A g-c3n4/al2o3/zno heterojunction with visible light catalytic activity and its preparation method

A catalytic activity, g-c3n4 technology, applied in the field of g-C3N4/Al2O3/ZnO heterojunction and its preparation, can solve problems such as low quantum efficiency, and achieve the effects of simple preparation process, wide application and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Follow the steps below to prepare g-C 3 N 4 / Al 2 o 3 / ZnO ternary heterojunction (the sample is marked as 50C / 40A / 10Z):

[0043] ①Dissolve 0.0047mol of aluminum nitrate in distilled water, then add 0.3g of g-C prepared in the laboratory 3 N 4 (see below for the preparation process), after stirring evenly, add 1 mol / L NaOH solution dropwise to the beaker until pH=8-9, and continue stirring for 1 hour;

[0044] ②Dissolve 0.00072mol of zinc nitrate in distilled water, drop it into the turbid solution prepared in step ① simultaneously with 1mol / L NaOH solution, keep the pH=8-9, and continue to stir for 1 hour.

[0045] ③ Suction filter, dry and grind the precipitate obtained in ② to obtain the precursor, which is calcined at 400°C to obtain the desired sample.

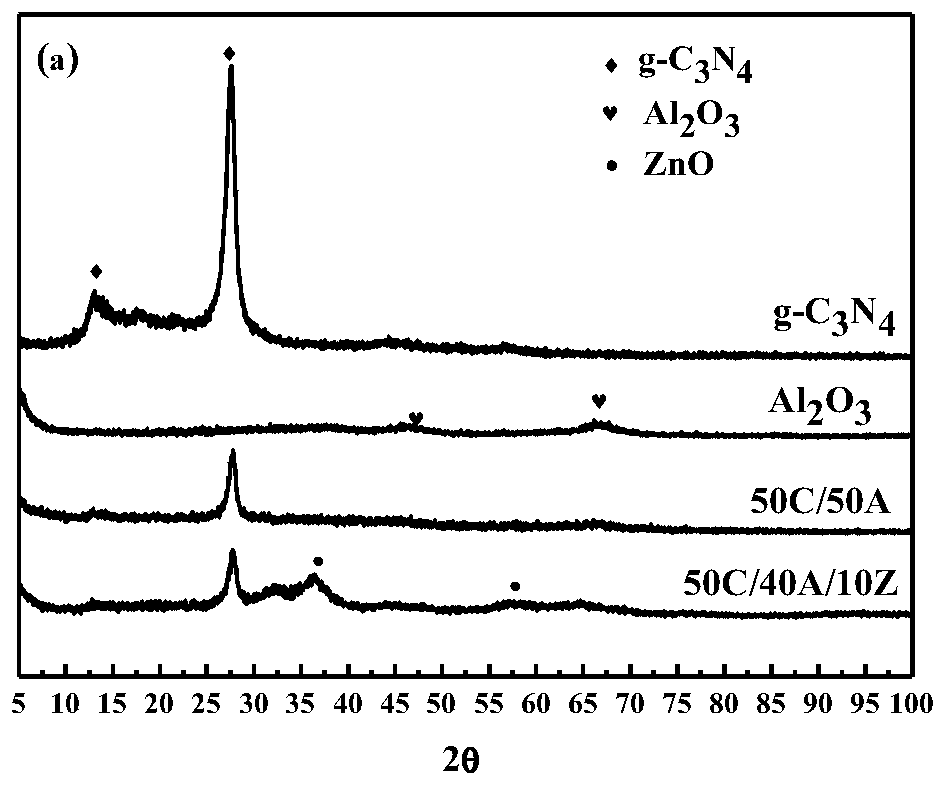

[0046] The samples were tested by XRD, UV-Vis DRS, FESEM and HRTEM respectively. The test patterns are shown in Fig. 1(a), figure 2 , image 3 and Figure 4 shown. Figure 1(a) XRD pattern shows that sampl...

Embodiment 2

[0071] Follow the steps below to prepare g-C 3 N 4 / Al 2 o 3 / ZnO (marked as 50C / 45A / 5Z) ternary heterojunction:

[0072] ①Dissolve 0.0053mol of aluminum nitrate in distilled water, then add 0.3g of g-C prepared in the laboratory 3 N 4 After stirring evenly, add 1mol / L NaOH solution dropwise to the beaker until pH=8-9, and continue stirring for 1 hour;

[0073] ②Dissolve 0.00036mol zinc nitrate in distilled water, and drop it into the turbid solution prepared in step ① simultaneously with 1mol / L NaOH solution, keep the pH=8-9, and continue to stir for 1 hour.

[0074] ③ Suction filter, dry, and grind the precipitate obtained in ② to obtain the precursor, which is calcined at 400°C to obtain the required sample 50C / 45A / 5Z.

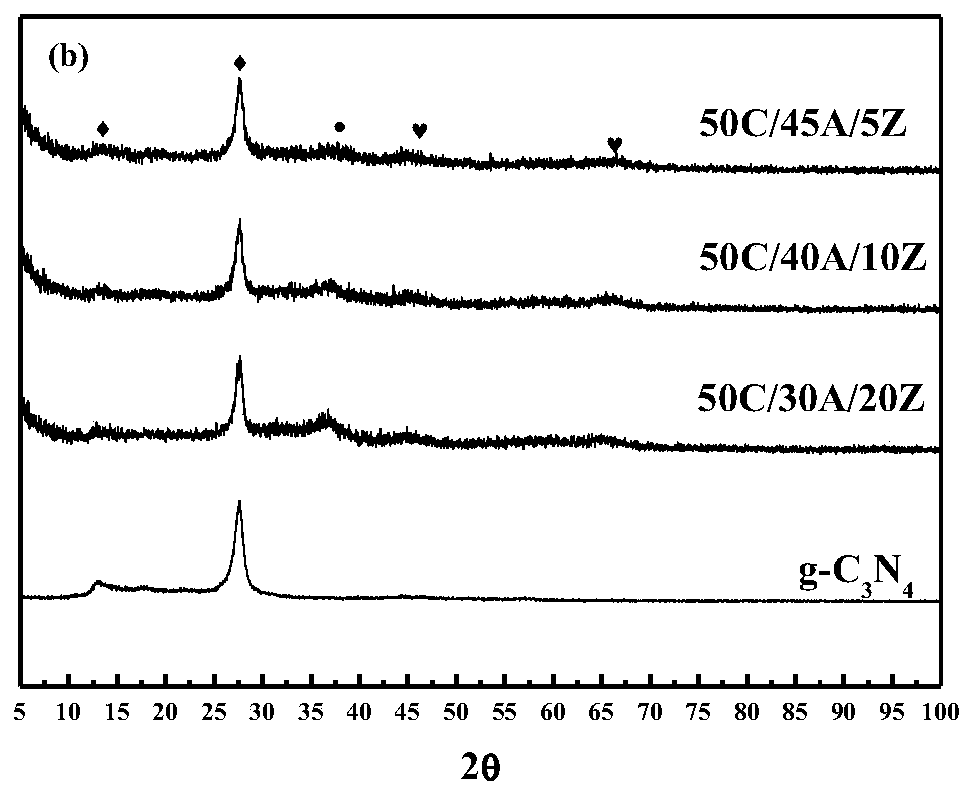

[0075] The samples were tested by XRD and UV-Vis DRS respectively, and the test patterns are shown in Figure 1(b) and figure 2 shown. Figure 1(b) XRD pattern shows that sample B consists of g-C 3 N 4 , ZnO and Al 2 o 3 Composed of three parts, d...

Embodiment 3

[0079] Follow the steps below to prepare g-C 3 N 4 / Al 2 o 3 / ZnO (marked as 50C / 30A / 20Z) ternary heterojunction:

[0080] ①Dissolve 0.0035mol aluminum nitrate in distilled water, then add 0.3g of g-C prepared in Example 1 3 N 4 After stirring evenly, add 1mol / L NaOH solution dropwise to the beaker until pH=8-9, and continue stirring for 1 hour;

[0081] ②Dissolve 0.00144mol zinc nitrate in distilled water, and drop it into the turbid solution prepared in step ① simultaneously with 1mol / L NaOH solution, keep the pH=8-9, and continue stirring for 1 hour.

[0082] ③ Suction filter, dry and grind the precipitate obtained in ② to obtain the precursor, which is calcined at 500°C to obtain the desired sample 50C / 30A / 20Z.

[0083] The samples were tested by XRD and UV-Vis DRS respectively, and the test patterns are shown in Figure 1(b) and figure 2 shown. Figure 1(b) XRD pattern shows that the sample consists of g-C 3 N 4 , ZnO and Al 2 o 3 It consists of three parts.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com