Technology of synthesizing nano bismuth stearate by liquid phase dispersing process

A liquid phase dispersion method, stearic acid technology, applied in the direction of nanotechnology, nanotechnology, nanostructure manufacturing, etc., to achieve the effect of large coverage, promotion of ulcer healing, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

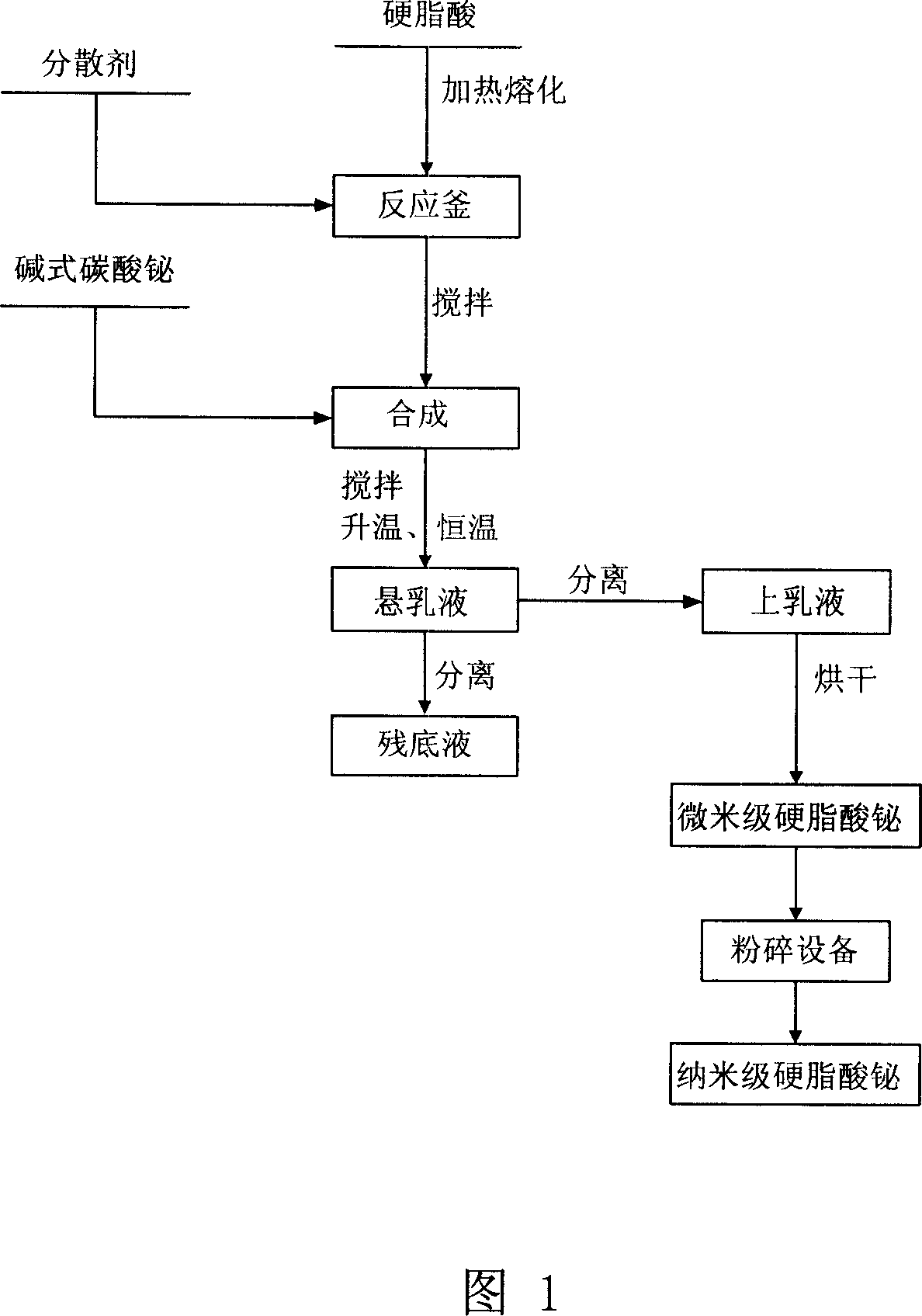

[0031] A process for synthesizing nano-bismuth stearate by a liquid phase dispersion method. The process flow is as follows:

[0032] (1) Add stearic acid to the reaction kettle and heat at normal pressure to increase the temperature by 70~88℃ to melt;

[0033] (2) Take 1% of the dispersant-edible glycerol according to the added amount of stearic acid and mix it into the reaction kettle, mix and stir for 15 minutes;

[0034] (3) Under the condition of continuous stirring, slowly add metered bismuth subcarbonate, heat it to 100-102°C, keep the temperature constant, control the reaction time for 40-70 minutes, and synthesize bismuth stearate suspension emulsion;

[0035] Among them, the amount of bismuth subcarbonate added should be controlled at the theoretical demand G. The weight G of the unit weight of stearic acid and the added bismuth substearate is calculated as follows:

[0036] G=[H×M×(1.01~1.02)] / 56.1×100×2×X

[0037] In the formula: the acid value of H-stearic acid, mgKOH...

Embodiment 2

[0044] A process for synthesizing nano-bismuth stearate by a liquid phase dispersion method is characterized in that the process flow is carried out as follows:

[0045] (1) Add stearic acid to the reaction kettle and heat at normal pressure to increase the temperature by 75-85°C to melt;

[0046] (2) Take 0.5% isopropanol according to the added amount of stearic acid and mix it into the reactor, mix and stir for 10 minutes;

[0047] (3) Under the condition of constant stirring, slowly add metered bismuth subcarbonate, heat to 100-102°C, keep constant temperature, control the reaction time for 55-75 minutes, and synthesize bismuth stearate suspension emulsion;

[0048] Among them, the amount of bismuth subcarbonate added should be controlled at the theoretical demand G. The weight G of the unit weight of stearic acid and the added bismuth substearate is calculated as follows:

[0049] G=[H×M×(1.01~1.02)] / 56.1×100×2×X

[0050] In the formula: the acid value of H-stearic acid, mgKOH...

Embodiment 3

[0057] A process for synthesizing nano-bismuth stearate by a liquid phase dispersion method is characterized in that the process flow is carried out as follows:

[0058] (1) Add stearic acid to the reaction kettle and heat at normal pressure to increase the temperature to 85~90℃ to melt;

[0059] (2) Take 0.8% sorbitol based on the added amount of stearic acid and mix it into the reactor, mix and stir for 20 minutes;

[0060] (3) Under the condition of constant stirring, slowly add metered bismuth subcarbonate, heat to 100-102°C, keep constant temperature, control the reaction time for 60-80 minutes, and synthesize bismuth stearate suspension emulsion;

[0061] Among them, the amount of bismuth subcarbonate added should be controlled at the theoretical demand G. The weight G of the unit weight of stearic acid and the added bismuth substearate is calculated as follows:

[0062] G=[H×M×(1.01~1.02)] / 56.1×100×2×X

[0063] In the formula: the acid value of H-stearic acid, mgKOH / g;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com