Device for efficiently removing SO3 in flue gas after wet desulphurization

A wet desulfurization and flue gas technology, applied in the field of flue gas treatment, can solve the problems of high investment and operation costs, complex technical system, unstable removal efficiency, etc., to reduce investment costs and operating costs, enhance removal effect, The effect of increased contact chance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

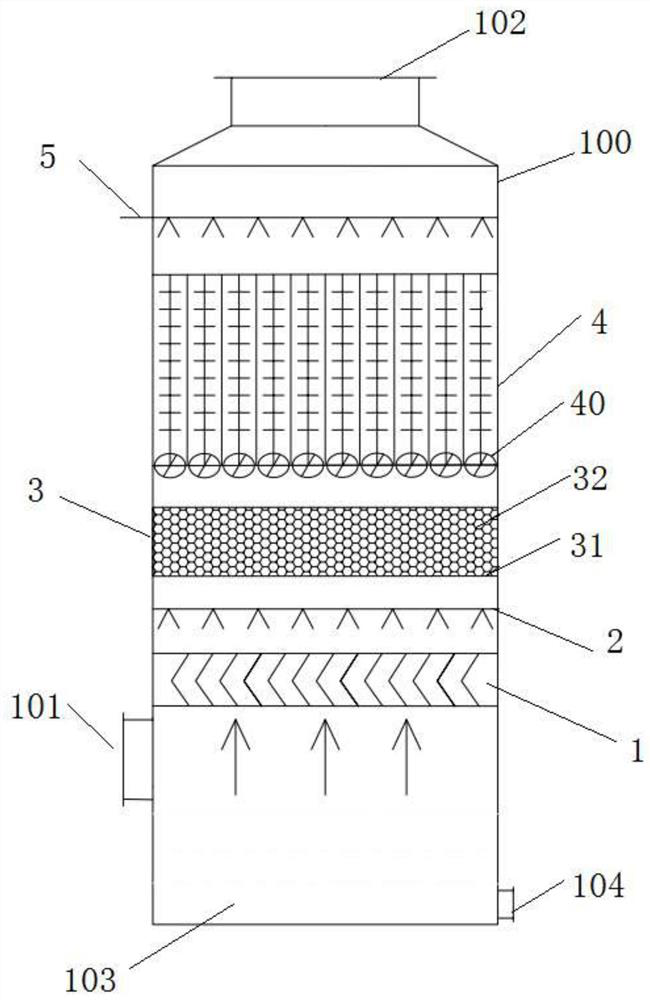

[0057] Embodiment 1, a method for SO in flue gas after wet desulfurization 3 High-efficiency removal device, as an independent reactor:

[0058] Including the cylindrical tower body 100, since the cylindrical tower body 100 has a bottom surface, the bottom inner cavity of the cylindrical tower body 100 is used as a liquid collection pool 103, and is arranged on the side wall of the cylindrical tower body 100 corresponding to the liquid collection pool 103 There is a liquid outlet 104; a flue gas inlet 101 is arranged on the side wall near the bottom of the cylindrical tower body 100, and the flue gas inlet 101 is located above the liquid collection tank 103 (that is, above the liquid outlet 104); the flue gas inlet 101 is inclined downward by 5-10°.

[0059] A flue gas outlet 102 is provided on the top of the cylindrical tower body 100 , so the flue gas inlet 101 and the flue gas outlet 102 are both connected to the inner cavity of the cylindrical tower body 100 .

[0060] A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com