A solid-liquid phase change heat storage device based on air heat exchange

A technology of air heat exchange and phase change heat storage, applied in the direction of indirect heat exchangers, heat exchanger types, heat storage equipment, etc. , selection of container materials and other issues to achieve the effect of simple structure, stable charge and discharge heat, and increased contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

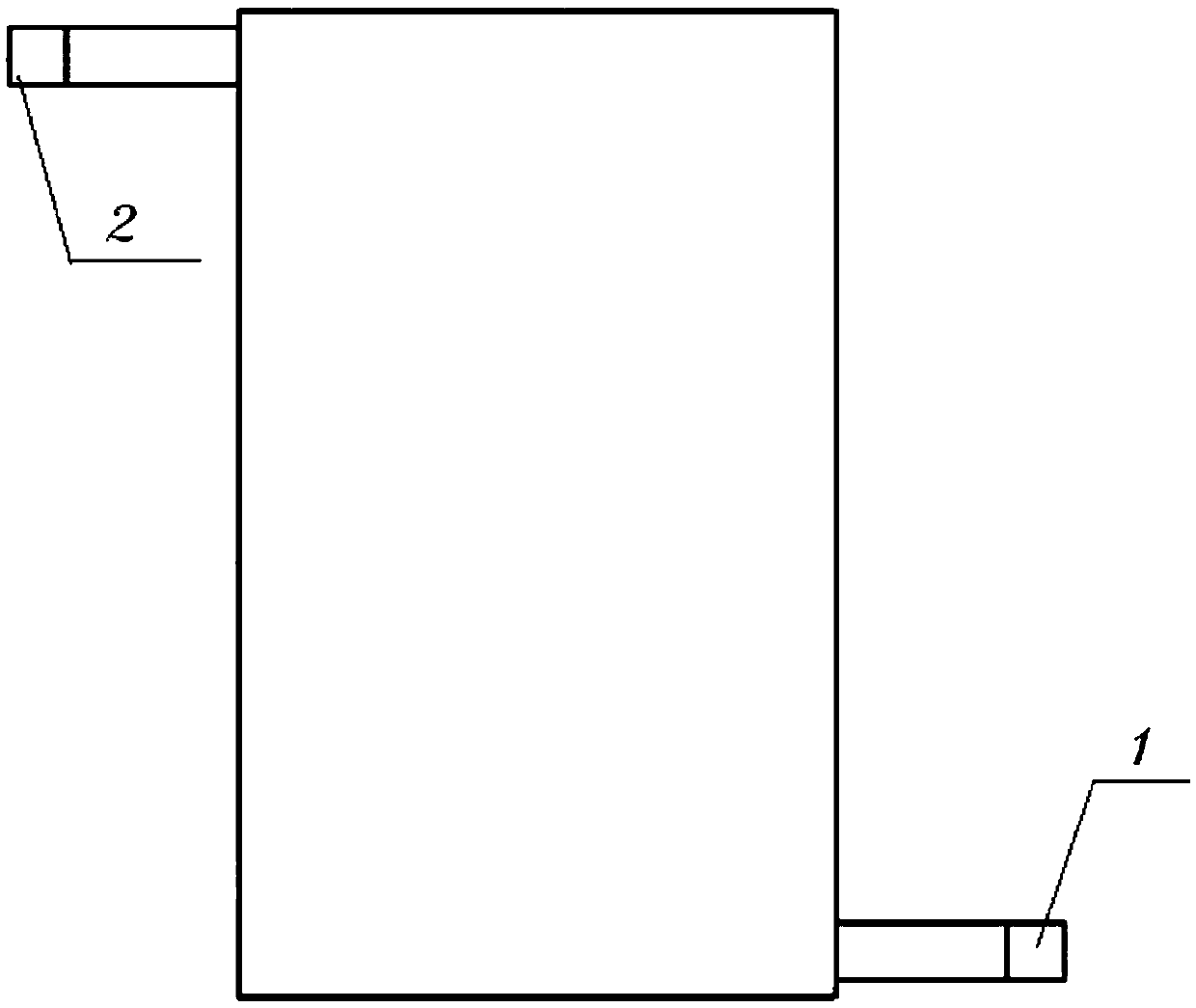

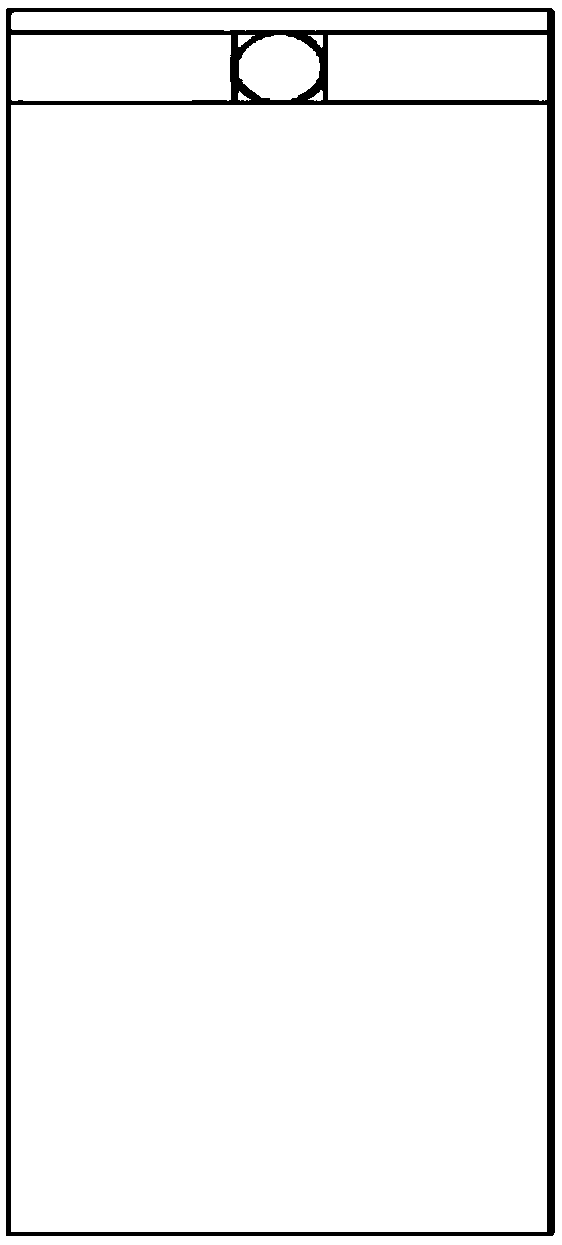

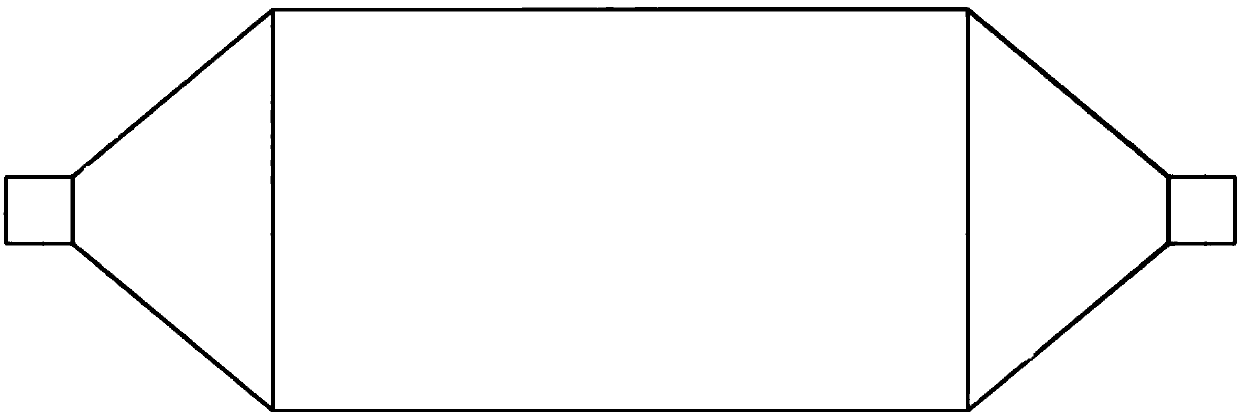

[0031] as attached Figure 1-3 and Figure 6 As shown, a solid-liquid phase change heat storage device based on air heat exchange includes a heat storage box 5 and a phase change heat storage unit 6. The heat storage box 5 is provided with a heat exchange medium inlet 1 and a heat exchange medium. The medium outlet 2 is connected with the internal space of the heat storage box 5; the phase change heat storage unit 6 includes a heat storage material container 7 and a phase change heat storage material 3, and the phase change heat storage material 3 is packaged in the heat storage material Inside the container 7 ; the phase change heat storage unit 6 is placed in the heat storage box 5 .

[0032] Such as Figure 4As shown, the heat storage box 5 is provided with 8 phase change heat storage units 6, each heat storage unit 6 is independent of each other, and the total volume of the 8 phase change heat storage units 6 accounts for 70% of the volume of the heat storage box 5. ~80...

Embodiment 2

[0040] This embodiment is basically the same as Embodiment 1, except that: the solid-liquid phase change heat storage material selects a high-temperature heat storage alloy: Mg-53% Zn eutectic alloy; at the same time, the heat storage material contains the container and the heat storage box Choose 304 stainless steel.

[0041] The measurement results of differential scanning calorimeter (DSC) show that the phase transition temperature and latent heat of phase transition of Mg-53% Zn eutectic alloy are 343°C and 165kJ / Kg respectively, and the heat storage density is 458.7MJ / m 3 Be 99.99% Mg, 99.99% Zn metal with purity to prepare Mg-53% Zn alloy, calculate the alloy ratio according to 12wt% Mg burning loss, after the smelting furnace is heated up to 680 ℃ to magnesium melting completely, then add Zn, cool down to 500°C, keep warm for 10 minutes, pour into the heat storage container to cool, and finally completely seal it into the heat storage box and put it into use. Before put...

Embodiment 3

[0043] It is basically the same as that of Example 1, except that the low-temperature phase change material: stearic acid is selected as the solid-liquid phase change heat storage material; 304 stainless steel is selected as the container for the heat storage material.

[0044] The measurement results of differential scanning calorimeter (DSC) show that the phase transition temperature and latent heat of phase transition of stearic acid are 70°C and 220kJ / Kg respectively, and the heat storage density is 191.4MJ / m 3 ; Stearic acid is suitable for low-temperature heat storage, the maximum operating temperature is 200°C, the heat storage capacity of a single heat storage box is 21.17MJ, and the heat exchange efficiency between the air in the heat storage box and the heat storage unit is above 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com