Processing method capable of synergistically reducing digestion and aging properties of starch

A technology of aging performance and processing method, which is applied in the field of food, can solve problems such as lack, and achieve the effects of improved ordering, high controllability, reduced digestibility and aging retrograde characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

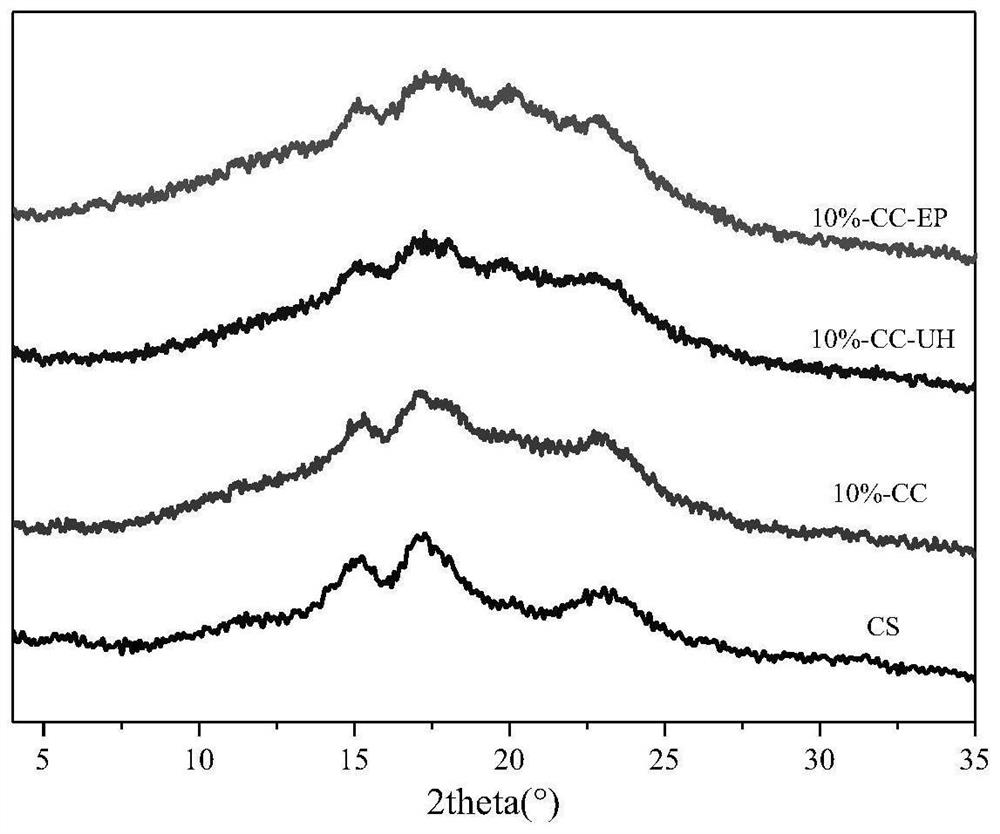

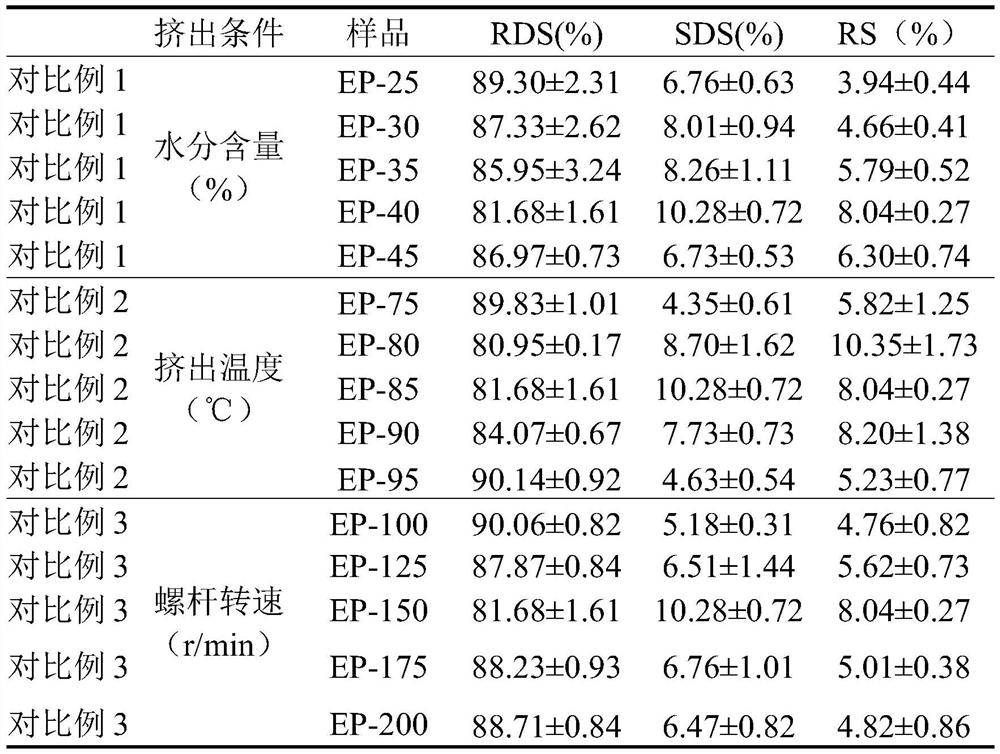

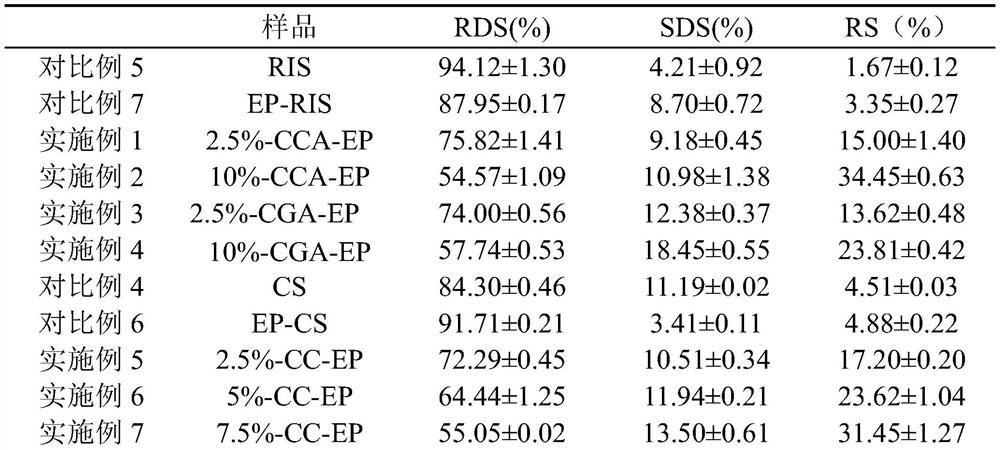

[0030]Weigh certain amount of rice starch, caffeic acid and water by mass fraction, first dissolve the caffeic acid in anhydrous ethanol (two times the number of waterless ethanol mass parts is twice the number of caffeic acid), and then add the moisture content Uniform mixing in rice starch such that the caffeic acid content is 2.5% of the starch dry group mass, and the moisture content is 40% of the mass of the starch. Extrusion treatment is performed under conditions of the extrusion temperature of 80 ° C, the screw speed is 150 r / min. The extruded starch sample was then lyophilized for 36 hours after 36 hours, and the sieve was pulverized. Determination of the digestive properties and returning properties of these extruded large rice starch samples. The measurement results are shown in Table 2, and Table 3 shows.

Embodiment 2

[0032]Weigh a certain amount of rice starch, caffeic acid and water according to the mass fraction, first dissolve the caffeic acid in anhydrous ethanol (the number of anhydrous ethanol mass parts is twice the number of caffeic acid mass), then join the moisture content Uniform mixing in rice starch such that the caffeic acid content is 10% of the starch dry group mass, and the moisture content is 40% of the starch dry group mass. Extrusion treatment is performed under conditions of the extrusion temperature of 80 ° C, the screw speed is 150 r / min. The extruded starch sample was then lyophilized for 36 hours after 36 hours, and the sieve was pulverized. Determination of the digestive properties and returning properties of these extruded large rice starch samples. The measurement results are shown in Table 2, and Table 3 shows.

Embodiment 3

[0034]Weigh a certain amount of rice starch, chlorogenic acid and water according to the mass fraction, first dissolve the chlorogenic acid in anhydrous ethanol (the number of waterless ethanol mass parts is twice the number of chlorogenic parts), then join the adjusted Mix mixed in rice starch in a moisture content such that the chlorogenic acid content is 2.5% of the starch dry group mass, and the moisture content is 40% of the mass of the starch dry group. Extrusion treatment is performed under conditions of the extrusion temperature of 80 ° C, the screw speed is 150 r / min. The extruded starch sample was then lyophilized for 36 hours after 36 hours, and the sieve was pulverized. Determination of the digestive properties and returning properties of these extruded large rice starch samples. The measurement results are shown in Table 2, and Table 3 shows.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com