Treatment method of high-temperature dry distillation raw gas

A high-temperature dry distillation and treatment method technology, which is applied in the removal of gas pollutants, gas dust removal, combustible gas purification, etc. High utilization rate and high quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

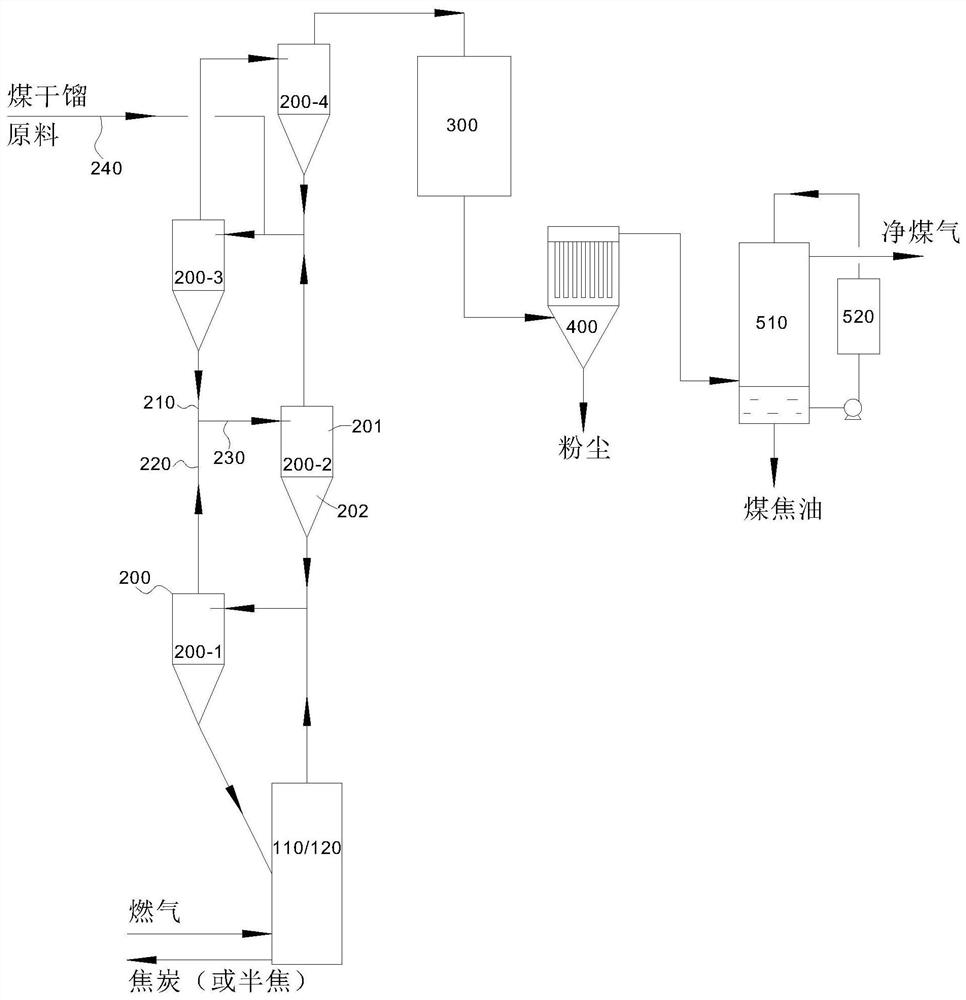

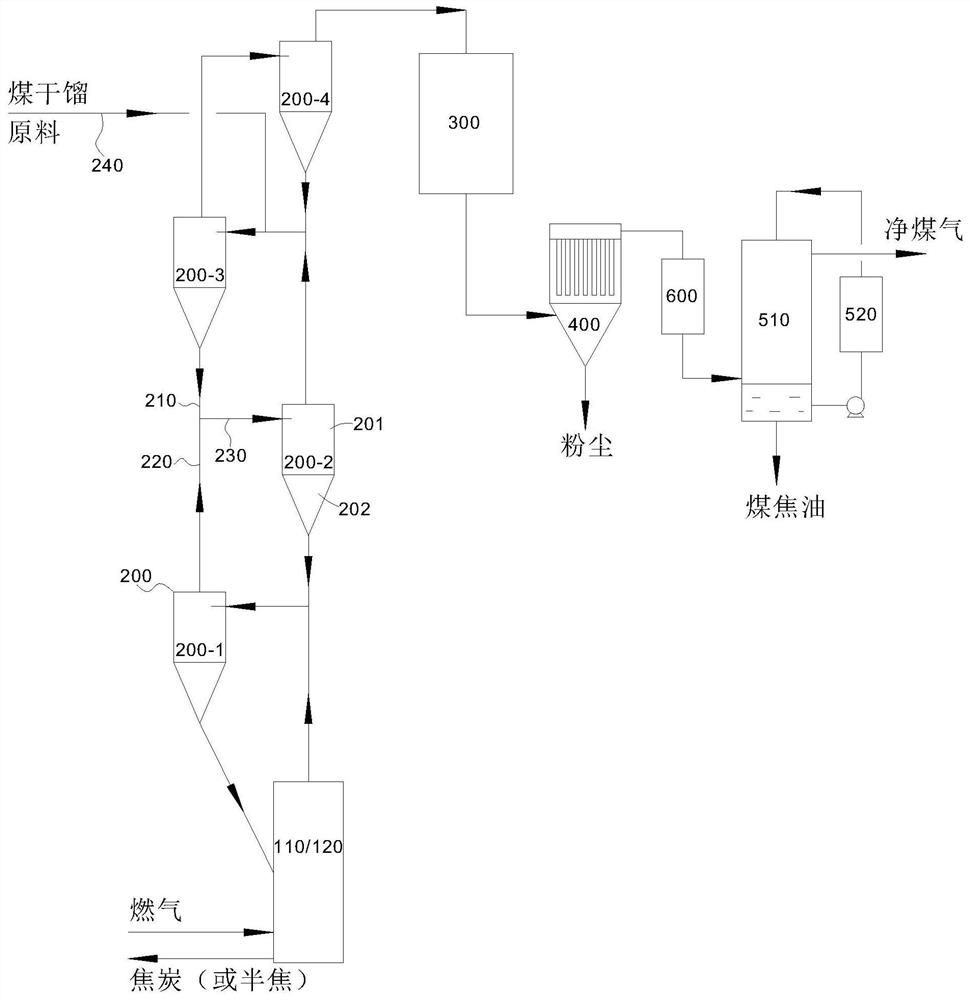

[0048] The first embodiment of the high-temperature dry distillation raw gas processing method of the present invention comprises the following steps:

[0049] (1) Pre-decomposing and pre-dusting the high-temperature dry distillation raw gas from the coal dry distillation rotary kiln or coal dry distillation furnace and the coal dry distillation raw material to output the first gas and solid; the coal dry distillation raw material is raw coal or oil shale;

[0050] (2) Drying the first gas and outputting the second gas;

[0051] (3) Carry out gas-solid separation treatment to the second gas, and output the third gas;

[0052] (4) Condensate the third gas to output coal tar and clean gas.

[0053] Wherein, in order to recover the heat of high-temperature dry distillation of raw coal gas as much as possible, but ensure that no coal tar is precipitated in the first gas, so that the oil and gas in the first gas are in a saturated state, the temperature of the first gas is 320-380°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com