Amorphous Silicon/Microcrystalline Silicon Tandem Solar Cell Based on Periodic Array of Nanoholes

A technology of solar cells and periodic arrays, applied in the field of solar photovoltaics, can solve problems such as difficult processes, complex structures, and increased manufacturing costs of microcrystalline silicon bottom cells and entire stacked solar cells, so as to reduce volume, enhance absorption efficiency, and weaken The effect of photodegradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

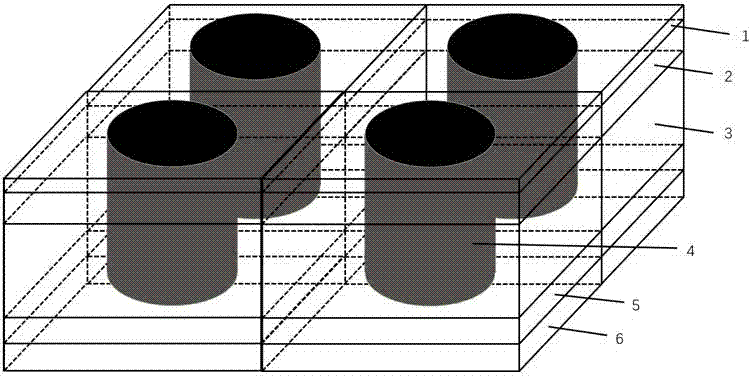

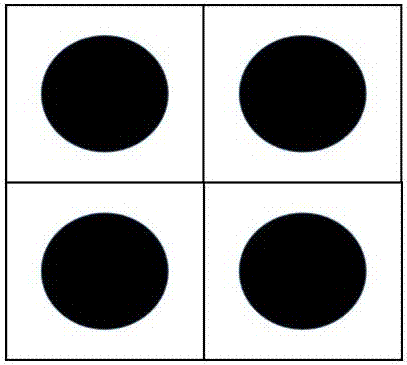

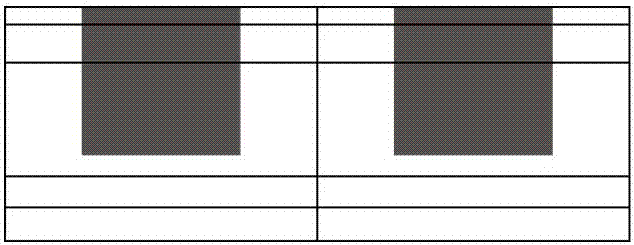

[0030] The top transparent electrode 1 is set to be zinc oxide with a thickness of 80 nm; the thickness of the amorphous silicon top cell 2 is 260 nm; the thickness of the microcrystalline silicon bottom cell 3 is 2 μm; the low refractive index nanohole periodic array 4 is silicon dioxide, The diameter is 300 nm, the depth is 1.94 μm, and the period is 500 nm; the bottom transparent conductive oxide 5 is zinc oxide, and the thickness is 80 nm; the metal back reflection electrode 6 is silver, and the thickness is 200 nm.

[0031] Figure 4 Shown are the absorption lines (solid lines) of the amorphous silicon top cell and the microcrystalline silicon bottom cell of the above example, and the amorphous silicon top cell and microcrystalline silicon of the planar amorphous silicon / microcrystalline silicon tandem solar cell The absorption line (dashed line) of the bottom cell. From Figure 4 It can be seen that after introducing a periodic array of nanoholes into the planar amorph...

Embodiment 2

[0033]The top transparent electrode 1 is set to be tin oxide, and the thickness is on the order of submicron; the thickness of the amorphous silicon top cell 2 is less than or equal to 300 nm; the thickness of the microcrystalline silicon bottom cell 3 is less than or equal to 2 μm; the low refractive index nanohole periodic array 4 Al2O3, its diameter and period are on the order of submicron, and the depth does not exceed the bottom of the microcrystalline silicon; the bottom transparent conductive oxide 5 is tin oxide, and the thickness is on the order of submicron; the metal back reflection electrode 6 is silver, and the thickness is sufficient thick, no light can pass through.

[0034] By selecting different materials and setting different structural parameters, the sub-cell light absorption efficiency and photocurrent of the amorphous silicon / microcrystalline silicon stack solar cell based on the periodic array of nanoholes of the present invention can be flexibly regulate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com