen atmosphere, take 45 parts of the above white solid, 3 parts of stearic acid and 2.5 parts of ethylene glycol, Place in a four-necked flask, heat up to 200°C, mix and react at a stirring speed of 700r / min for 4.5h, and prepare a lubricating dispersant; in parts by weight, mix 9 parts of glaze powder, 35 parts of sodium long Stone, 25 parts of potassium feldspar, 45 parts of hydroxy silicone oil emulsion with a mass fraction of 20% were placed in a mixer and stirred at a speed of 110r / min for 35 minutes to obtain a mixed stone slurry, 35 parts of manganese slag, 75 parts...

example 3

[0029] In a three-necked flask equipped with a thermometer, a stirrer, and a reflux device, add palm oil and diethanolamine at a mass ratio of 1:2, react at a temperature of 170°C for 3 hours, then lower the temperature to 80°C, and add palm oil with a content of 1.5 double the amount of diethanolamine, continue to react for 4h to obtain a brown viscous transparent liquid, which turns into a white solid after natural cooling; under a nitrogen atmosphere, take 50 parts of the above white solid, 5 parts of stearic acid and 4.0 parts of ethylene glycol, place In a four-necked flask, heat up to 220°C, mix and react for 5 hours at a stirring speed of 800r / min, and prepare a lubricating dispersant; in parts by weight, 10 parts of glaze powder, 40 parts of albite, 30 parts of albite One part of potassium feldspar, 50 parts of hydroxy silicone oil emulsion with a mass fraction of 20% were placed in a mixer and stirred at a speed of 120r / min for 40 minutes to obtain a mixed stone slurry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com